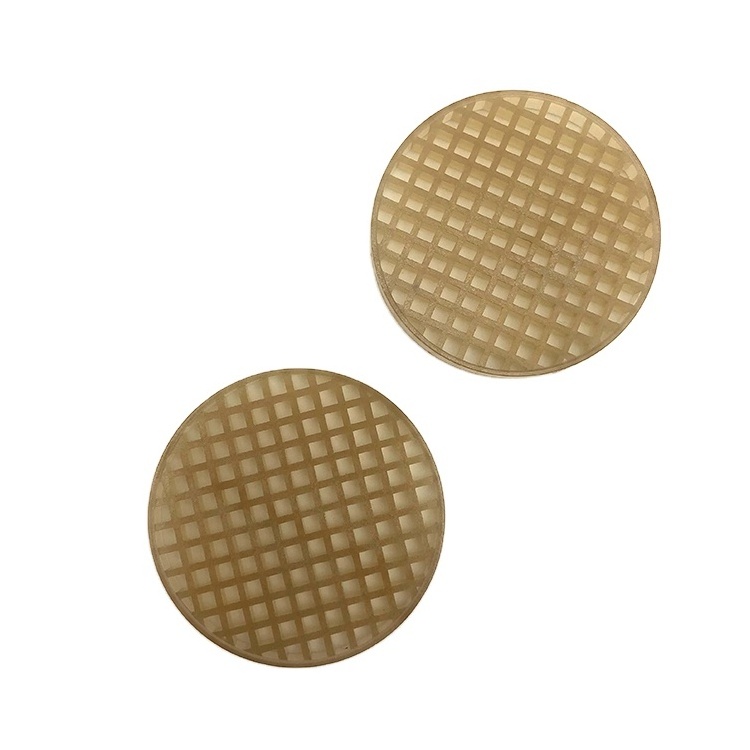

- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

HF001

-

Product name:

-

plastic

Quick Details

-

Processing Service:

-

Moulding, Cutting

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

HF

-

Model Number:

-

HF001

-

Product name:

-

plastic

Products Description

Hot Sale

Injection Mould

Product Desciption

1. Start from part design analysis. (Products drawings are needed, drawing in Stp./CAD/CAM,Solidworks,Pro/Engineer)

2. DFM reportwill be provided before mold making.If the design is not feasible, we will give some design modification proposes and seek approval from customers.If product is complex,moldflow report will be present as well.

3. Mold design can be provided to customer for checking if needed.

4.After everything confirmed, we will start to make mold. The mold status and plans will be updated to customers every week.

5.When molds are ready, we will make and provide same prototypes to customer for testing and confirmation.

6.After sample confirmed, the mold texture, mold NO. ,Index No. will be added on the mold, get ready for injection molding/ mass production.

7. Injection molding service is provided, we have more than 30 injection molding machine, from 80 ton to 1000 ton.

8..Besides,we also provide printing,welding,assembly and packing service.

2. DFM reportwill be provided before mold making.If the design is not feasible, we will give some design modification proposes and seek approval from customers.If product is complex,moldflow report will be present as well.

3. Mold design can be provided to customer for checking if needed.

4.After everything confirmed, we will start to make mold. The mold status and plans will be updated to customers every week.

5.When molds are ready, we will make and provide same prototypes to customer for testing and confirmation.

6.After sample confirmed, the mold texture, mold NO. ,Index No. will be added on the mold, get ready for injection molding/ mass production.

7. Injection molding service is provided, we have more than 30 injection molding machine, from 80 ton to 1000 ton.

8..Besides,we also provide printing,welding,assembly and packing service.

|

Mold Cavity

|

Single Cavity & Multi-Cavity&FamIly-cavities

|

|

|

|

||

|

Runner System

|

Hot Runner or Cold Runner

|

|

|

|

||

|

Advantage

|

Rich experience in high temperature mold for engineering plastic, such as PEEK, PVDF,PFA,PEI,PAI.

|

|

|

|

||

|

Mould Base

|

SD,LKM Standard, HASCO Standard Self-Made,etc.

|

|

|

|

||

|

Mould Material

|

PP P20/718H/738/NAK80/S136/H13

|

|

|

|

||

|

Surface treatment

|

Texture/Sandy/MT/YS/SPI/EDM finish/smooth/glossy/VDI

|

|

|

|

||

|

Gate Type

|

Pinpoint Gate, Edge Gate, Sub Gate,Film Gate,

|

|

|

|

||

|

|

Valve Gate,Open Gate, etc.

|

|

|

|

||

|

Plastic Material

|

PEEK/PPS/PPSU/PFA/PVDF/Teflon/PEI/PAI/PC+ABS/PBI/PES/PI

|

|

|

|

||

|

|

POM(Delrin)/PP/PE/PMMA(Acrylic)/PC//PA66/TPE/TPU/PBT/ABS

|

|

|

|

||

|

Delivery time

|

Normally it takes 20-40 days to make mold,actual time depends on the part design.

|

|

|

|

||

|

Mold life

|

200000 times~300000 times

|

|

|

|

||

|

Additional Service

|

We keep, maintain, repair the mold for free all the life, if the mold life is end, we will make a new mold by our cost.

|

|

|

|

||

|

Mold cost refund

|

If the product order amount meet 25 times of the mold cost, we will refund the mold fee.

|

|

|

|

||

Hot Searches