- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

Local site

-

Weight:

-

1850 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Material:

-

Q235

-

color:

-

up to you

-

screen layer:

-

1-4

-

capacity(t/h):

-

30-810

-

Quality control:

-

go through five checks

-

spare parts:

-

supply by us

-

After sale service:

-

the whole using life

-

delivery time:

-

quickly and in time

-

Certification:

-

ISO9001:2008,BV,CE

Quick Details

-

Type:

-

Circular

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

XKJ

-

Voltage:

-

Local site

-

Weight:

-

1850 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Material:

-

Q235

-

color:

-

up to you

-

screen layer:

-

1-4

-

capacity(t/h):

-

30-810

-

Quality control:

-

go through five checks

-

spare parts:

-

supply by us

-

After sale service:

-

the whole using life

-

delivery time:

-

quickly and in time

-

Certification:

-

ISO9001:2008,BV,CE

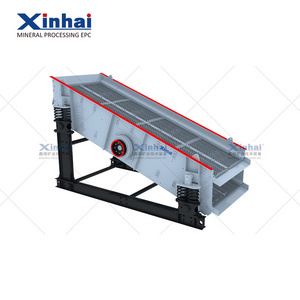

Rotary Vibrating Screen introduction :

Vibrating screen of Xingyang Mining Machinery Manufactory is a kind of new screening equipment, the vibrating track is a circle, and it is designed for especially screening stone stock of quarry, and also for classifying products of such departments as coal separator, mineral processing, building materials, electricity and chemical industry, etc. The output and energy consumption of our circular vibrating screen reach the national standard. It is advanced at home and abroad, and is well accepted by customers.

3.Circular Vibrating Screen adopts tire clutch with capability of flexible connection and stable operation.

4.Circular Vibrating Screen adopts the structure of small amplitude, high frequency, large obliquity to make the screen hold the capability of high efficiency, large handling capacity, long life span, low consumption, little noise.

Rotary vibrating screen has the following features:

1. new structure ,advance technical data, high processing capacity and high screening efficiency

2.Circular Vibrating Screen adopts tube-type eccentric shaft vibration exciter and partial block of conditioning amplitude; easy operation and maintenance.

3. Circular Vibrating Screen with spring steel woven mesh or perforated metal sieve, long life, not easily plug holes.

4. Circular Vibrating Screen with rubber isolation springs, long life, low noise, and pass through resonance region easily.

Vibrating screen delivery photos :

Technical data:

After-sale services

We have advanced production technology and management. Our professional engineers and after-sales groups can offer optimum service for our customers.

Pre-sale services

1. Select equipment model;

2. Design and manufacture products according to clients' special requirement;

3. Train technical personnel for clients

Services during the sale

1. Pre-check products before of delivery;

2. Help you to draft solution.

After-sales service

1. Assist you to prepare for the first construction scheme;

2. Install and debug the equipment;

3. Train the first-line operators on site;

4. Examine the equipment regularly;