- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

SONGHU

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

15000*1500*2300 mm

-

Power (kW):

-

40

-

Weight:

-

2300 KG

-

Machine Type:

-

Filament Production Line

-

Raw Material:

-

ABS PLA PETG etc

-

Certification:

-

CE

-

Water Tank:

-

Stainless steel SUS304

-

Storage Device:

-

8 meter

-

Extrusion Mould Material:

-

S136

-

Motor:

-

Siemens

-

Filament Diameter:

-

1.75 mm / 3.0 mm

-

Tolerance:

-

±0.02 mm

-

Inverter:

-

Delta

Quick Details

-

Screw Design:

-

Single-screw

-

Screw L/D Ratio:

-

28:1

-

Screw Speed (rpm):

-

1420 rpm

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

SONGHU

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

15000*1500*2300 mm

-

Power (kW):

-

40

-

Weight:

-

2300 KG

-

Machine Type:

-

Filament Production Line

-

Raw Material:

-

ABS PLA PETG etc

-

Certification:

-

CE

-

Water Tank:

-

Stainless steel SUS304

-

Storage Device:

-

8 meter

-

Extrusion Mould Material:

-

S136

-

Motor:

-

Siemens

-

Filament Diameter:

-

1.75 mm / 3.0 mm

-

Tolerance:

-

±0.02 mm

-

Inverter:

-

Delta

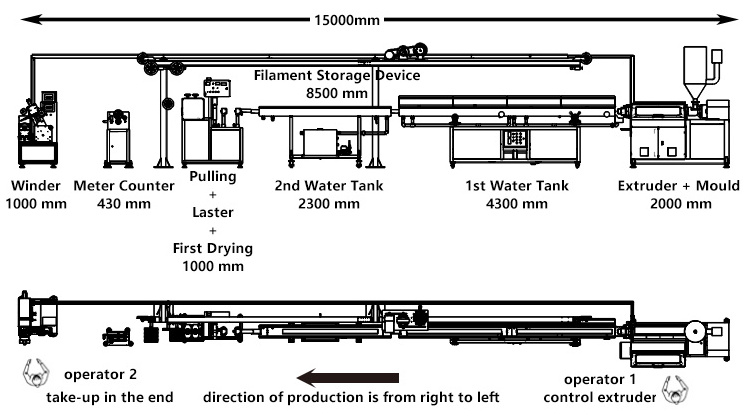

Product Introduction

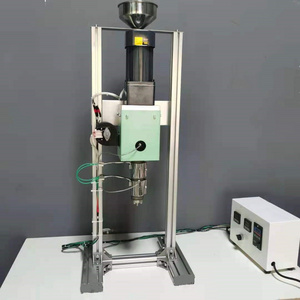

Single Screw Extruder / 3D Filament Extruder Machine / Plastic Filament Extrusion Machinery

Songh 3D printer filament production line integrates precision extrusion and automated winding system, which ensures

neat winding and

consistent filament diameter. It is suitable for making ABS, PLA, PETG, PC, PA and other materials.

Machine Parameters

|

Model

|

SHSJ-45

|

SHSJ-35

|

SHSJ-25

|

|

Capacity (kg/h)

|

15-20

|

8-12

|

1-2

|

|

Screw Diameter

|

45 mm

|

35 mm

|

25 mm

|

|

Screw L/D

|

28:1

|

28:1

|

25:1

|

|

Installed Power

|

40

|

30

|

7

|

|

Filament Diameter (mm)

|

φ1.75 / φ2.85 / φ3.0

|

φ1.75 / φ2.85 / φ3.0

|

φ1.75 / φ2.85 / φ3.0

|

|

Tolerance (mm)

|

φ0.02

|

0.02

|

0.03

|

|

L*W*H (mm)

|

15000*1500*2300

|

15000*1500*2300

|

4000*800*1500

|

|

Weight (kg)

|

2300

|

2100

|

500

|

Machine List

|

Number

|

Equipment Name

|

Quantity

|

Remark

|

|

1

|

SHSJ-45 Main Extruder

|

1 SET

|

45 mm screw diameter

|

|

2

|

Extrusion Mould

|

1 SET

|

S316

|

|

3

|

Heating Water Tank

|

1 SET

|

304 stainless steel

|

|

4

|

Cooling Water Tank

|

1 SET

|

304 stainless steel

|

|

5

|

Drying Device

|

1 SET

|

air blow

|

|

6

|

Storage Device

|

1 SET

|

tension control

|

|

7

|

Laser Diameter Gauge

|

1 SET

|

laser measure

|

|

8

|

Haul-Off Machine

|

1 SET

|

four wheel traction

|

|

9

|

Meter Counter

|

1 SET

|

automatic metering

|

|

10

|

Winder

|

1 SET

|

neat winding

|

Machine Details

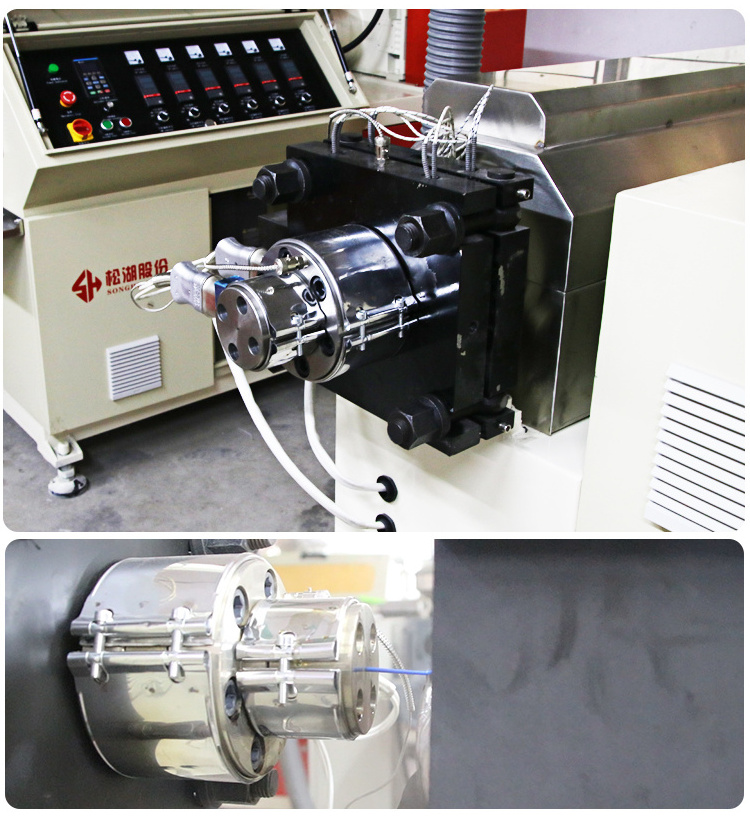

SHSJ-45 Main Extruder

Advanced extruders capable of melting and mixing various raw materials efficiently.

High-precision temperature and extrusion control systems to maintain optimal processing conditions, ensuring consistent filament diameter.

---Screw: 45mm diameter, screw L/D: 28:1, 38CrMoAlA

material

---Barrel: 38CrMoAlA material, nitriding and polishing finish

---Heating Zone: 4 heating zones for screw, 1 heating zone for flange, 1 heating zone for mould

---Driving Motor: DELTA AC servo motor, 11 kw power

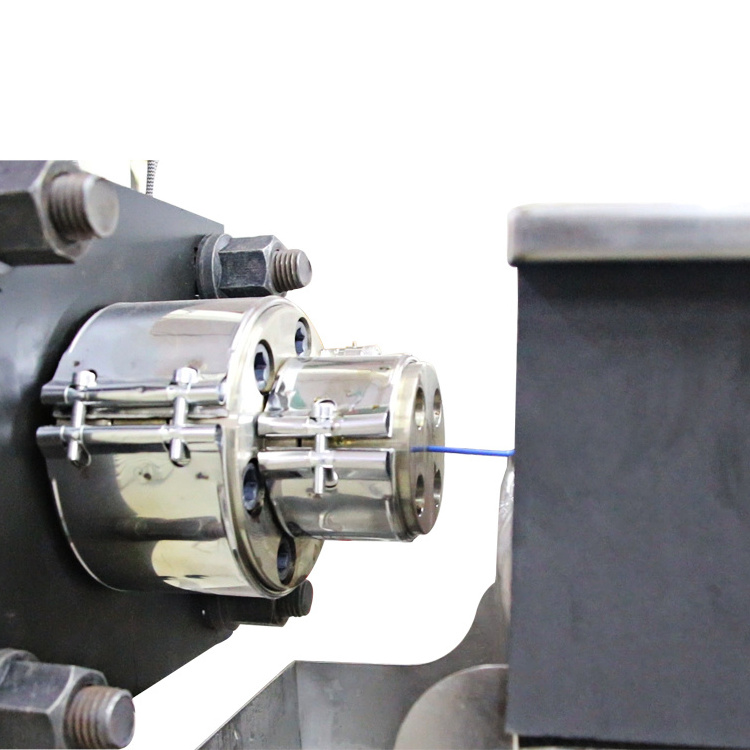

Extrusion Mould

After the plastic is melted and mixed, it is forced through a die that shapes it into filament diameter (1.75mm or 2.85mm or 3.0mm).

Forged with S136 material and special shunt pressurization structure, it is more conducive to the stable extrusion of filaments.

Water Tank

This section includes a heating tank and cooling tank to gradually cool down the extruded filament and solidify it.

The heating water tank acts as a buffer between the hot extruded filament and the subsequent cooling stages, preventing sudden temperature changes and allowing for gradual cooling. The cooling water tank follows the heat water tank.

Material: 304 stainless steel

Heating power: 2 KW

Heating water tank length: 6 meters

Cooling water tank length: 4 meters

Three directions adjustment: f

ront and back, left and right, up and down

Filament Storage Device

It can store up to 100 meters filament. Its function is to avoid the pollution caused by the falling of filaments to the ground due to too fast production speed during the replacement of filament spool.

Tension control mechanisms ensure that the filament is wound onto the pulley with consistent tension, preventing over-tightening or slack winding, which can lead to filament breakage or deformation.

Laser Diameter Gauge

Continuously monitor filament diameter to meet specifications.

It will trigger alarms if measurements exceed specified tolerances.

Haul-Off Machine

Pull the filament at a controlled speed.

It is synchronized with the extruder's speed to ensure a consistent and even pull.

Meter Counter

The meter counter provides continuous and real-time length measurement as the filament is extruded and pulled through the production line. This ensures that each spool contains the correct amount of filament.

Winder

Automated winding systems for neatly winding filament onto spools.

The winding speed is adjustable to accommodate different filament production speeds.

Final Product

After-Sale Service

1.Technical Support

: Prompt and knowledgeable technical support to assist customers with troubleshooting, maintenance, and operational questions related to machines.

2.Warranty Coverage

: We offer one year warranty period, ensuring customers have confidence in the reliability of our equipment.

3.Spare Parts Availability

: We have readily available inventory of spare parts and accessories for extruder machine.

Our Company

Dongguan Songhu Plastic Machinery Co., Ltd (Stock Code: 834005) was established in 2010. The company's head-quarter is located in Dongguan city, Guangdong province of China, and covering an area of more than 10,000 square meters. SONGHU company own 100 employees with some of them have been working in the field for over 20 years experiences.

Songhu focuses on the R&D, production and sales of 3D printer filament extrusion line, plastic tube extrusion line and medical tubing extrusion line.

We are committed to providing customers with first-class extruder machine and extrusion application solutions.

Our advantages:

1.Rich industry resources:

Songhu has rich industry resources, and can provide you with raw material selection, mold design and manufacturing, extrusion equipment design and manufacturing, and other industry-related consulting, suggestions, and other supporting services.

2.Rich experience in extrusion equipment design and manufacturing:

After more than ten years of technological innovation and industry precipitation, we have mastered advanced extrusion equipment design and manufacturing processes, and enjoy a high reputation in the industry.

3.Perfect after-sales service:

Songhu has always attached importance to customer experience, we have a strong after-sales team, including after-sales customer service, after-sales engineers. We can quickly and efficiently solve all kinds of problems you may encounter during the use of equipment.

Our Customers

Contact us

Hot Searches