- Product Details

- {{item.text}}

Quick Details

-

Size:

-

Different As Each Model

-

Power:

-

Can customized

-

Productivity:

-

45-2350m3/h

-

Weight (KG):

-

150 kg

-

Self-cleaning time:

-

10-60s

-

Self-cleaning control mode:

-

Differential pressure, time and manual

-

Electronic control method:

-

220V50Hz

-

Control interface:

-

Digital display, knob, switch

-

Filter type:

-

304 wedge net

-

Work pressure:

-

0.1-2.5Mpa

-

Working water temperature:

-

95°C

-

Filter precision range:

-

100-3000um

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Beite

-

Weight:

-

Different As Each Model

-

Size:

-

Different As Each Model

-

Power:

-

Can customized

-

Productivity:

-

45-2350m3/h

-

Weight (KG):

-

150 kg

-

Self-cleaning time:

-

10-60s

-

Self-cleaning control mode:

-

Differential pressure, time and manual

-

Electronic control method:

-

220V50Hz

-

Control interface:

-

Digital display, knob, switch

-

Filter type:

-

304 wedge net

-

Work pressure:

-

0.1-2.5Mpa

-

Working water temperature:

-

95°C

-

Filter precision range:

-

100-3000um

Product Description

Shape Parameters

|

Self-cleaning time

|

10-60s

|

|

|

|

|||

|

Self-cleaning control mode

|

Differential pressure, time and manual

|

|

|

|

|||

|

Electronic control method

|

220V50Hz

|

|

|

|

|||

|

Control interface

|

Digital display, knob, switch

|

|

|

|

|||

|

Filter type

|

304 wedge net

|

|

|

|

|||

|

The amount of water treated by a single unit

|

45-2350m3/h

|

|

|

|

|||

|

Work pressure

|

0.1-2.5Mpa

|

|

|

|

|||

|

Working water temperature

|

95°C

|

|

|

|

|||

|

Filter precision range

|

100-3000um

|

|

|

|

|||

|

The amount of water required for self-cleaning

|

<1%

|

|

|

|

|||

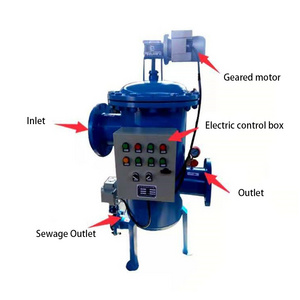

When the filter is working, the water flow guide valve is open, the water flow enters the filter from the inlet, and flows into the outlet after being filtered by the filter screen. The machine adopts differential pressure control and positioning control to automatically clean the filter screen. When the differential pressure between the inlet and outlet of the filter reaches the set value or the timer reaches the preset time, the electric control box will send a signal, the drain valve will be opened, the water flow guide valve will be closed, and the impurities stuck on the inner wall of the filter screen will be washed further by the water flow. When the water flow guide valve is fully closed, the water flow is forced to enter the outside of the filter screen from the mesh in the inlet section of the filter, most of the clean liquid flows out from the outlet, and part of the clean liquid enters the inside of the filter screen from the outside of the filter screen (because the system It will be in a pressure relief state, and the internal pressure of the filter screen is lower than the external pressure), so as to backwash the filter screen. The special structure of the stainless steel wedge-shaped filter screen makes the spray effect inside the filter screen, and any impurities are removed from the smooth inner wall. flush away. When the pressure difference between the inlet and outlet of the filter returns to normal or the timer set time expires, the electric drain valve is closed and the water flow guide valve is opened. The entire flushing process system works without downtime.

Hot Searches