- Product Details

- {{item.text}}

Quick Details

-

The Machines classification:

-

cone crusher spare parts

-

Color:

-

Iron Grey

-

Spare Parts Supply:

-

Will Supply Any Time

-

Application:

-

Mining,Quarry,chemical industry and Construction

-

Test&Installation:

-

Professional Engineer Assigned

-

Certification:

-

CE

-

vist workshop:

-

any time you can

-

production time:

-

new

-

machine name:

-

cone crusher

Quick Details

-

Weight (KG):

-

2

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

SBM

-

The Machines classification:

-

cone crusher spare parts

-

Color:

-

Iron Grey

-

Spare Parts Supply:

-

Will Supply Any Time

-

Application:

-

Mining,Quarry,chemical industry and Construction

-

Test&Installation:

-

Professional Engineer Assigned

-

Certification:

-

CE

-

vist workshop:

-

any time you can

-

production time:

-

new

-

machine name:

-

cone crusher

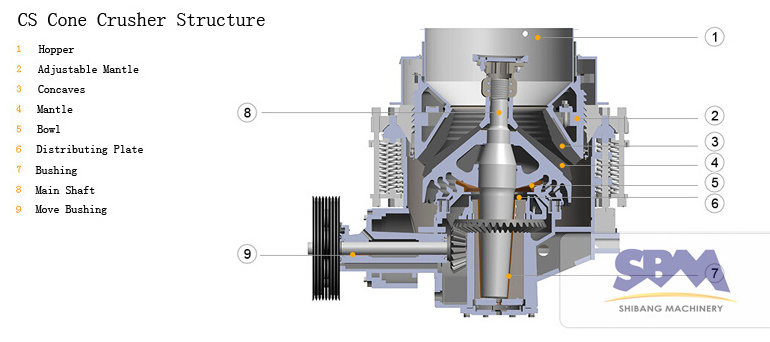

What is the detail of cone crusher spare parts?

Comparing with other kinds of crushers, CS Series spring cone crusher is quite excellent in hard material crushing and the final product has good sharp. The innovations like stable lubrication system and excellent sealing system evidently reduce the production cost, helping you to achieve the highest level of profitability.

Gear

Gear is installed at the top of Eccentric Bearing Bush, connecting the small gear of transmission shaft. Many reasons may cause some damages of Gear, as a result, the whole machine will break down and must be dismantled in time.

Spring

Springs are installed around theCS series cone crusher; they are easy to be found from outside. Supposing anyone of the springs is broken, the performance of the crusher will be greatly affected, it must be replaced in this situation.

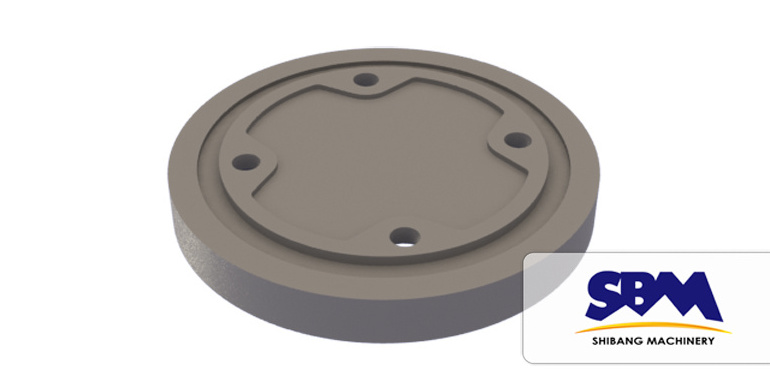

Distributing Plate

Distributing Plate is installed at the top of main shaft, in the center of hopper of cone crusher. When materials are fed to cone crusher, they will impact this part, then they are distributed to crushing cavity, as a result, the Distributing Plate is abraded quickly.

Slab

Slabs are installed at the transoms under the crushing cavity, belonging to one part of the lower machine frame. When minerals or rocks are crushed, fall to hoppers or belt under the cone crusher. Slabs prevent materials impact the lower machine frame efficiently.

Belt Wheel

Belt Wheel is installed at the outside of cone crusher, connecting the driving belts; it is the key transmission. Once the Belt Wheel is damaged, the whole machine has to break down, there is no choices but replace a new one.

Bushing

Bushing is installed between the main shaft and eccentric sleeve assembly. It reduces the abrasion of main shaft efficiently and extends the service life of main shaft. Also, it ensure the machine work very well.

Mantle

Mantle is installed at the bottom of cone crusher crushing cavity, under the Concave. It is one of the chief wear parts of cone crusher. For all materials are crushed between Concave and Mantle, it is abraded faster than other parts.

Concave

Concave is installed on the top of cone crusher crushing cavity, above the Mantle. It is one of the chief wear parts of cone crusher. For all materials are crushed between Concave and Mantle, it is abraded faster than other parts.

Main Shaft

Main Shaft is installed at the center of cone crusher, easy to be found. If the machine loose balance or the lubricating work is ignored, the main shaft may break out, so operators should examine it regularly.

1."small parts are wooden box package"

2."the major machine nude packing, container, or upon customers' requirement"

3."export standard"

We can not only provide the good machines, but also wholeheartedly provide the comprehensive for our clients. The series of professional technology service will make you have an excellent product experience.

Pre-sales Service:

The wide product range enables us to provide our customers with individual machines or complete processing plants. Based on our customers’ request and budget, our experts make efficient, reliablesolutions, and we produce strictly follow customers’ order. What’s more, every customer has the chance to visit the working machine in the site before placing the order.

Most of the visiting foreign customers feel inconvenient for the first time. Due to this condition, we help to arrange cars, hotels, and translators for every visiting customer.

After-sales Service:

Experienced technicians guidance is available on the phone, and on the internet. One or more engineers will be dispatched to the quarry site to help install the customers’ plants. Necessary training about machine daily maintenance to local workers is provided also.

After-Sales department is made of well-trained employees, and installation engineers. The installation technicians are special and professional team of SBM; they are now strategically located home and abroad, working for our customers

.