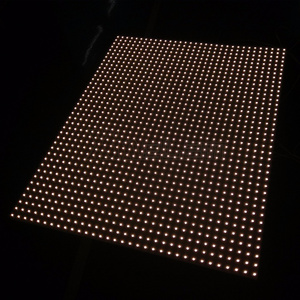

Use advanced laser-dot technology to

produce high-definition surface light illumination.

- Product Details

- {{item.text}}

Quick Details

-

Warranty(Year):

-

2-Year

-

Color Temperature(CCT):

-

3000-6500K

-

Support Dimmer:

-

Remote Control/ App control

-

Input Voltage(V):

-

12/24V

-

Lamp Luminous Flux(lm):

-

6000

-

CRI (Ra>):

-

80

-

Working Temperature(℃):

-

-20 - 65

-

Working Lifetime(Hour):

-

50000

-

Place of Origin:

-

CHN

-

Brand Name:

-

JMW

Quick Details

-

Lamp Luminous Efficiency(lm/w):

-

80

-

Application:

-

Indoor, Hotel Office Building Hospital

-

Lamp Body Material:

-

Aluminum, Acrylic

-

Warranty(Year):

-

2-Year

-

Color Temperature(CCT):

-

3000-6500K

-

Support Dimmer:

-

Remote Control/ App control

-

Input Voltage(V):

-

12/24V

-

Lamp Luminous Flux(lm):

-

6000

-

CRI (Ra>):

-

80

-

Working Temperature(℃):

-

-20 - 65

-

Working Lifetime(Hour):

-

50000

-

Place of Origin:

-

CHN

-

Brand Name:

-

JMW

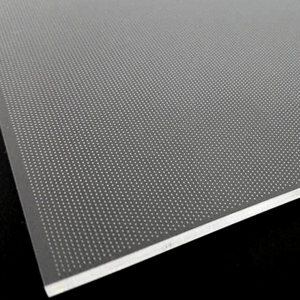

Specification of Acrylic LGP

|

Product name

|

Edgelit Light Guide Panel for onyx marble stone

|

|

Material

|

PMMA Acrylic

|

|

Density

|

1.2g/cm3

|

|

Standard size

|

any customized sizes

|

|

Thickness

|

2mm ,3mm, 4mm, 6mm,8mm ,10mm, 12mm, 15mm

|

|

Color and craft

|

clear+laser dotted/clear+3d V-cutting/clear+tiny stripes

|

|

Packing

|

covered with PE film, and using cartons or wooden pallet (case)for delivery

|

|

Certificate

|

SGS, ISO9001, CE

|

|

MOQ

|

1pcs(negotiable when we have in stock)

|

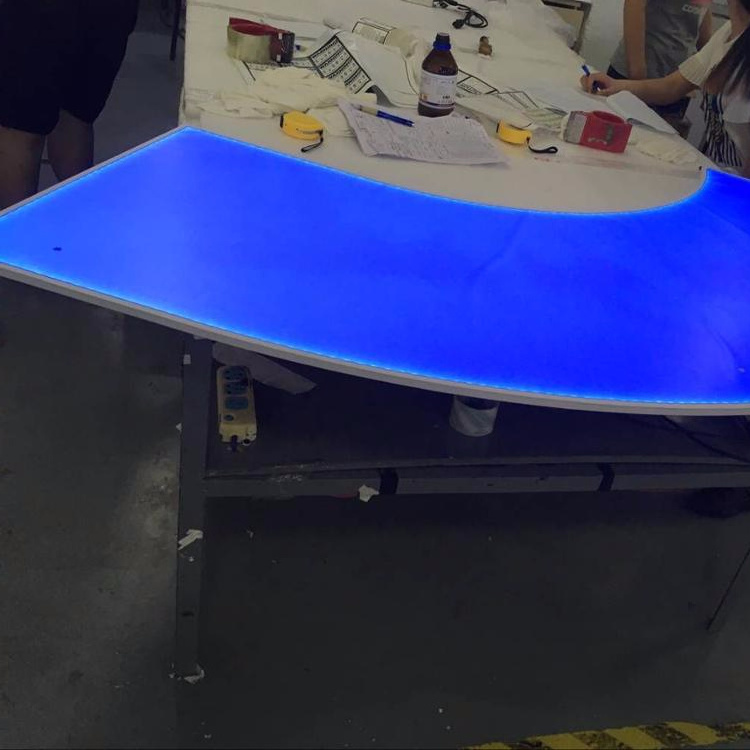

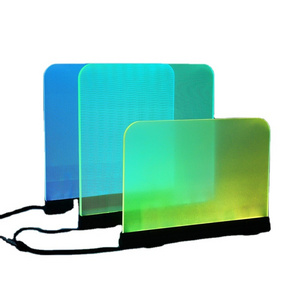

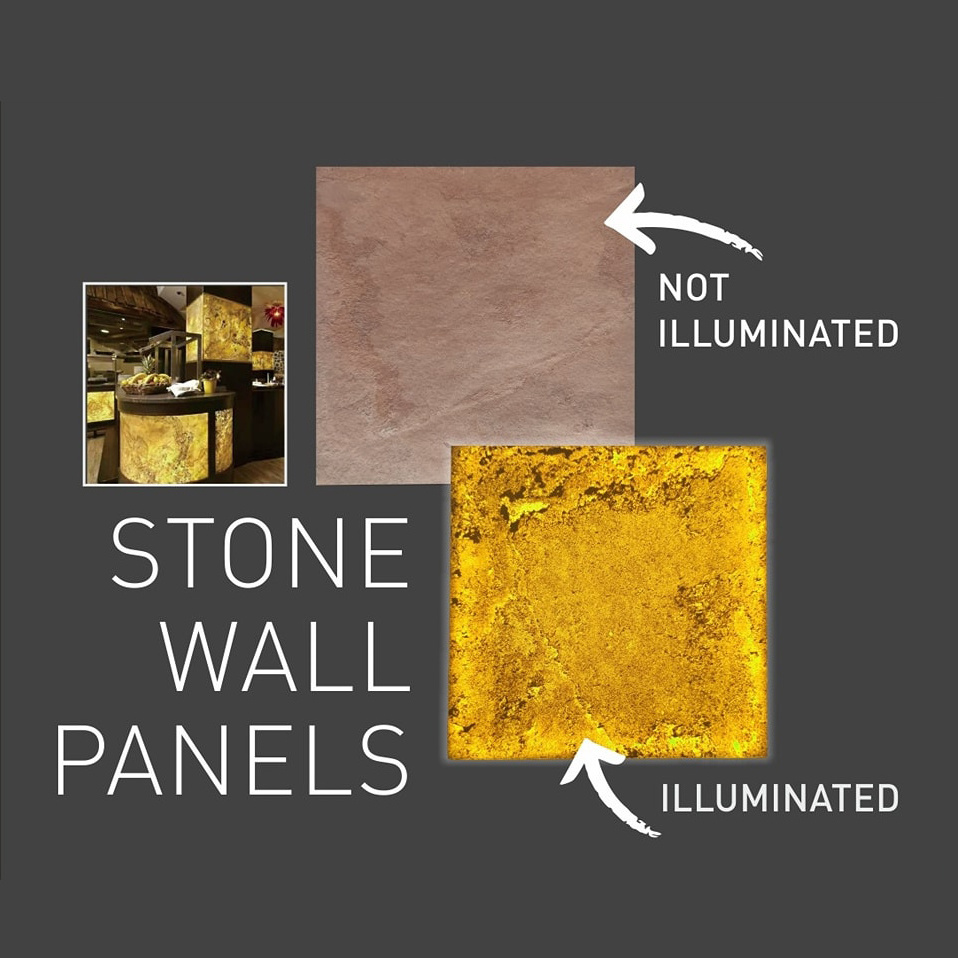

Product Description

Left:

The effect of turning on the backlight

Right:

The effect of not turning on the light

Key Features

* 90Lm/w and 95% light uniformity.

* high-quality PMMA raw material.

* high-definition lighting

* Weatherproof

* Double-side lighting available

* any shape or size for specific needs.

* Longer lifespan up to 100,000 hours.

* Low power consumption

* various industrial application

such as backlight display, refrigerator lighting, light boxes, elevator lighting,

and display rack lighting.

Laser dotted:

V-cutting:

Cases

The step to make your idea come true.

1.

Ideas of a new project

2.

Provide high standard solutions with competitive price

3.

Make a prototype to match

4.

Production for each customized specific project against the approval prototype

Packing & Delivery

About Us

JMW IS THE PERFECT CHOICE FOR YOUR BUSINESS BACKLIGHTING NEEDS.

Since 2014, JMW began adopting the edge lit lighting technologies for backlighting translucent materials for many project including cosmetic showcase display, bar counter lighting resource, direction sign led light panel, shop display illumination and other backlit panel lighting etc. JMW is dedicated to supply high quality LED panel light to meet with different project solution and the needs of the architectural lighting industry. Since we launch workshop, our LED Light Sheet has been used around the world by lighting designers and architects. We are proud that our led light panel quality and fast service are recognized by our clients.

FAQ

Q1: The process of complete an order?

Q3: Does diffuser have direction?

Q4: Which Storage environment is recommended?

Q2: How long does it take for order preparation?

A2: 1~2 weeks (in stock)/ 3~4 weeks (without stock)

Q3: How do you pack the sheets?

A3: Process as below

1.Place corrugated paper on top of the pallet

2.Cover and surround goods with PE films after stacking mother sheets

3.Use angle boards around the edges of the goods (if size under 600x600mm)

4.Use wrapping tape to fix goods on pallet

A1: u

nderstanding of what your lighting project

>> C

reate a detailed product design report(carefully considering the design, performance and budget) >>

Sample Design >>

After confirming the sample, mass production and shipping

Q2: What should I do before assembling?

A2: -tear the protection film out

-clean the sheets with an air gun

-wear gloves (especially for LGP)

-clean the sheets with an air gun

-wear gloves (especially for LGP)

Q3: Does diffuser have direction?

A3: The pattern must be outside

Q4: Which Storage environment is recommended?

A4: -Dry

-Avoid moisture & direct sunlight

-A black cover on pallet is also an option

-Avoid moisture & direct sunlight

-A black cover on pallet is also an option

Q5: Which way can I choose for shipping?

A5: by Air, Sea & Train

Q2: How long does it take for order preparation?

A2: 1~2 weeks (in stock)/ 3~4 weeks (without stock)

Q3: How do you pack the sheets?

A3: Process as below

1.Place corrugated paper on top of the pallet

2.Cover and surround goods with PE films after stacking mother sheets

3.Use angle boards around the edges of the goods (if size under 600x600mm)

4.Use wrapping tape to fix goods on pallet

Hot Searches