- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

1600*200*50mm

-

Weight (T):

-

18 T

-

Power (kW):

-

21

-

Product Name:

-

Annealing furnace

-

Rated Voltage:

-

380V/50HZ/3P

-

Max temperature:

-

1150℃

-

Output:

-

28kg/h

-

Application:

-

Annealing

-

After-sales Service Provided:

-

Online support

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Huichengsheng

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

1600*200*50mm

-

Weight (T):

-

18 T

-

Power (kW):

-

21

-

Product Name:

-

Annealing furnace

-

Rated Voltage:

-

380V/50HZ/3P

-

Max temperature:

-

1150℃

-

Output:

-

28kg/h

-

Application:

-

Annealing

-

After-sales Service Provided:

-

Online support

Product Description

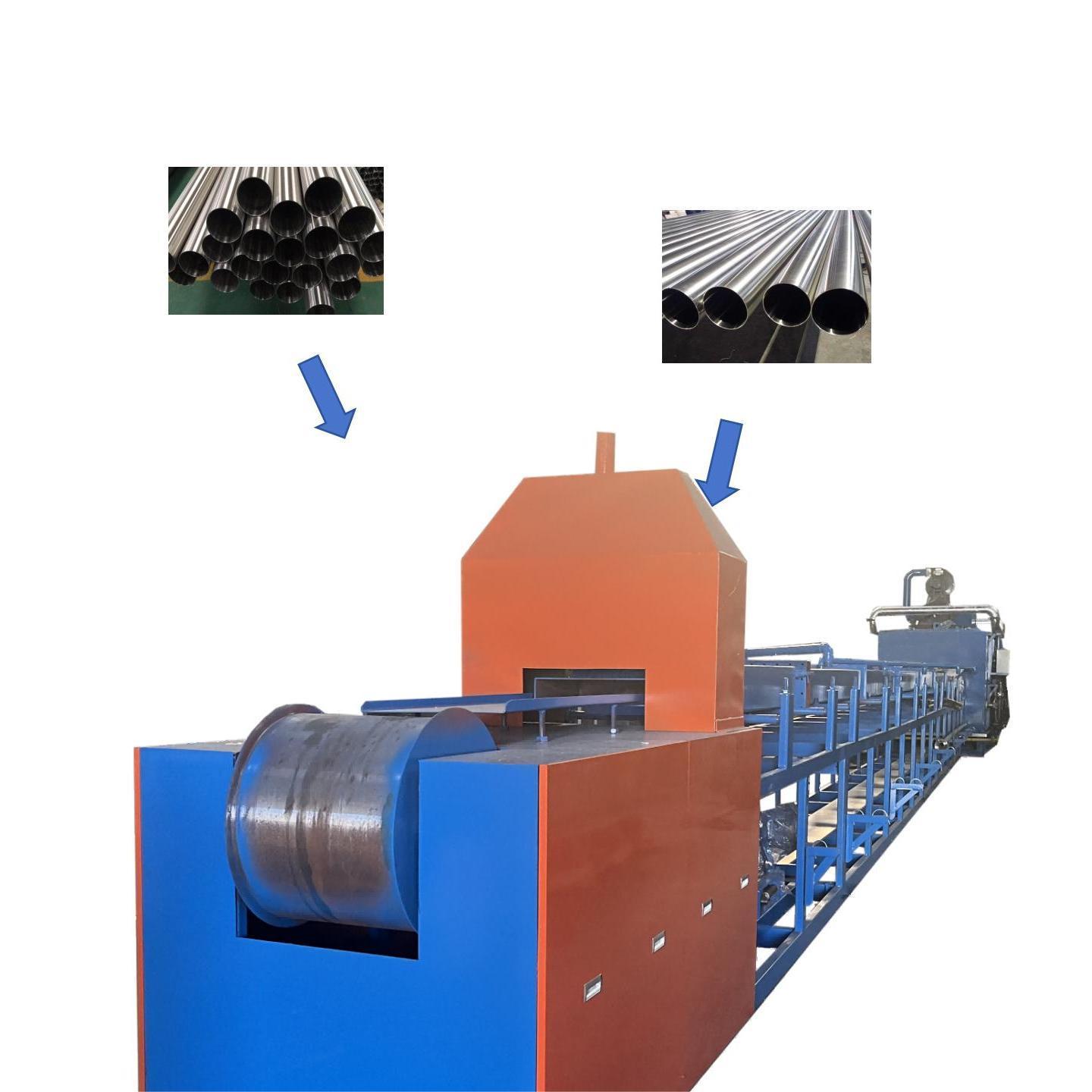

The continuous gas shielded bright heat treatment furnace is mainly used for the continuous bright quenching of Martensitic stainless steel, bright annealing of austenitic stainless steel ,various copper materials and copper alloy intermediate recrystallization annealing ,final annealing and stress relief treatment, and so on.

After the product is treated by the equipment, the surface is bright without oxidation. The furnace boasts stylish design, rational structure, energy saving, high heat efficiency, stable production quality, safe and easy use, not generating industrial pollution.

|

Main Model And Technical Parameters

|

|

|

|

|

|

|

Main Model And Technical Parameters

|

|||||||

|

Model

|

Rated power

(kw)

|

Heating Zone

Number

|

Rated

Temperature (℃)

|

Hearth Size

L*W*H(MM) |

|

|

Output

(KG)

|

|||||||

|

HCS6-15

|

20

|

3

|

1150

|

1600

|

155

|

40

|

22

|

|||||||

|

HCS6-20

|

21

|

3

|

1150

|

1600

|

200

|

50

|

28

|

|||||||

|

HCS8-20

|

30

|

3

|

1150

|

2000

|

200

|

60

|

40

|

|||||||

|

HCS12-15

|

45

|

3

|

1150

|

2600

|

155

|

50

|

50

|

|||||||

|

HCS16-20

|

60

|

4

|

1150

|

3500

|

200

|

60

|

80

|

|||||||

|

HCS16-25

|

70

|

4

|

1150

|

3500

|

250

|

80

|

100

|

|||||||

|

HCS16-30

|

85

|

4

|

1150

|

3500

|

300

|

80

|

120

|

|||||||

|

HCS20-35

|

120

|

5

|

1150

|

4500

|

350

|

120

|

200

|

|||||||

|

HCS20-50

|

150

|

5

|

1150

|

4500

|

500

|

200

|

280

|

|||||||

|

HCS29-72

|

210

|

8

|

1150

|

5000

|

720

|

300

|

400

|

|||||||

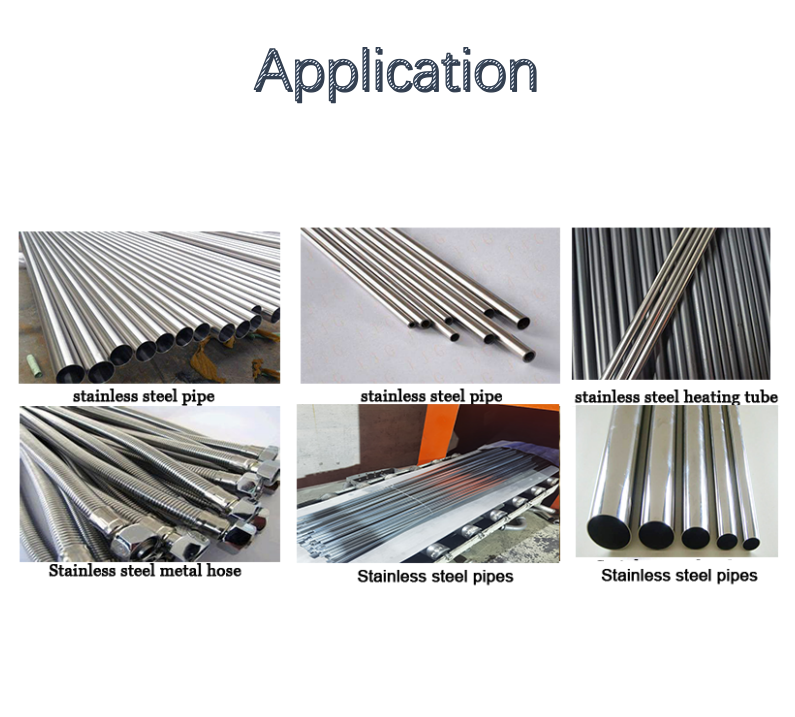

Application

Support

free sample testing

, combined with our heat treatment experience, allows you to get the heat treatment profile quickly and

reduce your exploration time!

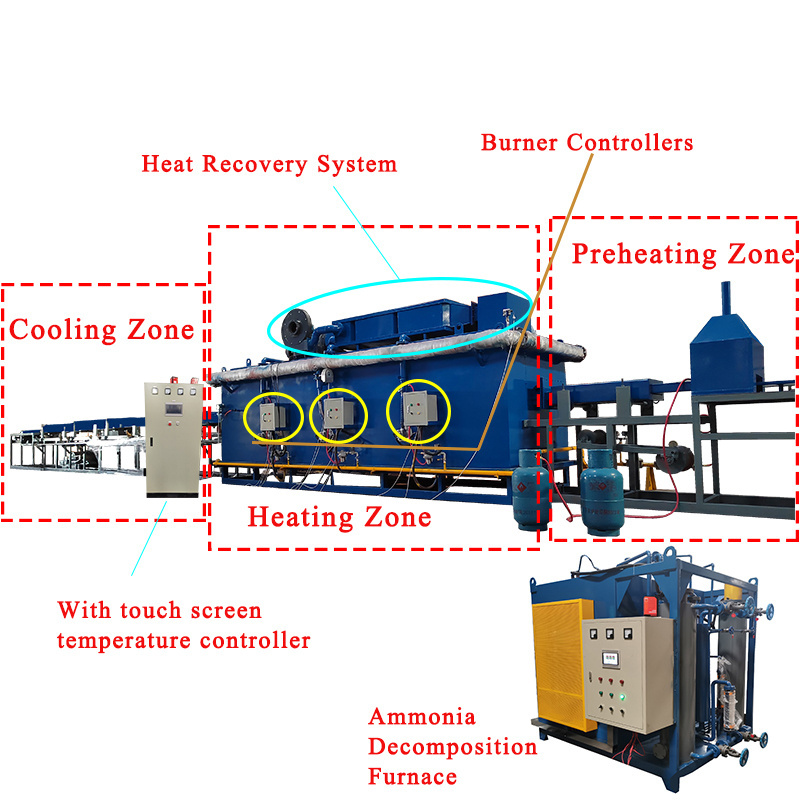

Product features and advantages

Muffle

310S high temperature stainless steel,8mm thickness. Arc type, this design will help the workpiece can pass furnace after using of a period of time, even if the deformation.There are number of ribs above the muffle which is not easy to deformation with long service life.

Heating Wire

High-temp.resistance wire(OCr27A17MO2)is used.The melting point is1450℃,the working temperature can reach 1200 ℃. Heating elements are arranged in an upper-lower removable manner to ease repair or replacing; replacing resistance wire has no impact on production.

Ammiona Cracker

Using ammonia decomposition atmosphere as high reducibility protective atmosphere,without oxidation heating workpiece at high temperature, no oxidation and in the subsequent cooling, to achieve the effect of light treatment.

Electric Control System

Color touch screen, electronic control button,visualization,easy to operate.Temperature control precision of±1°c.

All important components are use international famous brand, such as: Schneider Siemens,Omron,Mitsubishi and so on.

P

LC HMI System

1.View the temperature curve.

2.Allowing user record, export and save temperature data on PC via USB stick.

3.Setting and adjust the parameter by touch screen.

4.Simultaneous LCD display of actual temperature VS set point.

5.It is easy to edit in the touch screen and a new operator can learn quickly and easy to get started.

After sales service

About us

We are not only a manufacturer of continuous atmosphere controlled furnaces, but also provide annealing heat treatment services for local company using our own furnaces.

In this way, we can learn more about how our furnace are being used and get innovate. We also provide sample test service!

Our customer

FAQ

01

Q: Are you trade company or manufacturer?

A: We are an enterprise with sales, R&D, manufacturing and with CE certificate.

02 Q: Whether to provide quality assurance and complete after-sales support? Or say, does engineers available to service overseas?

A: Yes! Warranty period of our heat treatment furnace machine mechanical part is 12 months, if necessary,we support the site installation, commissioning, technical guidance,and after-sales maintenance support.

03 Q: How can I know what kinds of the furnace and which size suits my needs best?

A: Before quoting,please kindly tell me what's your product and what's your requrie capacity for per day? It will be more easier for us to advise you the most suitable furnace for you to make you cost to the minimum!

04 Q: Does customized is acceptable?

A: Yes, we accept customized. Customized service is one art of Huichengsheng core advantage.

Hot Searches