- Product Details

- {{item.text}}

Quick Details

-

Power:

-

6-15kw

-

Dimension(L*W*H):

-

OEM

-

Product name:

-

Foundry Casting Producing Line

-

pulse strength KN:

-

80-200

-

recycle of crushing:

-

less2.5

-

strip ratio of demolding:

-

2.5%

-

Application:

-

Foundry Resin Sand Casting Equipment

-

Installation:

-

Engineer Guide

-

Factory Visit:

-

Welcomed Warmly

-

Advantage:

-

Convenient Operation

-

Capacity:

-

5-100t/h

-

Certification:

-

ISO9001-2000,BV,CE

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

BINHAI

-

Voltage:

-

280-480V

-

Power:

-

6-15kw

-

Dimension(L*W*H):

-

OEM

-

Product name:

-

Foundry Casting Producing Line

-

pulse strength KN:

-

80-200

-

recycle of crushing:

-

less2.5

-

strip ratio of demolding:

-

2.5%

-

Application:

-

Foundry Resin Sand Casting Equipment

-

Installation:

-

Engineer Guide

-

Factory Visit:

-

Welcomed Warmly

-

Advantage:

-

Convenient Operation

-

Capacity:

-

5-100t/h

-

Certification:

-

ISO9001-2000,BV,CE

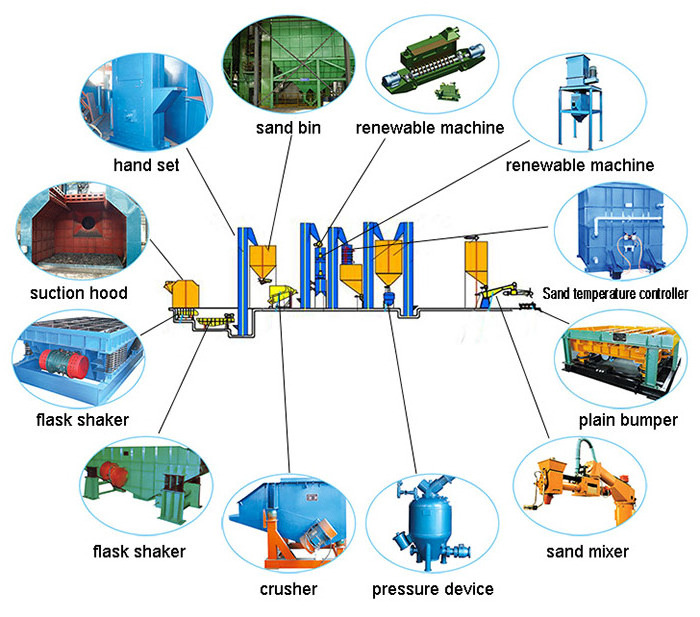

Casting Producing Line/Casting Machine for Foundry Industry

At present, we have produced 10t/h, 15t/h, 20t/h, 25t/h, 40t/h, 60t/h, 80t/h resin

sand production sand, 10t/h, 15t/h, 20t/h, 25t/h, 40t/h, 60t/h, 80t/h, 100t/h high speed

,medium speed, low speed different types of fixed type. Mobile sand mixer and all

kinds of fixed and mobile vibration platform, ejector rob draw pattern machine,

turn-over draw pattern machine and so on. During several years’ development and

progress, we not only optimize the design in the structure of equipment, such as

regenerating machine, sand mixer and so on, but also make a lot of breakthrough

in the selection of new materials. Our company undertakes all to the key projects

from shakeout, crushing, reclamation, adjusting the temperature, conveying and

molding.

1.Resin sand is a resin binder-type configuration(core)sand.

2.sand reclamation is to maximize the surface to remove sand binder film,adjust the

sand surface(particle size),it is very economic to use in place of new sand.

3.Sand reclamation and reuse, the new sand consumption can be saved as well as

throwing sand required for the old ,such as transportation costs, and renewable sources

of sand evenly, smooth surface ,good thermal stability, and therefore enhance the quality

of castings, especially in the old sand resin sand reclamation and reuse,thus can

reduce the amount of resin to reduce the cost of resin-bonded sand,but also to reduce

the emissions from environmental pollution caused by waste sand.

4.. we have produced 5t/h,10t/h, 15t/h, 20t/h, 25t/h, 40t/h, 60t/h, 80t/h resin sand

production sand, 10t/h, 15t/h, 20t/h, 25t/h, 40t/h, 60t/h, 80t/h, 100t/h high speed,

medium speed, low speed different types of fixed type

Composition

Main equipment Shakeout machine, Vibrating conveyor, Belt conveyor, Pneumatic

conveyor, Magnetic separator, Air seprator, Sand screening device, Bucket elevator,

Chain elevator, Crusher, Sand reclamation device, sand temperature adjustment

device, Cooler, Drying device, Electronic scale device, Continuous sand mixer,

Molding machine, Dust collector, Electronic control system, etc.

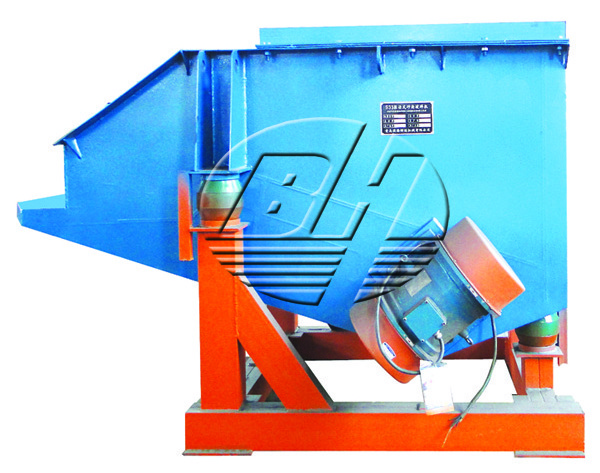

Crusher

S33 series sand crusher is the fourth-generation which development by our company.

It can crushing, screening, and preregeneration at the same time. More reliable, simple

structure and convenient maintenance.

S25 Double arm resin sand mixer

Mixing time short, no head or tail sand loss. The rotation of the double arms is flexible,

and operation area is large

All opening type sand mixing stirring cage wall, easy to clean and adjust the blade,

easy operation and simply maintenance

Reduce the charging quantity of cementing agent, improve the quality of molding

sand to get good economic efficiency

PLC control, protection, running stable and reliable, it realized the automatic production.

Resin sand product-line renewable machine

Use the rubbing against each other to tack off the film of old sand, change the performance

of old sand, to rebirth the sand again.

Why choose us?

1. Nearlly 30 years experience with 11 professional engineers

2. CE,BV,ISO certificate

3. one year warranty for machine and spare parts

4. considerate after-sale service and Technial Assistance and freecharge for installing ,debugging and training

5. world class shot blasting machine

6. OEM

7. Quick delivery/good quality/ competitive price

8. Binhai Jincheng is your Win-win partner

9.Free charges for installing,training and debugging.

Payment item

1.T/T,30% deposit, 70% before shipment

2.L/C irrevocable LC at sight

3.100% western union in advance

MOQ

1 SET

Delivery time

1.Depond on the machine, 30 days usually.

Qingdao Binhai Jincheng Foundry Machinery Co.,Ltd

have more than 30 year experience in foundry machine industry. We have 10 skillfull technical engineers and more than 100 experienced workers. Our products occupy 30% of China local market with good reputation.

Our company focus on design, research, develop and produce shot blasting machines,sand blasting rooms, sand processing equipments, environmental protection equipment, etc. Regarding of shot blasting machines, we have roller conveyor type, overhead chain type, hook type, tumble belt type, wire mesh type, road surface type, and some special big shot blasting equipment for cleaning the wire roll coil and stainless steel roll. All machines are professionally designed by our highly-experienced engineers with Auto CAD & Solidworks. OEM & ODM service is available .