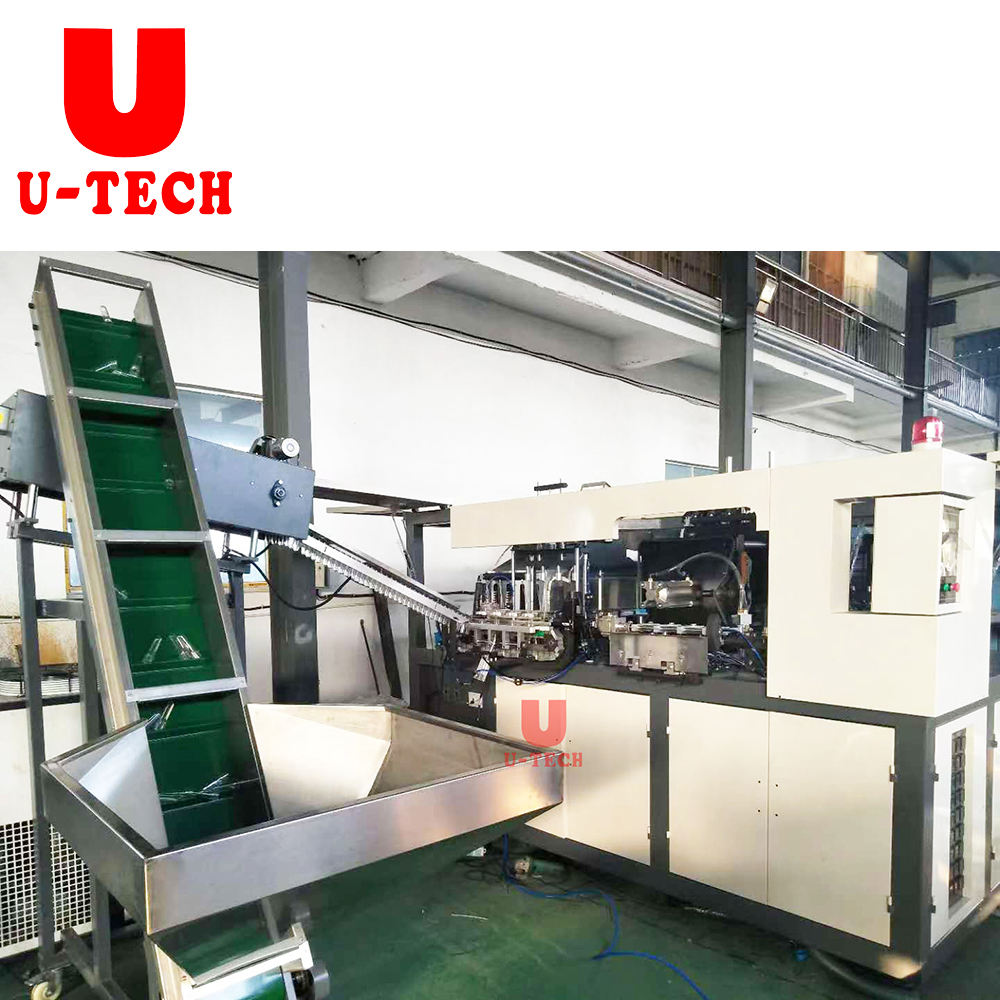

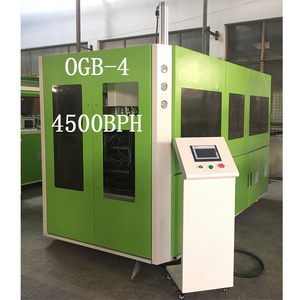

BST-4000 automatic PET Can Bottle stretch blow molding machine is one of the newest products for our customer. Its strongest point is energy savings. Adopting high pressure clamping, automatic stretch blow molding machine makes self-adjustment in accordance with the different pressure needed during production, thus ensures the super clamping force. While the high pressure sealing system with automatic adjustment permits that mold sealing is under condition of 100% air tightness before blowing and avoid air energy loss owing to incomplete air tightness. With such effective control over air energy and power, it takes a big part to lower costs and improve efficiency.

- Product Details

- {{item.text}}

Quick Details

-

Bottle Volume(ml):

-

1500 ml

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

U TECH

-

Year:

-

2022

-

Voltage:

-

380V/220V

-

Dimension(L*W*H):

-

4.5*1.5*1.9M

-

Hollow part volume:

-

380*460mm

-

Clamping Force (kN):

-

170

-

Power (kW):

-

30

-

Weight (KG):

-

4500 KG

-

Model Number:

-

UT-4000

-

Product name:

-

Automatic stretch PET Blowing Molding Machine

-

Capacity:

-

3500-4000pcs/h

-

Cavity:

-

4-cavity

-

Suitable bottle:

-

Drink PET Can Bottle

-

Type:

-

Stretch Pet Blow Moulding

-

Material:

-

Stainless Steel

-

Key words:

-

Pet Blowing Machine Automatic

-

After-sales Service Provided:

-

Field maintenance and repair service

Quick Details

-

Neck Diameter(mm):

-

160 mm

-

Max.Bottle Diameter(mm):

-

500 mm

-

Max.Bottle Height(mm):

-

800 mm

-

Bottle Volume(ml):

-

1500 ml

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

U TECH

-

Year:

-

2022

-

Voltage:

-

380V/220V

-

Dimension(L*W*H):

-

4.5*1.5*1.9M

-

Hollow part volume:

-

380*460mm

-

Clamping Force (kN):

-

170

-

Power (kW):

-

30

-

Weight (KG):

-

4500 KG

-

Model Number:

-

UT-4000

-

Product name:

-

Automatic stretch PET Blowing Molding Machine

-

Capacity:

-

3500-4000pcs/h

-

Cavity:

-

4-cavity

-

Suitable bottle:

-

Drink PET Can Bottle

-

Type:

-

Stretch Pet Blow Moulding

-

Material:

-

Stainless Steel

-

Key words:

-

Pet Blowing Machine Automatic

-

After-sales Service Provided:

-

Field maintenance and repair service

Product Intruduction

U TECH Machine Full Automatic PET Can Bottle Blow Molding Machine.

Machine details

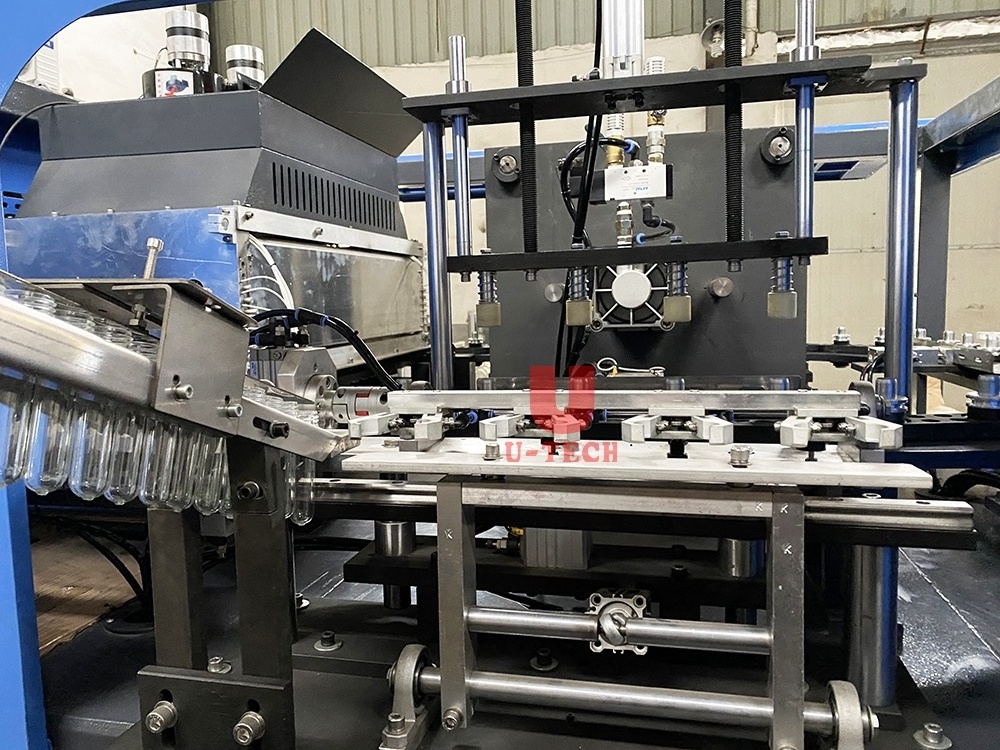

Servo System On Main Transmission.

The transmission adopts servomotor for positioning that can orientate the preform-heating base quickly, accurately and steadily when the machine starts and running.

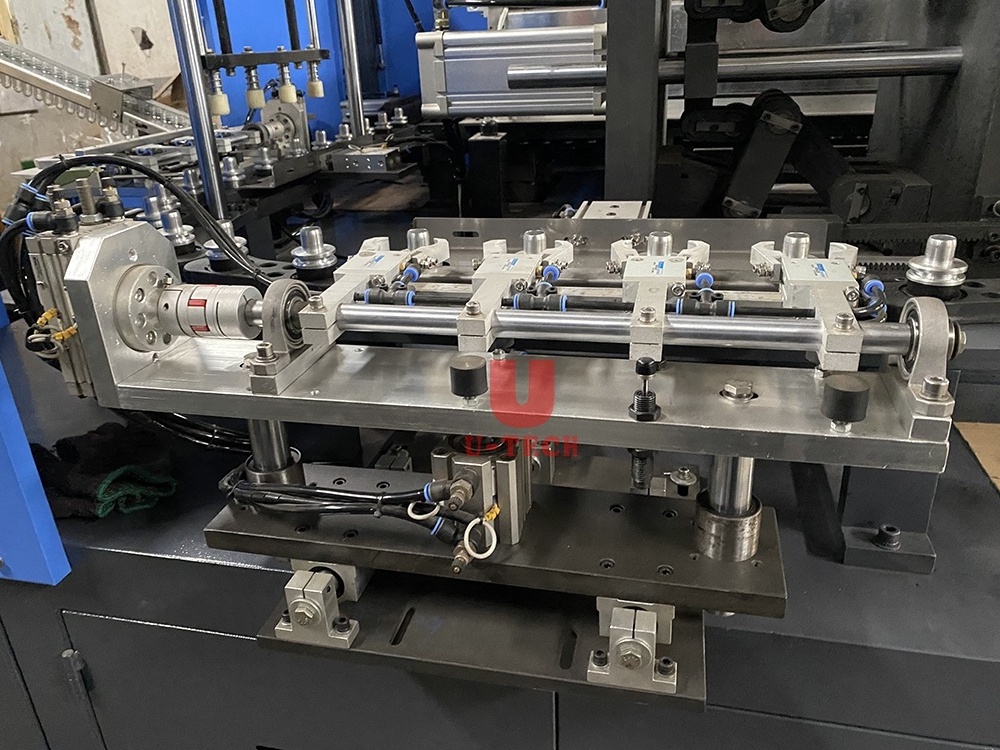

Clamping System & Stretching.

*Adopts servo motor to drive the two cranks to control the clamping system which can shorten the mold-clamping time and improve productivity, and also solve the swelling mold and big joint line problem with the effect of pressurize plate.

* Servo motor using for stretching to ensure the bottle blowing speed faster and more stable bottle quality.

* Servo motor using for stretching to ensure the bottle blowing speed faster and more stable bottle quality.

Easy To Change Bottle Shape.

*Drawer type mold structure design is easy for mold changing. Within one hour can change a mold on the condition of same bottle neck diameter.

U TECH Service

What U TECH Machine can do for you ?

Bottle Design

Our designers can design bottle styles according to your requirements.

Machine Layout.

We will confirm the machine layout according to your factory.

Sample Project.

We can provide a sample project for you to visit.

Working Process

Auto Preform Unscrambler System.

*Adopts one-way preform-feeding structure and preform-separating by servo motor structure which solve the preform block and abrasion problem.

*There are two photoelectric sensors to control preform-loading motor and preform-separating cylinder that will warn the operator to add the preforms into the hopper when lacks preform instead of stopping the machine.

*Adopts one-way preform-feeding structure and preform-separating by servo motor structure which solve the preform block and abrasion problem.

*There are two photoelectric sensors to control preform-loading motor and preform-separating cylinder that will warn the operator to add the preforms into the hopper when lacks preform instead of stopping the machine.

New Heating System.

*Perfect heating system design decrease power consumption.

*Special oven design helps power saving and easy maintain.

*Each lamp position and temperature can be adjusted.

*Cycle air-cooling system keeps the oven temperature constantly.

*Special oven design helps power saving and easy maintain.

*Each lamp position and temperature can be adjusted.

*Cycle air-cooling system keeps the oven temperature constantly.

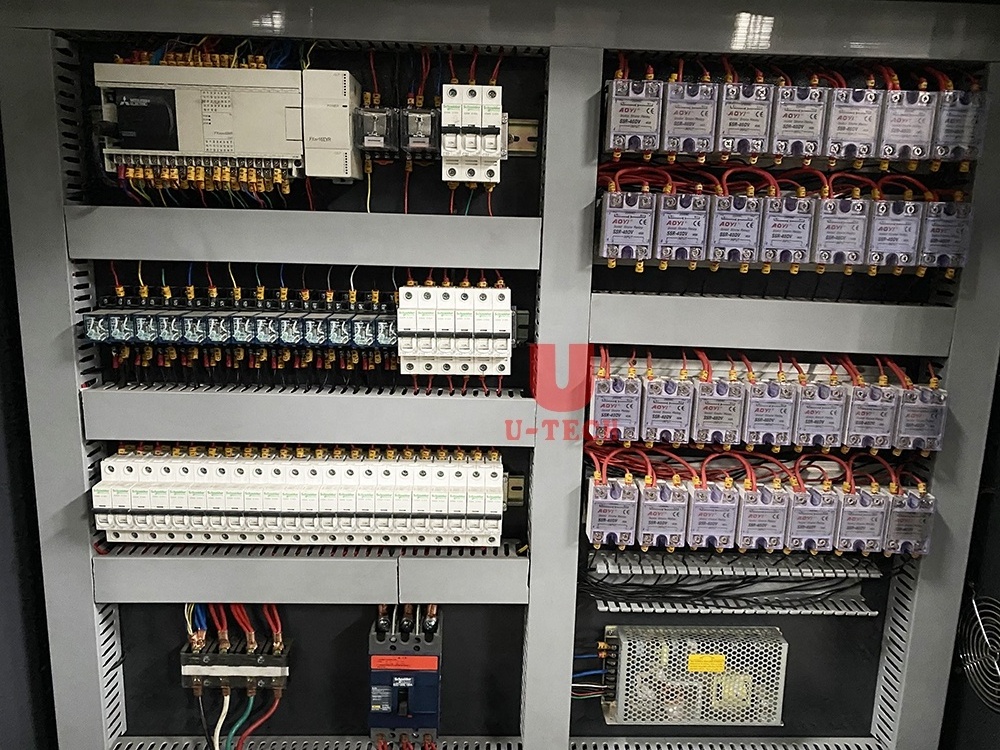

Intelligent Human-Machine Interface.

*Human-machine interface control, easy operate and monitor.

*Live production information supervise, auto record production data everyday

*Failure warning and troubleshooting.

*Live production information supervise, auto record production data everyday

*Failure warning and troubleshooting.

Technical Parameters

|

TYPE

|

ITEM

|

UNIT

|

Technical data

|

|

Container |

Product material

|

/

|

PET

|

|

|

Container volume

|

L

|

0.05-2.0

|

|

|

Theoretic output

|

Psc/hr

|

5500

|

|

|

Preform length

|

MM

|

50-200

|

|

|

Max height of bottle

|

MM

|

320

|

|

Molding |

Preform inner diameter

|

mm

|

15-60

|

|

|

Bottle diameter

|

mm

|

35-110

|

|

|

Max mold plate dimension (L × W)

|

mm

|

380 × 460

|

|

|

Max mold thickness

|

mm

|

200

|

|

Air compressor |

High pressure compressor

|

M3/Mpa

|

1.2/30 × 3set

|

|

|

Locking force

|

KN

|

170

|

|

|

Mold opening stroke (adjustable)

|

mm

|

200

|

|

|

Low pressure compressor

|

M3/Mpa

|

2.0/10 × 1sets

|

|

|

Air dryer

|

M3/Mpa

|

2.0/30 × 1sets

|

|

Main machine electricity

|

Power

|

KW

|

30

|

|

|

Voltage / frequency

|

V/Hz

|

380/50hz

|

Application

|

U TECH Machine

|

|

|

|

Packing.

|

Conventional packaging:

inside is wrapped with PE film outside is wooden box |

|

|

Delivery.

|

The normal delivery period is 45 days, depending on the equipment, the specific time is about 30 to 45 days.

|

|

About U TECH

Zhangjiagang U TECH Machine Co.,Ltd

1 / Standardized workshop of total 20,000 square meters.

2 / The equipment will be tested and run for 48 hours before leaving the factory, to ensure the smooth working of water pipeline,and pneumatic, electrical and mechnical stability.

3 / Sufficient stock of spare parts ensures the timely delivery and supply of spare parts.

2 / The equipment will be tested and run for 48 hours before leaving the factory, to ensure the smooth working of water pipeline,and pneumatic, electrical and mechnical stability.

3 / Sufficient stock of spare parts ensures the timely delivery and supply of spare parts.

U TECH Machine Sales Manager Team and Engineer Team.

1 / Professional installation team who can speak fluent English can help customers make benefits in a shortest time.

2 / The engineers are experienced. We can produce different products with different capacity and work out reasonable flow chart as per customers' requirements to save space.

2 / The engineers are experienced. We can produce different products with different capacity and work out reasonable flow chart as per customers' requirements to save space.

Certifications

FAQ

YOU ARE WELCOME TO OUR FACTORY AT ANY TIME.

● If we can fullfill your request and you interested in our products, you may pay a visit to U TECH Machine site

● The meaning of visiting supplier, because seeing is believing, U TECH Machine with own manufacture and developed& research team,we can send you engineers and make sure your after sales service.

HOW TO GUARANTEE YOUR FUNDS TO BE SAFE AND DELIVERY TO BE ON TIME?

● Through Alibaba letter guarantee service, it will ensure the on time delivery and the quality of the equipment you want to buy.

● By letter of credit, you can lock the delivery time easily.

● After the factory visit, You can ensure the facticity of our bank account.

SEE U TECH MACHINE HOW TO ENSURE THE QUALITY!

● In order to ensure the accuracy of each part, we are equipped with a variety of professional processing equipment and we have accumulated professional processing methods over the past years.

● Each component before assembly needs strictly control by inspecting personnel.

● Each assembly is in charged by a master who has working experience for more than 5 years

●After all the equipment are completed, we will connect all the machines and run the full production line for at least 48 hours to ensure the stable running in customers' factory

THE AFTER-SALE SERVICE OF U TECH MACHINE!

● After finish the production, we will debug the production line, take photos, videos and send them to customers via mail or instant tools

● After the commissioning, we will package the equipment by standard export package for shipment.

● According to the customer's request, we can arrange our engineers to customers' factory to do the installation and training.

● Engineers, sales managers and after-sales service manager will form a after-sales team, online and off line, to follow the customers' project.

● If we can fullfill your request and you interested in our products, you may pay a visit to U TECH Machine site

● The meaning of visiting supplier, because seeing is believing, U TECH Machine with own manufacture and developed& research team,we can send you engineers and make sure your after sales service.

HOW TO GUARANTEE YOUR FUNDS TO BE SAFE AND DELIVERY TO BE ON TIME?

● Through Alibaba letter guarantee service, it will ensure the on time delivery and the quality of the equipment you want to buy.

● By letter of credit, you can lock the delivery time easily.

● After the factory visit, You can ensure the facticity of our bank account.

SEE U TECH MACHINE HOW TO ENSURE THE QUALITY!

● In order to ensure the accuracy of each part, we are equipped with a variety of professional processing equipment and we have accumulated professional processing methods over the past years.

● Each component before assembly needs strictly control by inspecting personnel.

● Each assembly is in charged by a master who has working experience for more than 5 years

●After all the equipment are completed, we will connect all the machines and run the full production line for at least 48 hours to ensure the stable running in customers' factory

THE AFTER-SALE SERVICE OF U TECH MACHINE!

● After finish the production, we will debug the production line, take photos, videos and send them to customers via mail or instant tools

● After the commissioning, we will package the equipment by standard export package for shipment.

● According to the customer's request, we can arrange our engineers to customers' factory to do the installation and training.

● Engineers, sales managers and after-sales service manager will form a after-sales team, online and off line, to follow the customers' project.

If you are interested in our machine please contact with me anytime

Hot Searches