- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

110V 220V/50Hz 60HZ

-

Power:

-

300

-

Dimension(L*W*H):

-

720*630*2700

-

Weight:

-

160

-

Product name:

-

lab heating equipment

-

After-sales Service Provided:

-

Online support

-

Application:

-

Labs Research

-

Material:

-

SS304

-

Glass Material:

-

Borosilicate Glass 3.3 (GG-17)

-

Heating method:

-

Thermal Oil Bath

-

Function:

-

Reaction Process

-

Feature:

-

Digital Display

-

Mixing Type:

-

Anchor Agitator

-

Reaction Flask:

-

10L~100L

Quick Details

-

Capacity:

-

10L~100L

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Yuhua

-

Voltage:

-

110V 220V/50Hz 60HZ

-

Power:

-

300

-

Dimension(L*W*H):

-

720*630*2700

-

Weight:

-

160

-

Product name:

-

lab heating equipment

-

After-sales Service Provided:

-

Online support

-

Application:

-

Labs Research

-

Material:

-

SS304

-

Glass Material:

-

Borosilicate Glass 3.3 (GG-17)

-

Heating method:

-

Thermal Oil Bath

-

Function:

-

Reaction Process

-

Feature:

-

Digital Display

-

Mixing Type:

-

Anchor Agitator

-

Reaction Flask:

-

10L~100L

Recommend products

Our Company

Product Description

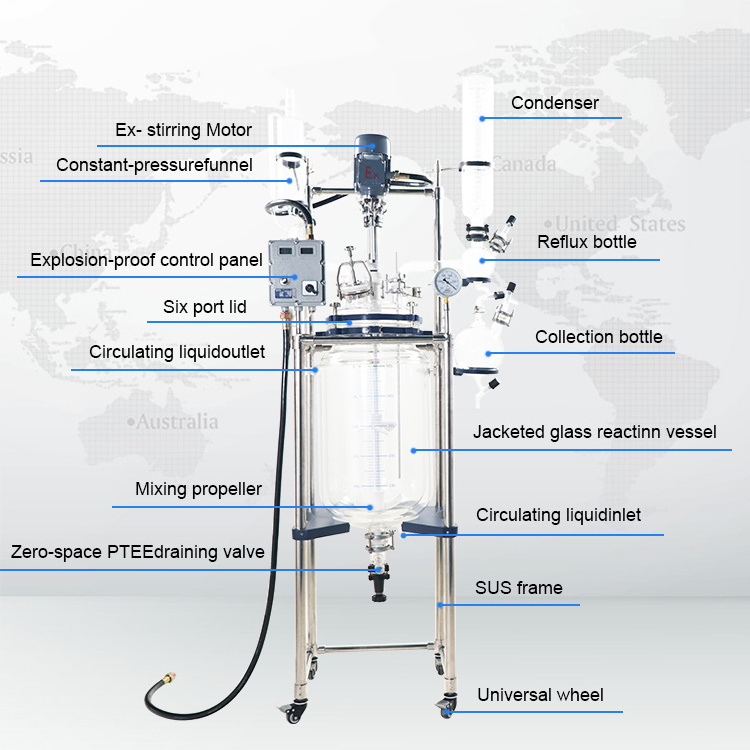

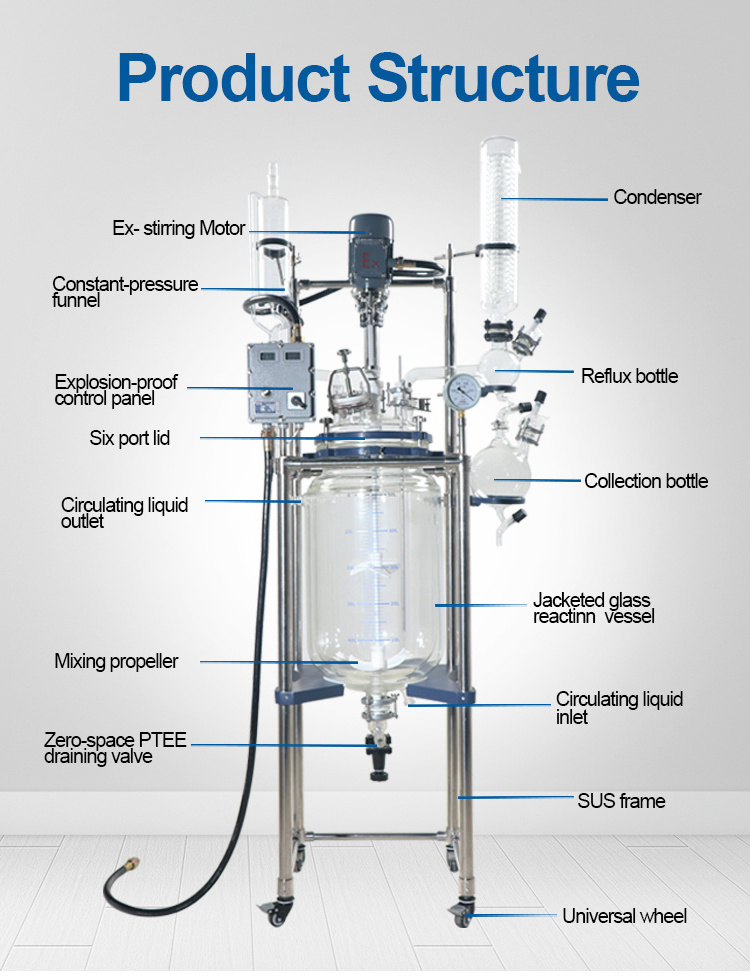

YUHUA

Lab Heating Equipment 200 Liter Glass Reactor 200L Price

YUHUA Pilot Plant Filter Reactor is designed to fulfil demanding crystallization and filtration processes.

Integrating the functionality of a reactor a filter in one system, a full crystallization process can be performed in the reactor without ever opening the vessel.

Processes range from crystal formation, filtration, product washing and drying.

Large quantities of crystalline product can be processed easily and safely in the YUHUA Pilot Plant Filter Reactor, making it ideal for process development, kilo lab and pilot scale production.

Products Show

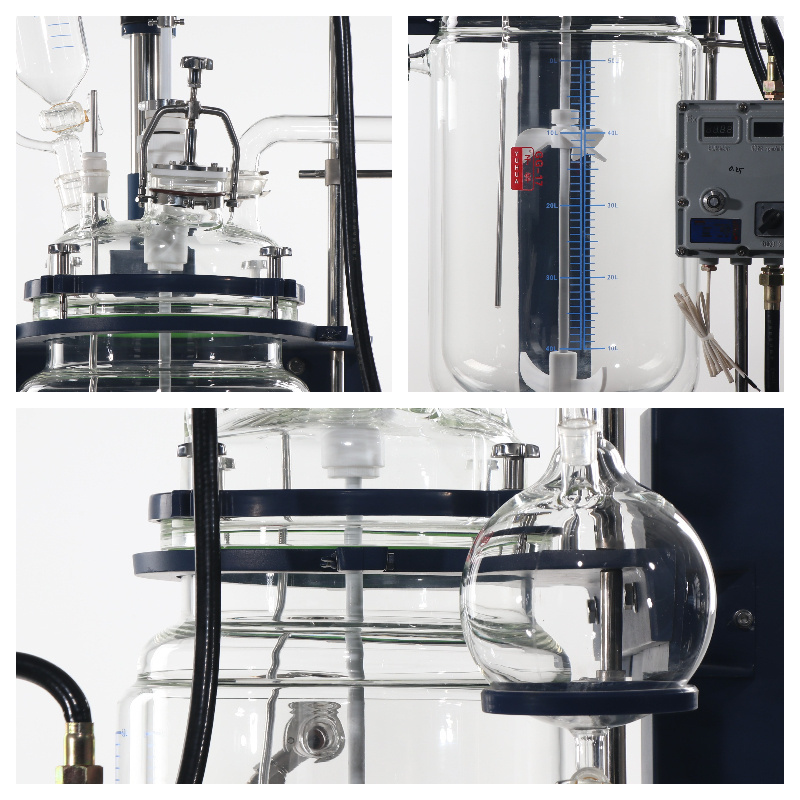

operational principle:

The double-layer glass reactor has a stirring system, condensation, drip addition, reflux, and collection system. The inner layer is equipped with a reaction solvent for stirring reaction, and the interlayer is circulated through a cold and heat source to provide high-temperature reaction (up to 300 ℃) or low-temperature reaction (up to -80 ℃). When heating the material, the evaporation efficiency can be improved under vacuum conditions (vacuum device needs to be connected), When the solvent vapor is cooled into a liquid through a glass condensation coil (requiring connection to a cooling device), it can flow back into the kettle or be recovered through the lower valve of the reflux elbow. After the reaction is completed, the material can be discharged from the side discharge port at the bottom of the pot. And the fully transparent reaction process is clear at a glance, making it an ideal experimental pilot equipment for modern biopharmaceuticals, fine chemicals, and new material synthesis.

Product features

1

)

This product has unique equipment and a stainless steel frame structure (with exquisite three-way and four-way connections), which is compact, sturdy, and easy to move.

2

)

The parts in contact with the materials are all made of high borosilicate glass (with a coefficient of expansion of 3.3) and polytetrafluoroethylene materials, which have stable performance and are not easy to react with the materials, making them convenient and safe to use.

3

)

Unique frequency conversion speed regulation allows you to operate at high and low speeds in practice, with ideal accuracy and ease. It can be equipped with a fully explosion-proof system, dual display explosion-proof box digital display of speed and material temperature inside the kettle, stable performance, clear display of control and data plane, simple and easy to operate.

4

)

The mixing system adopts ceramic bearings and mechanical seals to prevent wear and debris from the mixing rod. It is resistant to high temperature, wear-resistant, and has a good sealing effect.

5

)

Adopting PT100 temperature sensor and glass thermometer sleeve.

6

)

The vacuum pressure gauge displays real-time vacuum and the pointer displays.

7

)

Crescent type stirring blade, 304 stainless steel+PTFE stirring blade; The material of the mixing rod is 304 stainless steel. Outsourced PTFE pipes have high strength and strong corrosion resistance.

8

)

Glass+PTFE discharge valve, no liquid accumulation side discharge, very fast solution recovery.

9

)

There is a universal wheel with brakes at the bottom of the machine, which can move as a whole and is easy to operate.

|

Glass Materials

|

High Borosilicate Glass 3.3

|

|

|

|

|||

|

Wetted Parts

|

Glass and PTFE

|

|

|

|

|||

|

Reaction Vessel Capacity

|

1L, 2L, 3L, 5L, 10L, 20L, 30L, 50L, 80L, 100L, 150L, 200L

Vertical Baffles inside of the vessel (Optional) |

|

|

|

|||

|

Thermal Jacket

|

Ring Baffles within the Thermal Jacket (10L, 20L, 30L, 50L, 80L, 100L, 150L, 200L)

Full Jacket Design (10L, 20L, 30L, 50L, 80L, 100L, 150L, 200L)

|

|

|

|

|||

|

Filtration Area

|

ID215 Flange: 1,385 cm² (5L, 10L, 20L, 30L, 50L)

ID280 Flange: 2,462 cm² (30L, 50L, 80L, 100L)

ID400 Flange: 5,024 cm² (50L, 80L, 100L, 150L, 200L)

|

|

|

|

|||

|

Filtration Micron

|

Micron: 0.2μm to 200μm (depends on your materials) Filtration Materials: PTFE

Note: Not included by default |

|

|

|

|||

|

Stirring Motor

|

DC Brushless Motor, 50W, 100W, 150W AC Motor with Gear Reducer: 120W ~ 1500W

Explosion-Proof Motor: 180W, 250W, 370W, 550W, 750W, 1500W Stirring Range: 0 ~ 800 RPM Realtime Display: Mixing Speed, Materials Temperature |

|

|

|

|||

|

Mixing Sealing

|

PTFE + Mechanical

|

|

|

|

|||

|

Condenser

|

Cooling Coil Condenser

|

|

|

|

|||

|

Dropping Feeding Funnel

|

Dropping Feeding Funnel with PTFE Metering Valve and Equalizing Arm

|

|

|

|

|||

|

Glass Lid

|

Diameter: DN215, DN280, DN400 for your selection

7 Openings: 1) Dropping Feeding Funnel 2) Solid Materials Feeding 3) Stirrer 4) Liquid-Feeding 5) Temperature Probe 6) Condenser Reflux 7) Reserved (By default: Pressure Release) 8) Spray Cleaning or PH measurement (Optional) |

|

|

|

|||

|

Stirring Impeller

|

PTFE Anchor Type PTFE Pitched Paddle Type

PTFE Frame Type |

|

|

|

|||

|

Operating Temperature

|

-90℃ to +230℃

|

|

|

|

|||

|

ΔT - Thermal Shock Resistance

|

90℃ (Double Wall)

|

|

|

|

|||

|

Operating Pressure

|

Full Vacuum to Atmospheric Pressure

|

|

|

|

|||

|

Operating Jacket Pressure

|

Up to +0.5 bar (0.05 MPa)

|

|

|

|

|||

|

Power Supply

|

100V ~ 240V, 50Hz/60Hz

|

|

|

|

|||

Detail Specs

|

Item No.

|

YSF-10L

|

YSF-20L

|

YSF-50L

|

YSF-100L

|

|

Vessel Capacity(litre)

|

10L

|

20L

|

50L

|

100L

|

|

Jacketed Layer Capacity(L)

|

3L

|

5L

|

16L

|

30L

|

|

Motor Power(W)

|

EX120/300 W

|

EX180/300W

|

EX180/300W

|

EX550/300W

|

|

Stirring Speed(rpm/M)

|

0~650

|

0~600

|

0~600

|

0-600

|

|

Stirring Shaft Diameter(mm)

|

Φ15mm Blade Span 160mm

|

Φ15mm Blade Span 205mm |

Φ17mm Blade Span 205mm

|

Φ17mm Blade Span 250mm

|

|

Motor Torque(g/cm)

|

1000

|

1200

|

1500

|

1800

|

|

Machine Size(cm)

|

65L*60W*205H

|

85L*65W*215H

|

85L*65W*245H

|

90L*72W*280H

|

|

Packaged Size(cm)

|

142L*65W*61H

|

158L*71W*71H

|

178L*71W*71H

|

198L*80W*75H

|

|

Machine weight(kg)

|

76

|

94

|

124

|

138

|

Packing & Delivery

We are experienced in the whole packing and shipping process, and we will be responsible for any damage made during shipping and send clients replacements for free.

* Sufficient inner protection with different materials, including bubble bag, foam board and others.

* Qualified wooden package or carton for different products or as customer require

* Strict packing process to ensure the safety and completeness of the goods

Our Certifications

FAQ

Q: Are you trading company or manufacturer?

A: We are professional manufacturer of lab equipment and we have our own factory.

Q: How long is your delivery time?

A: Generally it is within 3 working days after receiving the payment if the goods are in stock. Or it is 5-10 working days if the goods are not in stock, depending on order quantity.

Q: Do you provide samples? Is it free?

A: Yes, we could offer the sample. Considering the high value of our products, the sample is not free, but we'll give you our best price including shipping cost.

Q: What is your terms of payment?

A: Payment<=15,000USD, 100% in advance. Payment>=15,000USD, 50% T/T in advance, balance before shipment.

(If you concerned about payment security for first order, we advise you can place Trade Assurance Order via Alibaba. You will get 100% payment refund if we can’t meet agreed delivery time.)

Hot Searches