- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

UTron

-

Model Number:

-

UTron2005290000000031

-

Zn (Min):

-

90%

-

Shape:

-

Round, Plate, Tube, Bar, Ribbon or customize

-

Material:

-

Zinc Base Alloy

-

Color:

-

Silver

-

Standard:

-

ASTM

-

Technology:

-

Casting or extruded

-

Appearance:

-

Smooth

-

Size:

-

Customers' Requirement

-

Application:

-

Anti Corrosion Cathodic Protection

-

Sample:

-

Available

-

MOQ:

-

5 piece

Quick Details

-

Alloy Or Not:

-

Is Alloy

-

Powder Or Not:

-

Not Powder

-

Place of Origin:

-

China

-

Brand Name:

-

UTron

-

Model Number:

-

UTron2005290000000031

-

Zn (Min):

-

90%

-

Shape:

-

Round, Plate, Tube, Bar, Ribbon or customize

-

Material:

-

Zinc Base Alloy

-

Color:

-

Silver

-

Standard:

-

ASTM

-

Technology:

-

Casting or extruded

-

Appearance:

-

Smooth

-

Size:

-

Customers' Requirement

-

Application:

-

Anti Corrosion Cathodic Protection

-

Sample:

-

Available

-

MOQ:

-

5 piece

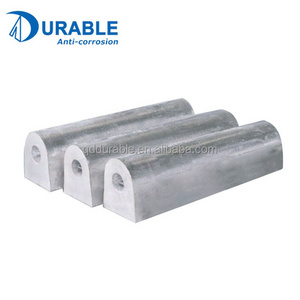

Zinc alloy anodes are particularly suitable for ballast tanks, the hull of ships, jetties, and subsea pipeline applications, etc. Zinc Alloy Anode is cast from high-grade zinc alloyed to ensure an even corrosion pattern, reliable electrical efficiency and long working life. The anodes are made to meet ASTM B418 type I standard and U.S. MIL-A-18001K.

Chemical composition:

|

Type |

Fe % (Max) |

Pb % (Max) |

Cu % (Max) |

Al % |

Cd % (Max) |

Others % (Max) |

Zn % |

|

I |

0.005 |

0.006 |

0.005 |

0.1-0.5 |

0.025-0.07 |

0.01 Max |

Remaider |

|

II |

0.0014 |

0.003 |

0.002 |

0.005 Max |

0.003 Max |

-- |

Remaider |

Type I: ASTM-B-418 TYPE I and MIL-A-1800 I J.

Type II: ASTM-B-418 TYPE II.

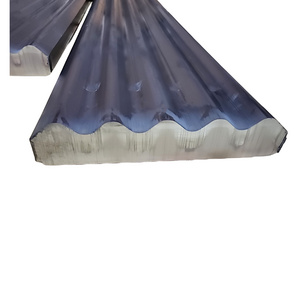

Packaging & Delivery

Packaging Details:

1. Inside: Kraft papers, plastic bags, polyethylene foamed sheet;

2. Outside: packing: wooden box;

3. Or according to customer requirement.

Packing Picture Example:

Port:

Tianjin, Shanghai, Qingdao or any other Chinese main port.

Lead Time:

2-15 days after payment confirmed.

Customize the Titanium Electrodes:

Utron has a professional technical team with decades of experience on titanium electrodes, coated titanium anodes; we can design the coating according to your specific working condition. Customize the operating life as per clients’ specific needs.

Develop New Products:

UTron has excellent innovative technical engineers help you to develop new products.

Consulting and Technical Assistance:

The sales engineers and technical engineers in UTron are professional; they have intrinsic knowledge of the world of cathodic protection, waste water treatment, electroplating and electrowinning. Feel free to contact them you have any queries. They are committed to improve your processes or to solve a tricky challenge that, given certain circumstances, might have never previously existed.

OEM:

UTron can produce as per clients’needs.

Tests:

UTron can provide the Accelerated Life Test, Coating X-Ray Test, Coating Thickness Test, Helium Leak Detection Test, Contact Resistance Test, Electrochemical Performance Test and other test.

Samples:

UTron can offer free or paid samples for test.

1. Can you give a quotation as per the product picture on your website?

Answer: Our anodes are non-standard products, most of them are in accordance with the requirements of the customer's specific requires. The application industries and countries are different, so please let your engineers or your customer's engineers to provide a specific size, anode working environment, usage, current density and life expectancy, so we can offer you specific price.

2. What is your internal inspection procedure, how do you inspect your products?

Answer: Re the internal inspection procedures, There are 6 steps: Material, mechanical processing, surface treatment, coating, cable connection and packing.

Every step has responsible leader, the inspector checks carefully every step with professional records, operation files, check subjects and performing programs. Once problems are checked out, steps will be taken to make up.

3. Do you have any certificate for your testes from any third party (like SGS, etc)? Or has any third party inspection company has ever tested your anodes and reported?

Answer: yes, we do have some test certificates from famous third party, like St Louis testing laboratory and china classification society etc.

4. The wooden case is too heavy; can I have other packing method such as carton box to save the freight cost?

Answer: Wooden cases are do heavy, but as per our years of export experience, carton box can make damage for the anode. Though wooden cases are heavy, but it will not damage the anode.