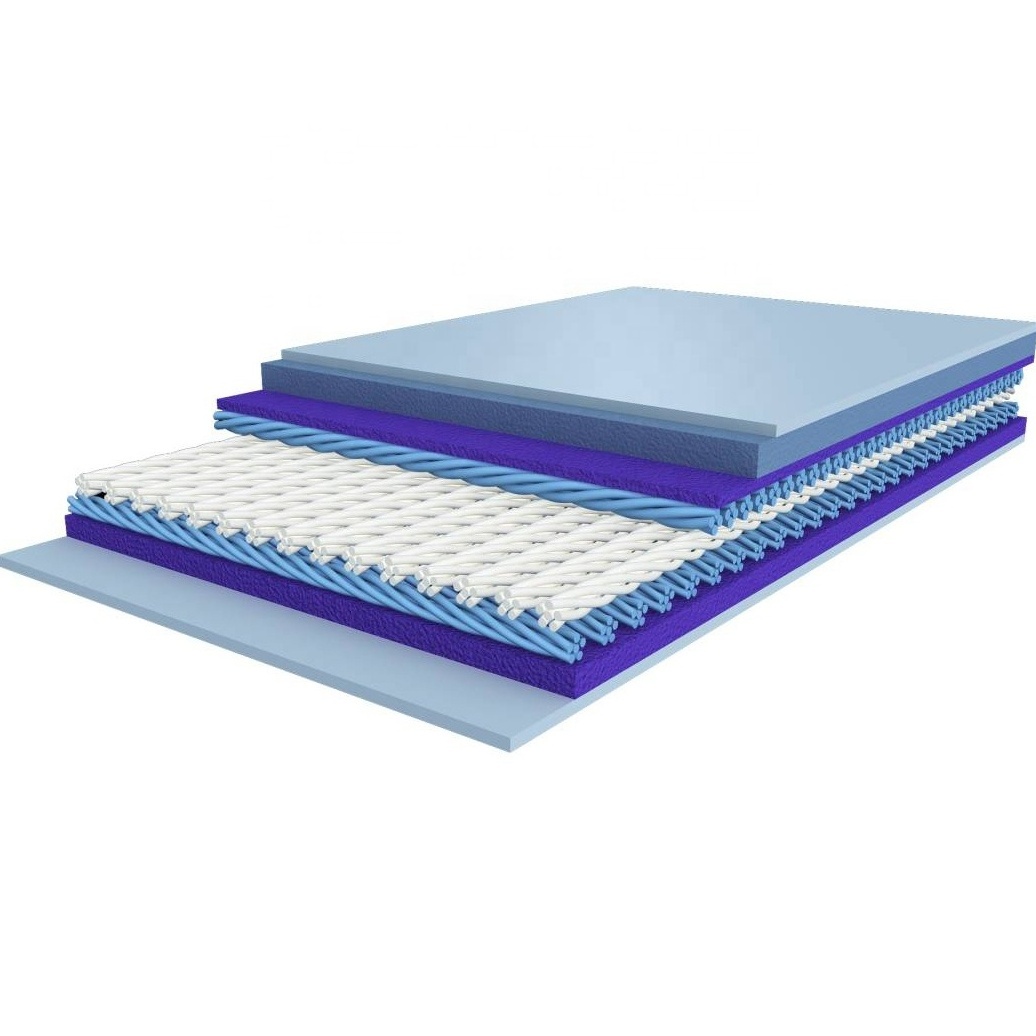

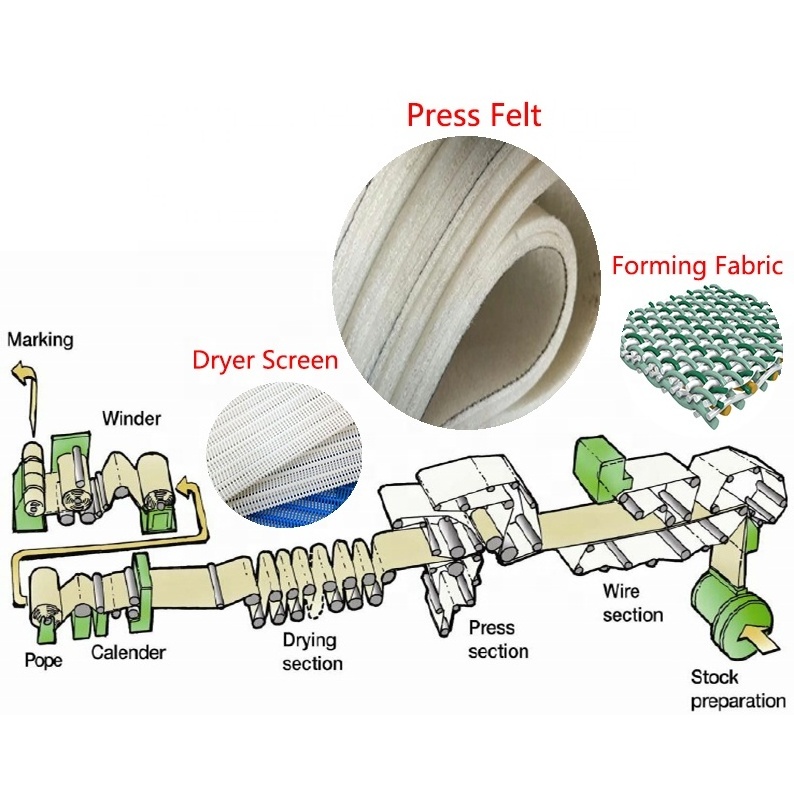

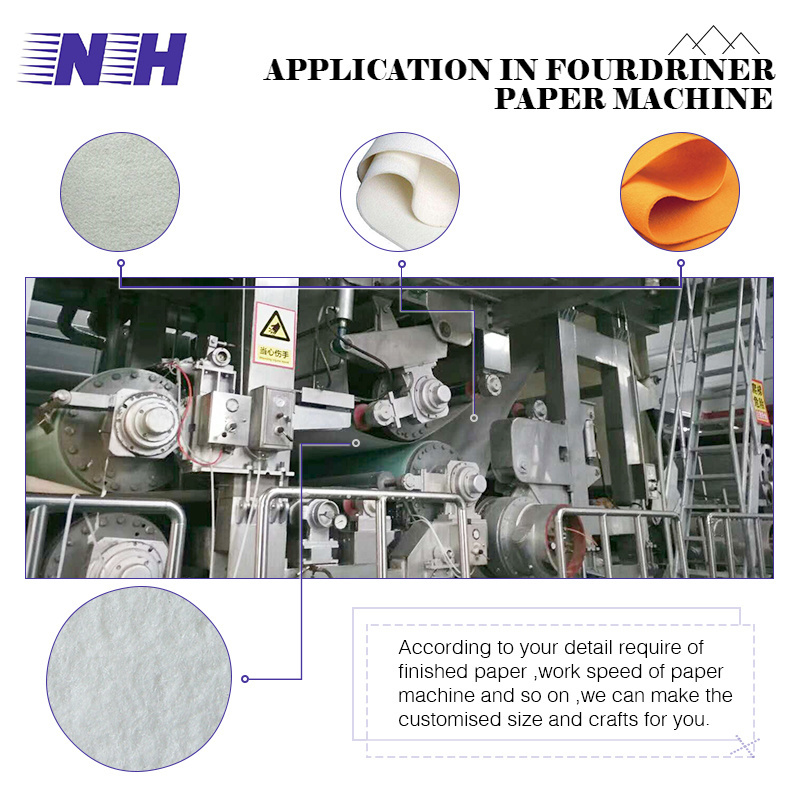

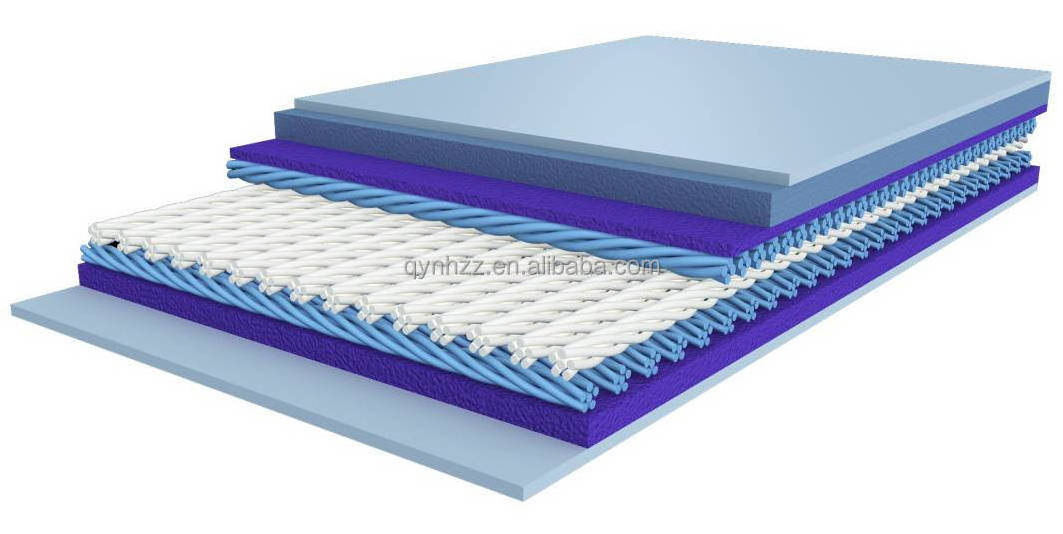

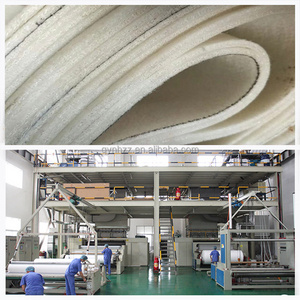

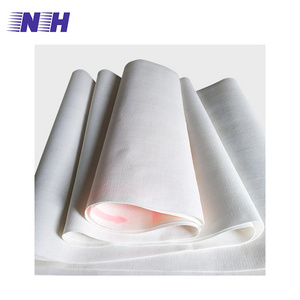

Paper Making Fabric Press Felt according to the location in the paper machine can be divided into wet paper making felt, paper making felt and dryer paper making felt. The wet paper making felt is run on the paper machine with the function of squeezing the paper blank so that it is dehydrated and the paper is smooth with high strength, low shrinkage, wear resistance, anti-bacterial and anti-acid corrosion feature . Paper making felt is used above wet paper making felt,connect to the dryer cylinder with small part of paper making felt,with the function of collar paper, top flat and dry .It is smooth, stiff, good elasticity, wear resistance, high temperature performance . Dry paper making felt covered dryer cylinder, running in hot and dry conditions, flat and dried the paper , with a solid, flexible, wear, high temperature performance.

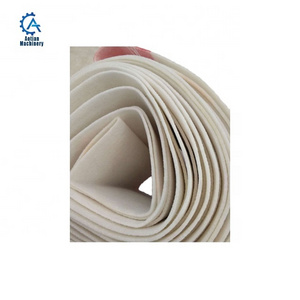

Paper Making Fabric Press Felt can also be used as canvas or breathable fabrics made of polyester filament. Paper-making felt divided into woven and knitted. Woven paper making felt using wool and nylon staple fiber blended yarn, blending ratio of about 75:25, by weaving, shrink it, fluff, drying and other processes made of stereotypes. The method of making the paper-making felt is to first fabricate 50% wool and 50% nylon staple fiber or 100% nylon staple fiber into a fibrous web, overlay the layers, and then use a barbed steel needle to staple the

web of the annular base fabric, to achieve a certain degree of tightness and flatness. Acupuncture methods are single-sided acupuncture and double-sided acupuncture. Acupuncture blanket with a good water treatment, wear, high strength, long service life

characteristics.