Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Hegu Plastic Machinery Machine

-

Voltage:

-

380V/3P/50HZ

-

Dimension(L*W*H):

-

20M*2M*4M

-

Power (kW):

-

90

-

Weight:

-

20 KG

-

Raw material:

-

PVC PP PE Resin or Recycled Plastic and Plant Fiber

-

Brushing:

-

WPC brushing machine

-

Sanding:

-

WPC sanding machine

-

Embossing:

-

WPC embossing machine

-

Automatic Grade:

-

Automated WPC Polymer Machine

-

Power:

-

37KW

-

products:

-

wpc profiles board

-

Extruder:

-

Conical Double Screw Extruder

-

Extrudr model:

-

SJMS65/132 +SJMS92/188

-

Motor brand:

-

Siemens Bede

-

Marketing Type:

-

Hot Product 2019

Quick Details

-

Screw Design:

-

Double-screw

-

Screw L/D Ratio:

-

22:1

-

Screw Speed (rpm):

-

90 rpm

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Hegu Plastic Machinery Machine

-

Voltage:

-

380V/3P/50HZ

-

Dimension(L*W*H):

-

20M*2M*4M

-

Power (kW):

-

90

-

Weight:

-

20 KG

-

Raw material:

-

PVC PP PE Resin or Recycled Plastic and Plant Fiber

-

Brushing:

-

WPC brushing machine

-

Sanding:

-

WPC sanding machine

-

Embossing:

-

WPC embossing machine

-

Automatic Grade:

-

Automated WPC Polymer Machine

-

Power:

-

37KW

-

products:

-

wpc profiles board

-

Extruder:

-

Conical Double Screw Extruder

-

Extrudr model:

-

SJMS65/132 +SJMS92/188

-

Motor brand:

-

Siemens Bede

-

Marketing Type:

-

Hot Product 2019

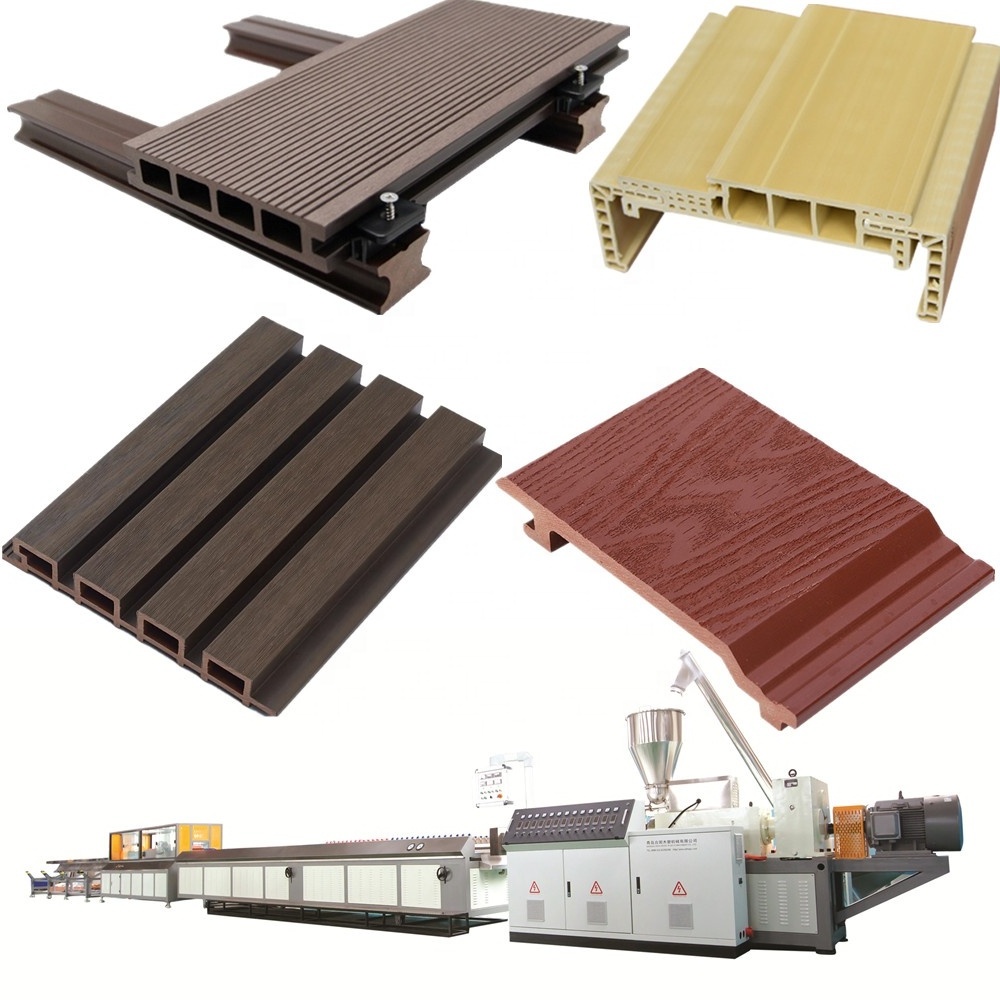

Outdoor exterior wooden grain PVC WPC wall panels extruder 3D embossing PP PE plastic wood composite cladding machine

|

Plastic

|

Formulation

|

Final Product

|

|

PVC

|

10%-50% wood powder or natural fiber,50%-90% PVC

|

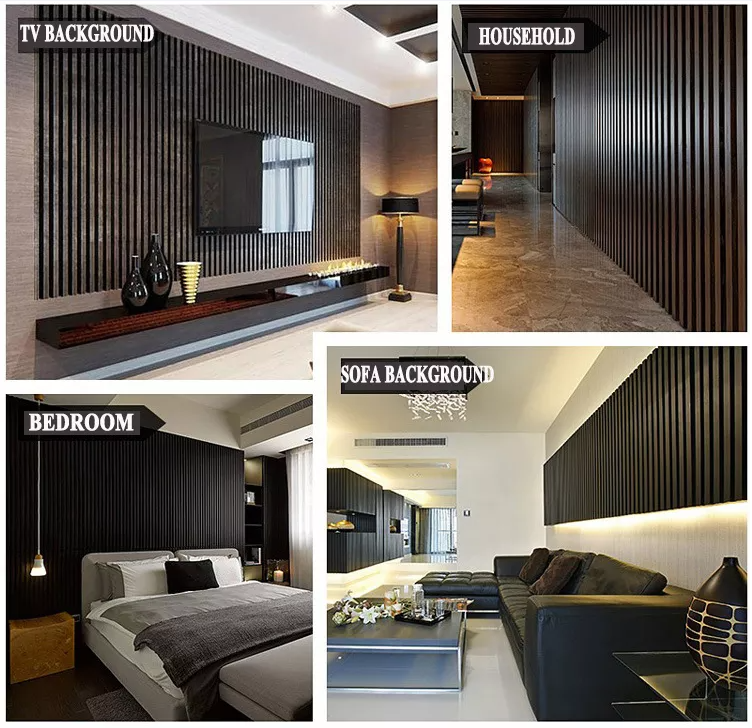

Door Frame, Door Board, Furniture Board, Decoration Board, Wall Panel etc

|

|

PP/PE

|

50%-70% Wood powder or natural fiber, 30%-50% PP/PE

|

Railing, Fencing, Decking, Flooring, Pillar, etc

|

We have different type of WPC machines to make different WPC products from different raw material,such as:

1, PP PE WPC profile machine:

Material: recycled 30% PP/HDPE+70% wood powder+chemical additives.

Product: WPC decking, WPC wall cladding, WPC fence, WPC pergola..

2, PVC WPC profile machine:

Material: 50%PVC+20% wood+20% caco3+ Chemical additives.

Product: WPC door frame, WPC wall panel, WPC decoration profiles indoor.

3, PVC WPC door machine:

Material:50% PVC+20% wood+20% caco3 +Chemical additives.

Product: Hollow Door panel, Cabinet Door, and other big profiles

4, PVC WPC board machine:

Material: 60% PVC+10% wood +20% CaCo3+ Chemical additives.

Product: Solid door panel, Furniture board, partition wall panel, decoration solid panel.

1,PE WPC Cladding /wall panel /fence/ decking making machine

HGMSE series PP/PE WPC profile production line can continuously produce PP/PE WPC profile. The WPC profile adopts two -step production process. The granulating machine make WPC pellets using PP/PE recycled materials, wood powder and auxiliary agent. Then use this production line produce WPC profile.Customers can choose embossing machine for the production line to achieve 3D pattern performance.Customers can also make PE WPC single color or double color co-extrusion profile by adding extruders.The profile produced by this production line can be sanded and brushed by sanding machine and brushing machine.

2. 1 PVC WPC Door frame profiles making machine

2.2 WPC solid door frame machine with ASA co-extrusion wooden surface

With advantages of high quality, stably production, good service and good price, Our WPC solid and hollow door frame machine has been good accepted by our customers. We have also developed our own technology for making new WPC door frame products.

Hereby we would like to introduce our WPC+ASA co-extrusion technology:

1, with ASA coating wooden grain layer, the WPC profile can be used outside even under sunshine, the ASA material is specially for color profile with good weather resistance.and with our this technology, we could make the outer ASA layer into wooden grain color which has better quality and low cost comparing with lamination.

2, we can make three sides or even four sides online embossing for the WPC profile, which can provide nature wooden skin feeling on the WPC profile surface.

2.3 The new LVL wood core WPC profile making machine

Qingdao Hegu Wood Plastic Machinery co.,ltd is one of the earliest manufacturer to develop the WPC extruder machines.We constantly research and improve our machines to bring better products to our customers.

For adopting the Indian market requirements, we have developed special technology for making low cost and high quality WPC+LVL door frame by co-extrusion technology.This new project has been successfully tested.

Advantage of LVL Wooden core WPC profile

1,Stably production, avoid deformation:

2, higher production speed:

3, Better nail/screw holding strength, high strength, high toughness

So the WPC+LVL co-extrusion door frame can be made with both advantages of LVL and WPC, it is water proof, fire proof, insect proof, high strength, high toughness,high nail/screw holding strength,smooth and beautiful outlook which can be embossed/laminated/painted

3, Hollow PVC WPC door panel making machine

The WPC door is made from PVC and wood composition, it includes WPC door panel making machine and WPC door frame making machine.

We are professional for the the complete production line including WPC door material mixing machine, WPC door panel extrusion machine, WPC door frame extrusion machine, WPC door panel lamination machine,WPC door frame lamination machine, WPC door cutting machine, WPC door engraving machine.

4,PVC WPC foam board making machine

PVC WPC skinning, semi-skinning foam board extrusion line adopt specialized SJSZ conical twin screw extruder. It adopts imported ABB and Siemans speed frequency converter and RKC, Omron temperature control device. It has the features of extensive adjusting range high precision of temperature control, easy operation etc. The auxiliary machine is composed of calibrating stage, hau-off, edge cutter transverse cutting machine and tilt stacker. The mould is equipped with moulds temperature cooling device to ensure the effect of surface forming. The roller tractor(8 pairs) adopted imported speed reduction motor and frequency changer. It possesses the features of reasonable structure, large traction strength, stable traction, etc. The cutter has the Character of being reliable, accurate, high cutting precision, etc. The push rack equipped with movable material pushing device and specially designed rubber protective layer. It has the feature of no destraction on the materials easy operation, etc. The auxiliary machine units adopts programmable computerized controlling system to guarantee reliable and stable complete machine control.

5, PE WPC board making machine

The wood-plastic is a new kind of synthetic material which uses PVC,PP,PE resin or recycled plastic and plant fibre ( wood powder,chaff,straw etc.) as raw material and through the process of mixing,exrusion,calibrating,drawing off and cutting. This kind of wood-plastic materials are not only very similar with natural wood in appearance and feel,but also with the same characteristics as wood of excisable, planeable,sawable, unmatched grip,low bibulous rate, good moisture resistance, mothproof,mildew resistance,good resistance to acid and alkali,anti-corrosion, and it has the feature of fire resistance.The products are non-toxic,non-polluting,environment-friendly and save-energied, without formaldehyde, benzene and ammonia and other harmful substances.The wood-plastic products are widely used in outdoor floor,hydrophilic construction,balcony,landscape architecture,chairs and benches, fences, indoor doors and windows, furnitures, etc.

Qingdao HEGU Wood Plastic Machinery co.,ltd

We have WPC R&D and debugging team.

Customized machine according to customer's requirements.

Turnkey project service for whole WPC production line.

All series WPC machines in factory free testing anytime.

We help new customers succeed in WPC projects.

Thousands of production lines sold in more than 50 countries.

Choose WPC machine, choose professional manufacturer Hegu.