Brand:

Brand

Original: China

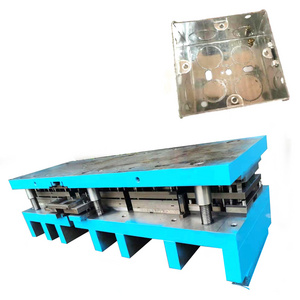

Aiming at the arrival of hi-tech industry, it is controlled by computer closed-circuit feed back system, so that the precision can maintain within 0.03mm.