- Product Details

- {{item.text}}

Quick Details

-

Warranty:

-

1 years

-

Place of Origin:

-

Shanghai

-

Brand Name:

-

HAL-LOK

-

Model Number:

-

SKT-4

-

Withstand voltage:

-

0~25 MPa

-

Temperature resistance:

-

0~200℃

-

Diameter:

-

1/16" to 2"

-

Processing and customization:

-

Available

Quick Details

-

Technics:

-

Forged

-

Shape:

-

Equal

-

Head Code:

-

Hexagon

-

Warranty:

-

1 years

-

Place of Origin:

-

Shanghai

-

Brand Name:

-

HAL-LOK

-

Model Number:

-

SKT-4

-

Withstand voltage:

-

0~25 MPa

-

Temperature resistance:

-

0~200℃

-

Diameter:

-

1/16" to 2"

-

Processing and customization:

-

Available

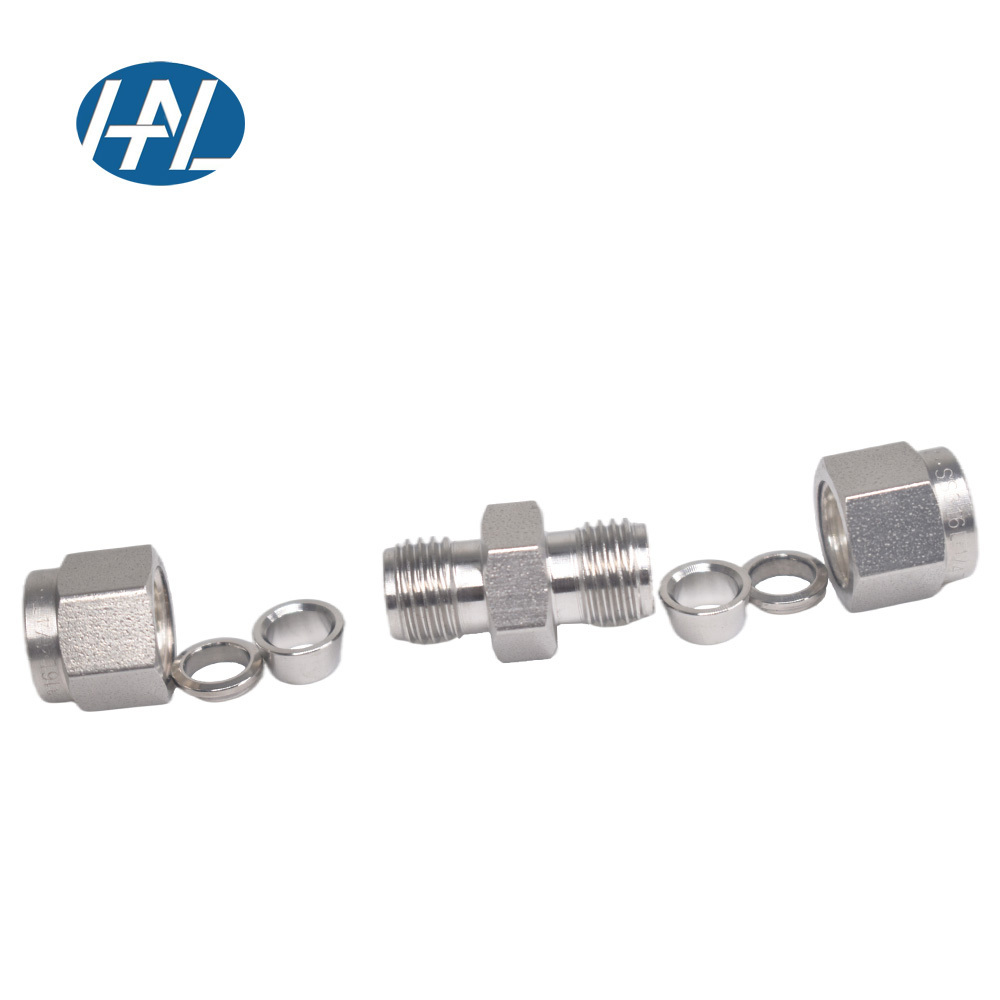

HAL-LOK Tube Fittings

|

Product Information

|

|

|

|

|

||||

|

Available materials:SS304 , SS316 , 904L , Alloy , etc.

|

|

|

|

|

||||

|

Available in size:1/16" to 1" and 3mm to 38mm

|

|

|

|

|

||||

|

Thread:NPT, BSP, BSPT, UNF, ISO, SAE etc.

|

|

|

|

|

||||

|

Working temperature:0~200℃

|

|

|

|

|

||||

|

Working pressure:1000psi to 3000psi

|

|

|

|

|

||||

|

Silver plated nuts, reduce torque and easy to install.

|

|

|

|

|

||||

|

Corrosion free with excellent chemical resistance

|

|

|

|

|

||||

|

Hardened threads with smooth surface finish avoid galling and help to extend the fitting service life.

|

|

|

|

|

||||

PRODUCT SPECIFICATIONS

Installation Instructions

Installation steps of ferrule:

Operating instructions for sealing connection: applicable to 1 / 4 to 1 in. Or 6 to 25 mm pipe diameter (as shown in Figure 1).

The sealing connection can be easily achieved by following three steps:

1. Put the connector nut in a loose state and insert it into the connecting pipe. Make sure that the connecting pipe is inserted into the bottom of the connector.

2. Pre tighten the nut manually.

3. Fix the connector body with corresponding tools, and tighten the nut with an appropriate wrench for 1 turn. After one full turn, continue to turn 1 / 4 turn.

Operating instructions for sealing connection: applicable to 1 / 8 in. Or 4mm pipe diameter. Follow the above steps. Tighten the nut for 3 / 4 turns from the pre tightening state (as shown in Figure 2),

be careful:

Please use high quality polishing tube. Check that the surface of the connecting part of the steel pipe shall not be scratched, and the pipe orifice shall be smooth and free of burr. Make sure that the steel pipe is inserted into the joint vertically. If bending pipe is needed, make sure that the straight part inserted into the interface is not less than 30mm.

Repeat the installation steps

1. Insert the tube with pre installed ferrule into the connector and tighten the nut with fingers

2.Tighten the nut to the last tightening position with a wrench

3. After reaching the position, use a wrench to tighten it slightly(normally, it depends on experience operation, if there is no experience, it can be rotated by 1 / 12 turn each time);

Recommended length of bend

When installing the connector near the bend of tube, enough length of straight tube must be ensured to make thetube contact the locating step of tube connector.

Hot Searches