- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V/380V

-

Power:

-

(55-110)*2kw

-

Dimension(L*W*H):

-

1470 * 1550 * 970

-

Weight (KG):

-

2990

-

Name:

-

Wood Crusher Machine

-

Application:

-

Crush Wood Logs Making Sawdust

-

Keywords:

-

High Output Mobile Wood Crusher

-

COLOR:

-

Customers' Requirement

-

Advantage:

-

High Efficiency Low Energy

-

After-sale Service:

-

24 Hours Online

-

Capacity:

-

1-3t/h

-

Package:

-

Standard Wooden Crate

-

Certification:

-

CE ISO

-

Function:

-

Crushine Wood

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Xrido

-

Marketing Type:

-

New Product 2022

-

Voltage:

-

220V/380V

-

Power:

-

(55-110)*2kw

-

Dimension(L*W*H):

-

1470 * 1550 * 970

-

Weight (KG):

-

2990

-

Name:

-

Wood Crusher Machine

-

Application:

-

Crush Wood Logs Making Sawdust

-

Keywords:

-

High Output Mobile Wood Crusher

-

COLOR:

-

Customers' Requirement

-

Advantage:

-

High Efficiency Low Energy

-

After-sale Service:

-

24 Hours Online

-

Capacity:

-

1-3t/h

-

Package:

-

Standard Wooden Crate

-

Certification:

-

CE ISO

-

Function:

-

Crushine Wood

Products Description

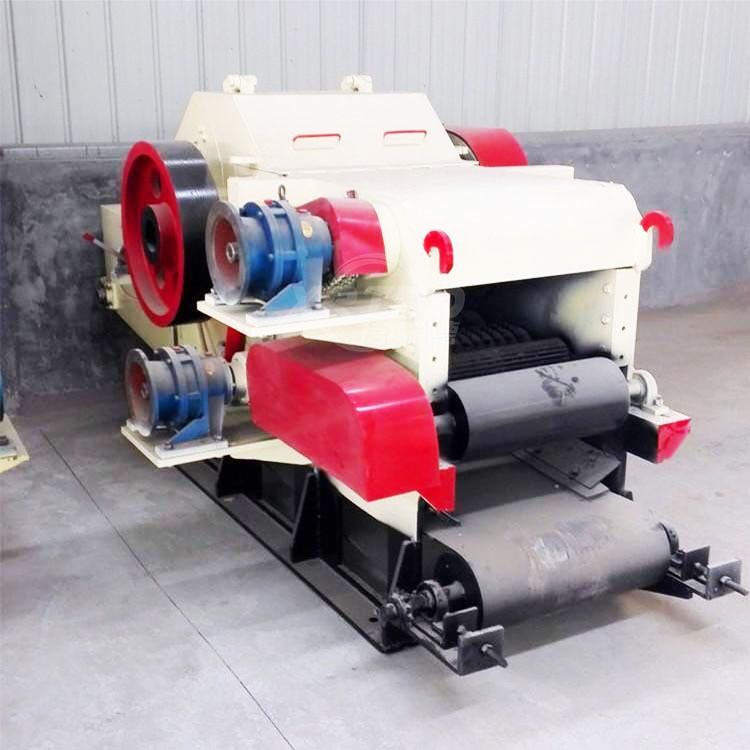

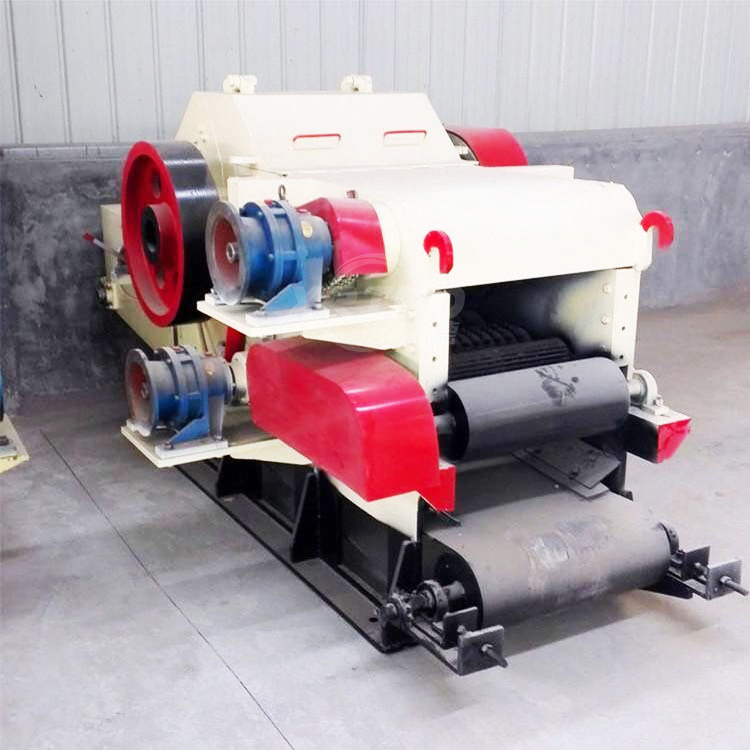

Log Sawmill Waste Drum Wood Shredder Cutter Machine Wood Chipper Price

Wood crusher is mainly used for processing pine, weed tree, cedar wood,bamboo,etc. It's more suitable for processing mushroom substrate.It's convenient to cutting bamboo, thatch, maize straw,sorghum stalk and such fiber stem materials. This wood crusher can also be used for production of chipboard, fiberboard, and wood plate.

Wood crusher advantage: Wood material can be effectively crushed in the chamber,when crusher is working.This wood crusher has advantage of high capacity,low energy cost, high efficiency, average output size, low noise, no pollution to environment,easy handling,and easy maintenance.

1、This crusher’s capacity is influenced by material physical properties,way of material input,input material size and working condition.

2、Xrido Machinery aims to providing the best products and most ideal economic solution.

3、Our technical experts will provide help at any time,and we hope to build a long term partership with you.

Main Application

This serial drum chipper is made up of seat, knife rotor, upper and down feeding roller, hydraulic pressure system, and electric control system. The seat adopts high strength steel plate welded and overall elimination stress treatment which proves strength and service life. The in-feed rollers adopt the dismantle structure for easy to replace. The bottom cutter seat uses hydraulic pressure oil cylinder to change bed knife conveniently and fast, meanwhile the cutting roller adopts protective plates structure to extend service life.

Customer Site

Product Paramenters

|

Specifications

|

BX215

|

|

|

|

|||

|

160 * 400 mmImport material size (mm)

|

800mm

|

|

|

|

|||

|

Number of flying knives (pc)

|

2

|

|

|

|

|||

|

revolving speed of knife roll (rpm)

|

592rpm

|

|

|

|

|||

|

Maximum diameter of raw material (mm)

|

160 mm

|

|

|

|

|||

|

Feed speed

|

38 m/min

|

|

|

|

|||

|

Processing raw material max diameter

|

160mm

|

|

|

|

|||

|

Wood Chips length

|

30mm

|

|

|

|

|||

|

Main motor power

|

132 kw

|

|

|

|

|||

|

Shape size (mm)

|

1470 * 1550 * 970

|

|

|

|

|||

|

Weight (kg)

|

2990

|

|

|

|

|||

Customer Photos

Hot Searches