- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

XPE IXPE Foam

-

Thickness:

-

0.15-15mm, 1-15mm

-

Size:

-

0.5-1.6M wide

-

Product Name:

-

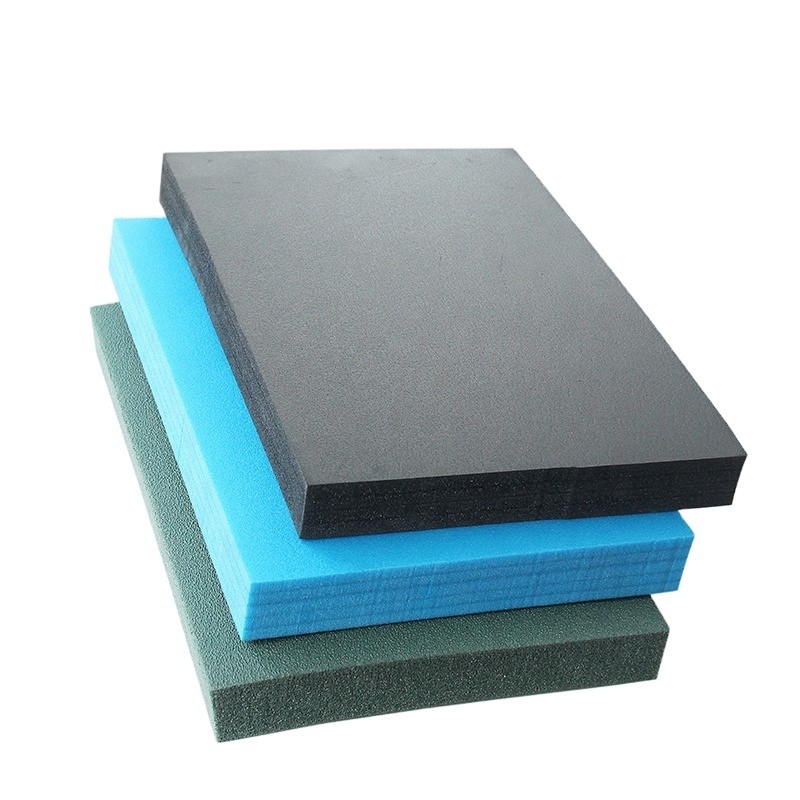

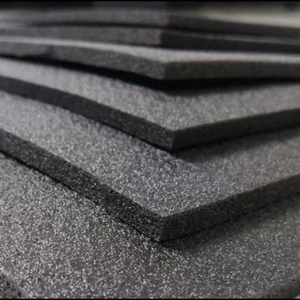

Black Thin Polyethylene Foam Sheets Packing Material

-

density:

-

25-330 Kg/M3

-

Raw material:

-

LDPE

-

size:

-

customized

-

Shape:

-

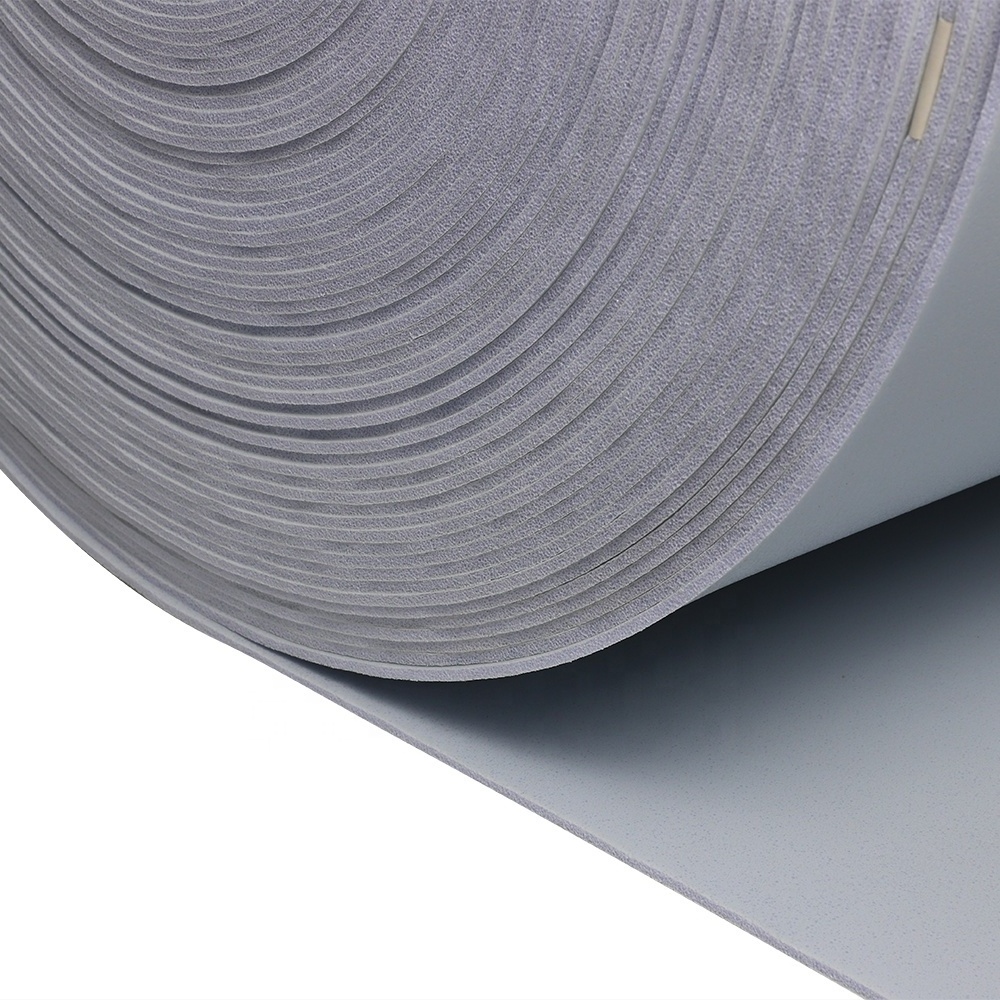

roll or sheet

-

Application:

-

Thermal Insulation

-

Advantage:

-

Delivery Speed

Quick Details

-

Processing Service:

-

Cutting, Moulding

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

CTF

-

Model Number:

-

XPE IXPE Foam

-

Thickness:

-

0.15-15mm, 1-15mm

-

Size:

-

0.5-1.6M wide

-

Product Name:

-

Black Thin Polyethylene Foam Sheets Packing Material

-

density:

-

25-330 Kg/M3

-

Raw material:

-

LDPE

-

size:

-

customized

-

Shape:

-

roll or sheet

-

Application:

-

Thermal Insulation

-

Advantage:

-

Delivery Speed

|

XPE Foam Technical Specification

|

|

|

|

|

|

|

|

|

||||||||

|

Test item

|

Items

|

|

|

|

|

|

|

|

||||||||

|

|

5 Times

|

8 Times

|

10 Times

|

15 Times

|

20 Times

|

25 Times

|

30 Times

|

35 Times

|

||||||||

|

Density kg/m3

|

200±30

|

125±15

|

100±10

|

66.7±8

|

50±6

|

40±4

|

33.3±3

|

28.6±2

|

||||||||

|

Shore Hardness°

|

60~70

|

50~60

|

45~50

|

35~45

|

30~35

|

25~30

|

18~25

|

13~18

|

||||||||

|

Hardness

|

|

|

|

|

|

|

|

|

||||||||

|

Water absorbtion (%)23±2℃,24h

|

≤0.02

|

≤0.02

|

≤0.03

|

≤0.03

|

≤0.04

|

≤0.04

|

≤0.05

|

≤0.05

|

||||||||

|

Heat conductivity (w/m.k)

|

≤0.092

|

≤0.082

|

≤0.072

|

≤0.062

|

≤0.053

|

≤0.047

|

≤0.041

|

≤0.038

|

||||||||

|

K value w/m.k

|

|

|

|

|

|

|

|

|

||||||||

|

IXPE Foam Technical Specification

|

|

|

|

|

|

|

|

|

||||||||

|

Test item

|

Items

|

|

|

|

|

|

|

|

||||||||

|

|

5 Times

|

8 Times

|

10 Times

|

15 Times

|

20 Times

|

25 Times

|

30 Times

|

35 Times

|

||||||||

|

Density kg/m3

|

200±30

|

125±15

|

100±10

|

66.7±8

|

50±6

|

40±4

|

33.3±3

|

28.6±2

|

||||||||

|

Shore Hardness°

|

60~70

|

50~60

|

45~50

|

35~45

|

30~35

|

25~30

|

18~25

|

13~18

|

||||||||

|

|

|

|

|

|

|

|

|

|

||||||||

|

thickness ≤3mm

|

55~65

|

45~55

|

35~45

|

25~35

|

20~25

|

20~25

|

15~20

|

15~20

|

||||||||

|

Water absorbtion (%)23±2℃,24h

|

≤0.02

|

≤0.02

|

≤0.03

|

≤0.03

|

≤0.04

|

≤0.04

|

≤0.05

|

≤0.05

|

||||||||

|

Heat conductivity (w/m.k)

|

≤0.095

|

≤0.084

|

≤0.073

|

≤0.065

|

≤0.055

|

≤0.045

|

≤0.040

|

≤0.040

|

||||||||

|

K value w/m.k

|

|

|

|

|

|

|

|

|

||||||||

Product Paramenters

|

Performance

|

Standard

|

UNITE

|

VALUE

|

|

Flammability

|

FMVSS 302-1998 / UL94 HF-1

|

|

pass

|

|

Heat Conductivity

|

ASTM C518-17

|

W/mk

|

0.032-0.039

|

|

Temperature Resisitance

|

|

℃

|

-40~80

|

|

Water Vapor Transmission Rate

|

GB/T 26253-2010

|

g/m²/day

|

≤1.00

|

|

Reflectivity

|

ASTM C1371-15

|

%

|

95%~97%

|

① XPE foam has a water absorption of 0.01% and a thermal conductivity of 0.037W/mk;

It is lightweight and has a density of 25-333Kg / m3;

② The texture is soft and can be rolled up for easy installation;

③ Good ductility, the theory can be infinitely long;

④ Sound insulation can reach 19dB;

⑤ Flame retardant can achieve B1 level of building fire protection;

Products Description

What is xpe foam?

XPE is a chemical crosslinked polyethylene foam, with low density polyethylene resin and a crosslinking agent and foaming agent through continuous foaming and high temperature, XPE is chemically stable, difficult to decompose, odorless and flexible.

What is ixpe foam?

IXPE (Irradiation cross-linked polyethylene) foam is based on low density polyethylene as raw material, change to independent obturator meshed bubble structure by using electronic irradiation.

It can be compounded with aluminum film, aluminum foil, PE filmor other materials.

Closed Cell Cross-Linked Polyethylene Foam has many good properties

* Acoustic insulation

* Corrosion resistance

* Cushion, buffer

* Lightweight

* Rebound elasticity

* Shock absorption

* Thermal insulation

* Waterproof, moisture-proof

* Weather resistance

* Corrosion resistance

* Cushion, buffer

* Lightweight

* Rebound elasticity

* Shock absorption

* Thermal insulation

* Waterproof, moisture-proof

* Weather resistance

Product Processing

Product Packaging and Shipping

Application

PE Foam For tape

Both cross-linked Polyethylene foam packaging and irradiation polyethylene foam insert can offer excellent vibration dampening for your products.

XLPE foam has a smoother surface and better technical properties compared with XPE foam. Both of them have excellent properties on moisture resistance, durability, resilience and heat insulation. They are excellent to be as foam packaging insert for industrial,instruments and electronics.

Custom polyethylene foam insert can protect your products with long term cushioning.

Long-term Durability and Cushioning

Ideal Shock Absorption

Available in various colors, densities and easy to be custom fabricated

Packing insert

Cap gasket

Application

Polyolefin Foam In Automotive

1.Product solutions in instrument panels, door panels, door armrests.

2.Lightweight product solutions for automotive vent pipes.

3.Headrest cover for PIP infusion foam technology.

3.Headrest cover for PIP infusion foam technology.

4.Waterproof and soundproof car door membrane.

5.Foam products for vibration damping and sound insulation of cockpit front wall.

6.Solutions for ceiling products with excellent thermal insulation.

7.Automotive NVH product solutions.

7.Automotive NVH product solutions.

Automotive NVH solution

XPE / IXPE in the car's front wall, floor,fenders, engine insulationpads, pad,.more than 30 parts to be applied, it can be solve the NVH problem well.

Hot Searches