Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Screw Speed (rpm):

-

37 rpm

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

LIANSHUN

-

Voltage:

-

380V 50HZ 3Phase(Customized)

-

Dimension(L*W*H):

-

22mx2.2mx3.2m

-

Power (kW):

-

55

-

Weight:

-

80000 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Name:

-

PVC WPC door board making machine

-

Raw material:

-

UPVC Powder

-

Product:

-

UPVC door window product

-

Motor:

-

SIEMENS Brand

-

Inverter:

-

ABB Brand

-

Temperature controller:

-

Japan Omron

-

Machine control:

-

PLC

-

Experience:

-

with over 10 years experience

-

Material:

-

Stainless Steel 304

Quick Details

-

Screw Design:

-

Double-screw

-

Screw L/D Ratio:

-

22:1

-

Screw diameter (mm):

-

65/132 mm

-

Screw Speed (rpm):

-

37 rpm

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

LIANSHUN

-

Voltage:

-

380V 50HZ 3Phase(Customized)

-

Dimension(L*W*H):

-

22mx2.2mx3.2m

-

Power (kW):

-

55

-

Weight:

-

80000 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Name:

-

PVC WPC door board making machine

-

Raw material:

-

UPVC Powder

-

Product:

-

UPVC door window product

-

Motor:

-

SIEMENS Brand

-

Inverter:

-

ABB Brand

-

Temperature controller:

-

Japan Omron

-

Machine control:

-

PLC

-

Experience:

-

with over 10 years experience

-

Material:

-

Stainless Steel 304

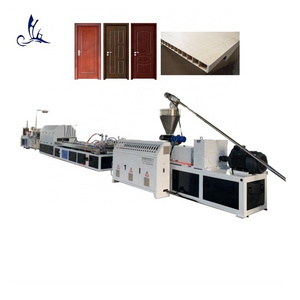

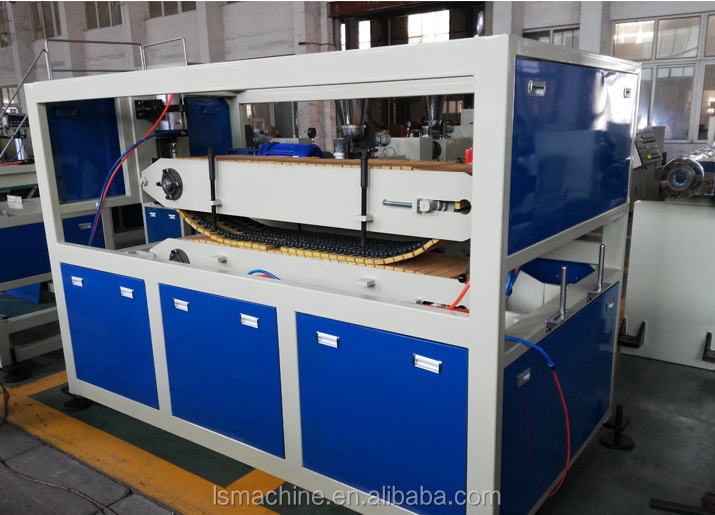

Jiangsu Plastic Extrusion Machinery PVC WPC Wood Plastic Composite Door Board Making Machine

Features of PVC WPC door board making machine:

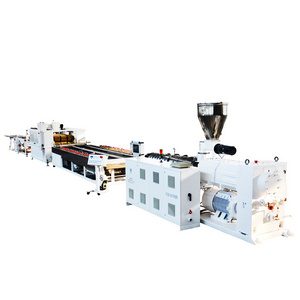

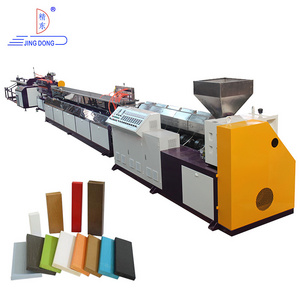

The PVC wide door extrusion production line of LIANSHUN adopts the latest manufacturing technology. It uses some parts of international famous brand.The SJSZ80/156,92/188 conical twin-screw plastic extruder are specially designed. Because it use ABB, SIEMENS frequency converter, RKC, and OMRON temperature control meter, it has the advantages of convenient and reliable operation etc. The PVC wood door extrusion production line is made up of conical twin-screw plastic extruder, broad mould, calibrator, cooling platform, crawler tractor, transverse cutting machine, and unload frame.

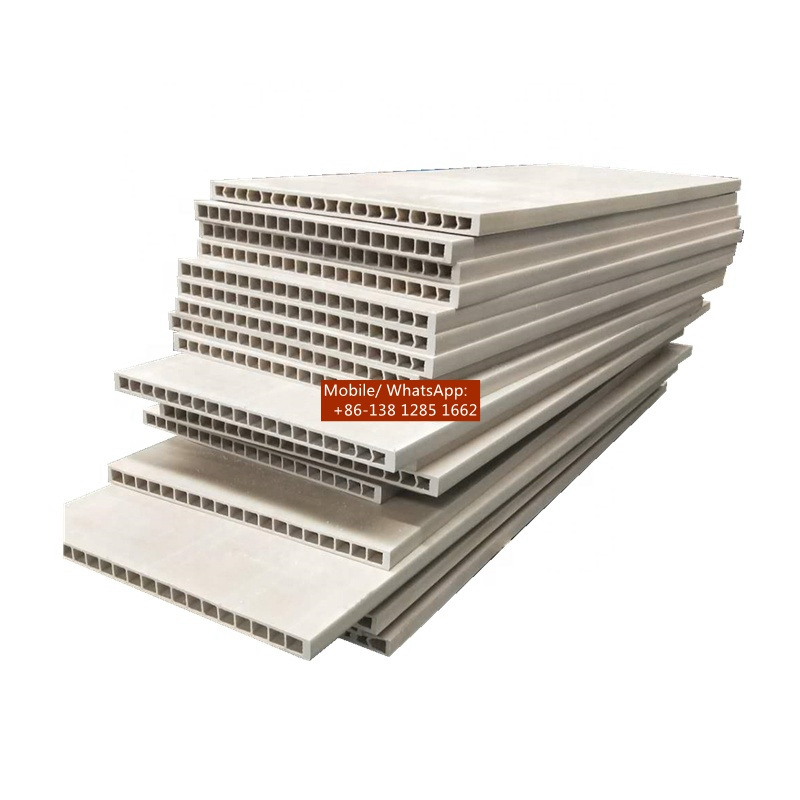

It can be used for inside and outside door, wall,window board etc. The raw material is PVC or PVC and wood mixing extrusion foaming process.The products of the PVC wide door extrusion production line have the advantages of wood and plastic. It has a unique appearance and overcomes the shortcomings of natural wood,but also has the good processing performance similar to that of wood.

The specific gravity can be controlled between 0.6-0.9kg/m3. It can be sawed, nailed, planed. The job can be completed by woodworking tools. Wood plastic materials and its products have the advantages of resistance to strong acid and alkali, water resistance, corrosion resistance, not easy to be eaten, anti aging, anti static, flame retardant.

Product features:

1.Working performance: energy saving 30-40%, stable operation, high production efficiency, low cost, high quality end products.

2.Ability to upgrade: easily upgrade, do not destroy the original structure, can change the extruder, and other parts, etc.

3.Maintenance conditions: provide maintenance accessories, provide training services.

4.Long working life

Main Technical Parameter:

|

Model

|

YF-600

|

YF-800

|

YF-1000

|

YF-1250

|

|

Max.width(mm)

|

600

|

800

|

1000

|

1250

|

|

Extruder model

|

SJSZ

80/156

|

SJSZ

80/156

|

SJSZ

92/188

|

SJSZ

92/188

|

|

Main motor power(kw)

|

55

|

55

|

132

|

132

|

|

Capacity (kg/h)

|

250-330

|

250-330

|

580-660

|

580-660

|

|

Cooling water (m³/h)

|

10

|

12

|

15

|

18

|

|

Compressed air (m³/min)

|

0.6

|

0.8

|

1.0

|

1.2

|

Composition List:

|

Item

|

Quantity

|

|

SJSZ-XX conical twin-screw extruder and automatic feeding system

|

One set

|

|

Die mold and stock mold

|

One set

|

|

Vacuum calibration table

|

One set

|

|

Haul-off unit and cutting unit

|

One set

|

|

Stacker

|

One set

|

|

Electric control cabinet

|

One set

|

Final Products:

1. Turn key project

2. Technical documents

We will offer you all necessary documents, e.g. general layout plan, water scheme, electrical diagram and user manual after the contract is executed.

3.Arrangement for inspection, installation and testing work

We will inspect and test the machine in our factory first before shipping the machine. Customers are welcome to come and check the working machine, until the machine produces the exact products as customers requirements, and learn operation in our factory.

After the machine is delivered to customer’s factory, we will send one or two technicians to customer’s factory for on-site installation and commissioning of the whole machine line. Meanwhile, technicians will give free training lessons to workers in customer’s factory.

4.The guarantee period of the whole machine is 15 months.

5.Technical support from our factory is free of charge for all the life; quick response to any questions from customers.

1.Q: Are you an industry manufacture factory or a foreign trade company?

A: We are an industrial manufacture factory of plastic extrusion machinery and auxiliary equipment, which locates in Zhangjiagang city, China.

2.Q: Payment term:

A: Loading Port: Shanghai by sea or by train.

T/T, L/C, West Union, or Cash, etc.

3.Q: Do you have any other services for your products?

A: We have rich experience in manufacturing plastic machinery, so we can manufacture various machines according to customers’ requirement.

4. Q:How do you make the quotation for clients?

A:The price depends on quality and performance but the clients should be satisfied first.

Jiangsu Lianshun Machinery CO.,Ltd. is located in Zhangjiagang city, Jiangsu province, China. It’s a professional manufacturer specializing in research&development and producing plastic extrusion machinery. The main products include: plastic pipe extrusion lines, plastic profile production lines, plastic sheet extrusion lines, WPC board and profile extrusion line, PET bottle flakes washing recycling lines, PP/PE film washing recycling lines, PVC/PP/ PE pelletizing

lines and auxiliary machinery (mixer unit, crusher and shredder, belling machine, etc.)

We have enjoyed great prestige from our customers both at home and abroad with good products quality and considerate service.We exported our products to many countries and regions all over the world, such as the Mid-East, Africa, Southeast Asia, South America, Europe,etc.

We sincerely hope to cooperate with customers from all over the world.

If you are interested in PVC WPC door board making machine, please feel free to contact us, thanks!

Welcome you to China and Visit our factory, Running machine can be showed anytime!