- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

3500*3200*2800mm

-

Year:

-

new

-

Power (kW):

-

300 kW

-

Weight (KG):

-

40000 KG

-

Applicable Industries:

-

Rubber powder production line

-

Name:

-

Rubber powder production line

-

Material:

-

waste tires and waste rubber

-

Service life:

-

≥15 Years

-

Usage:

-

Used Tire Recyling

-

Advantage:

-

Energy Saving 1/3 Energy

-

End product:

-

Rubber Power

-

Color:

-

Customers' Demand

-

Raw material:

-

Waste Tyre

-

Application:

-

Rubbers Recycling Industry

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Yisonhonda

-

Voltage:

-

220V to 510V

-

Dimension(L*W*H):

-

3500*3200*2800mm

-

Year:

-

new

-

Power (kW):

-

300 kW

-

Weight (KG):

-

40000 KG

-

Applicable Industries:

-

Rubber powder production line

-

Name:

-

Rubber powder production line

-

Material:

-

waste tires and waste rubber

-

Service life:

-

≥15 Years

-

Usage:

-

Used Tire Recyling

-

Advantage:

-

Energy Saving 1/3 Energy

-

End product:

-

Rubber Power

-

Color:

-

Customers' Demand

-

Raw material:

-

Waste Tyre

-

Application:

-

Rubbers Recycling Industry

scrap tire recycling machine to make rubber powder price

Product Description

high output automatic tyre recycling machine to make rubber powder/ waste tyre recycling machine is suitable for different kinds of scrap tires, and we can provide you the best solution based on your different tires.

|

Capacity

|

500-10000kg/h

|

|

Scope of application

|

The diameter of the tire:400-3000mm

|

|

Output size

|

5-100 mesh, can be Customized

|

|

Complete separation

|

The rubber Crumbs, Steel and Fiber can be separated automatically. Adopt PLC control system, it is only needs 4-6 persons to operate a Tire recycling(granule)production line with 3000 kg/h capacity. Low energy consumption. The installed powder of Tire recycling production(granule)line with capacity 3000 kg/h is about 800 kw.

|

|

Equipment required area

|

About 680 square meter, 7m height

|

|

Characteristic of blade

|

Long service life.High utilization, Multiple maintenances.

|

Details Images

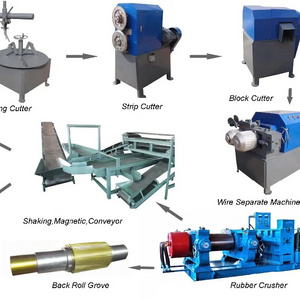

Working flow:

Waste tire---Wire drawing machine---Rubber shredder--- Steel wire separating machine---magnetic separating ---Rubber powder.

1. Steel wire drawing machine--extract the thick steel wire.

2. Conveyor-Transport the tire to the shredder.

3. Twin-shaft shredder--Shears the tire into 5- 10cm blocks;

4. Recirculation system--To control the size of shreds going to the rapers;

5. Raspers-Reduce the shreds into 15. 20mm chips and liberates steel from the rubber;

6. Over belt magnet--Separation of liberated steel from the rubber chips;

7. Vibratory feeder--Transports the rubber chips;

8. Rubber granulator machine--Size reduction of the chips to 1-4mm granules and liberates the textile fraction to air flow separation.

9. Grinder machine --Grinder rubber powder.

10.Central de-dusting unit--Remove dust and fines from the system and filter the air before returning it to the atmosphere.

Packing&Shipping

Hot Searches