- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Sino-Tech

-

Application:

-

PET bottle plastic recycling

-

Production Capacity (kg/h):

-

500 - 3000

-

Voltage:

-

380V or customization

-

Dimension(L*W*H):

-

50*10*5

-

Power (kW):

-

300

-

Weight (T):

-

25

-

Material Process:

-

PET bottle plastic

-

Function:

-

crushing, washing, recycling

-

Color:

-

Green or customization

-

Belong:

-

plastic recycling machine

-

Electric component:

-

Siemens, Omron, ETC

-

Machine type:

-

recycle washing line

-

Production Capacity:

-

100%

-

Material:

-

HQ 304 stainless steel

-

Keywords:

-

PET bottle plastic recycling

-

Type:

-

Recycling machine

Quick Details

-

Machine Type:

-

PET Bottle Washing Line

-

Max.Production Capacity (kg/h):

-

3000

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Sino-Tech

-

Application:

-

PET bottle plastic recycling

-

Production Capacity (kg/h):

-

500 - 3000

-

Voltage:

-

380V or customization

-

Dimension(L*W*H):

-

50*10*5

-

Power (kW):

-

300

-

Weight (T):

-

25

-

Material Process:

-

PET bottle plastic

-

Function:

-

crushing, washing, recycling

-

Color:

-

Green or customization

-

Belong:

-

plastic recycling machine

-

Electric component:

-

Siemens, Omron, ETC

-

Machine type:

-

recycle washing line

-

Production Capacity:

-

100%

-

Material:

-

HQ 304 stainless steel

-

Keywords:

-

PET bottle plastic recycling

-

Type:

-

Recycling machine

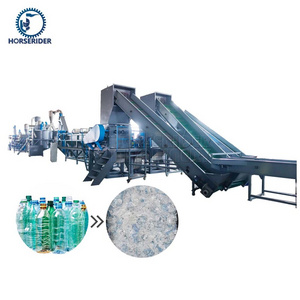

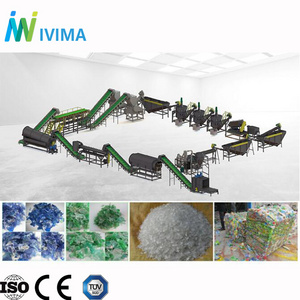

Plastic Recycling Washing Line

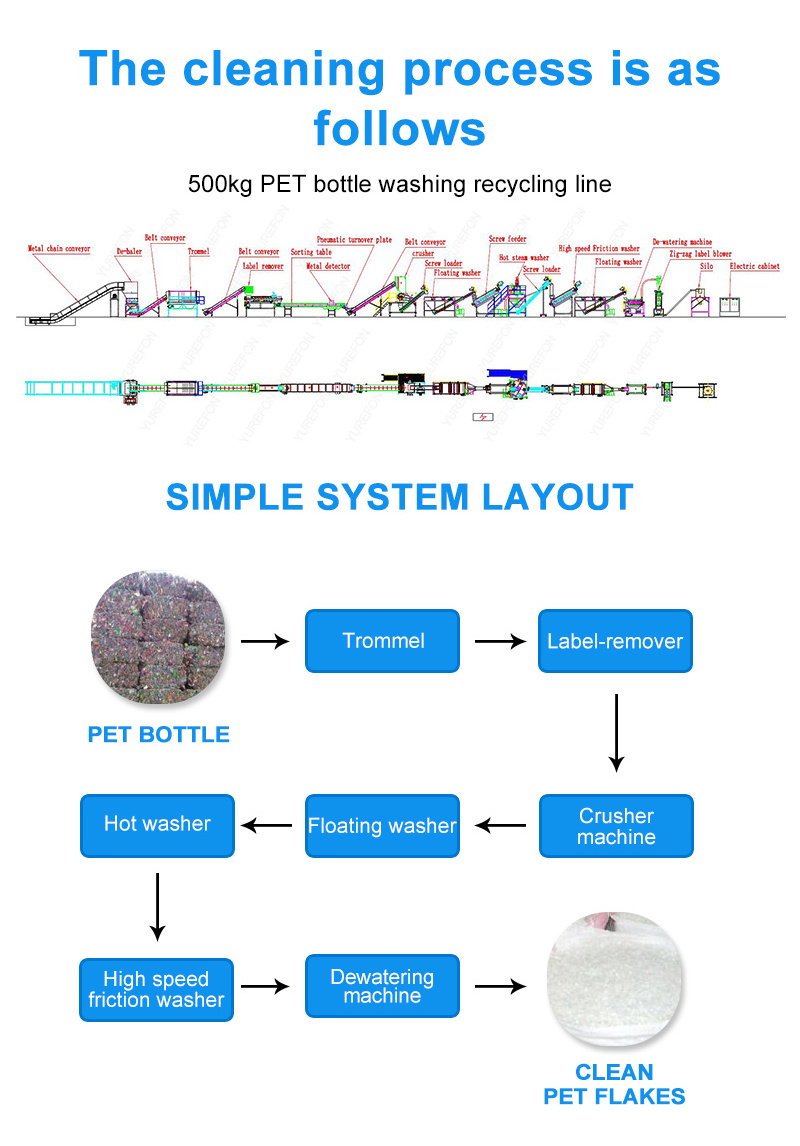

PET bottle washing recycling line is a full automatic crushing washing dewatering and drying production line, it is the ideal equipment to waste mineral water bottles, cola bottle, PET bottle sorting, label removing, crushing, washing, dewatering and drying machines.

The features of this line: beautiful appearance, high capacity and practical and reliable. The equipment can wash ABS, PVC sink plastic too. The whole production line has a high-degree automation, only need 3-5 operators, the capacity is: 500, 1000, 1500, 2000, 3000kg/h (also can be customized), the water rate of flakes less than 2% at the same time.

The production line includes: De-baler, belt conveyor, trommel, label remover, sorting table, crusher, floating washing tank, screw feeder, hot washer, high speed friction washing machine, centrifugal dewatering machine, dryer blower and label seperator, silo, electric cabinet etc.

Product Description:

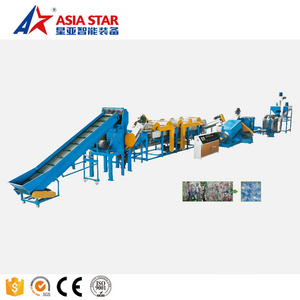

1.This line is mainly used for recycling the waste PET bottle, PET container etc.

2. To separate PET bottles to flakes from label, cap, oil, garbage.

3. This line is composed of separator, crusher, cold & hot washing system, dewatering, drying, packing system, etc.

4. Easy to operate, Full automatic.

5. Production capacity: 500KG/H, 1000KG/H, 1500KG/H, 2000KG/H, 3000KG/H

Main Advantage:

1. Automotive line for recycling the PET bottles and other waste plastic profile, except the film.

2. The final product is the cleaning flakes, if you want the final product is pellets, we should equip the granulator line again.

Features:

Capacity: 500—3000kg per hour

Moisture of PET Flakes: Less Than 2%

Cap &Label separate with the PET bottle flakes automatically

Bottle Types: PET Bottle, Plastic Bucket, Water Bottle, Coke Bottle,

Application: PET Strap, PET Yarn Fiber, PET Sheet

Parameters

|

Model

|

PET-500

|

PET-1000

|

PET-1500

|

PET-2000

|

PET-3000

|

||||

|

Capacity

|

500kg/h

|

1000kg/h

|

1500kg/h

|

2000kg/h

|

3000kg/h

|

||||

|

Total power

|

180kw

|

240kw

|

350kw

|

440kw

|

653kw

|

||||

|

Actual power

|

126kw

|

168kw

|

245kw

|

308kw

|

457kw

|

||||

|

Workers

|

5-6persons

|

7-8persons

|

9-10persons

|

11-12persons

|

14-15persons

|

||||

|

Water needed

|

3-5t/h

|

5-6t/h

|

6-8t/h

|

6-8t/h

|

7-10t/h

|

||||

|

Final production

|

Water content: ≤1.5%

Stacking density: 0.25-0.35 g/m³ Flakes size: 14mm (according to customer request) Fine granule: ≤ 3%; Powder: ≤ 5% |

|

|

|

|

||||

MACHINE DETAIL

01 Metal chain conveyor

Usage: Cut the bundled PET bottles of wire, through the chain conveyor to the unpacking machine unpacking.

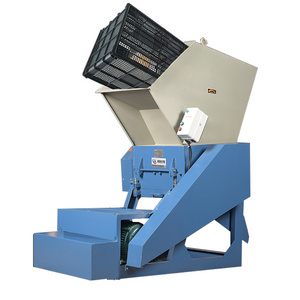

02 De-baler

Usage: Manully cut off the packaging steel line of the packaged bottles. then put them into the debaler. The packaged bottles will opened by the running screw blade and run ahead to exit.

Usage: Separate different impurities such as sand, rocks ,metals, caps according to different size of the holes.

04 Label-remover

Usage: for removing the labels by friction between screen and arms

.

Usage: Manually separate any impurities that can be seen.

06 Wet crusher

Usage: to crush PET bottles into PET flakes.

Usage: to remove labels, caps chemicals dirties etc.

08 Hot washer

Usage: for wash with hot water and detergent to get rid of oil, dirties and some labels.

09 High speed friction washing machine

Usage: through the injection of high pressure water, the effective remova of chemicals and impurities.

10 Centrifugal dewatering machine

Usage: for reducing water content.

Usage: to separate labels and dust from the flakes.

Hot Searches