- Product Details

- {{item.text}}

Quick Details

-

Screw Speed (rpm):

-

1480 rpm

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Sumino

-

Voltage:

-

380V 3P 50Hz or customer's requirement

-

Dimension(L*W*H):

-

According to the actual condition

-

Power (kW):

-

450

-

Weight:

-

160000 KG

-

Name:

-

PE Air Bubble Film machine

-

Raw material:

-

PE + CaCo3

-

Product Width:

-

1400(costomized)

-

Motor:

-

ABB

-

PLC:

-

SIEMENS

-

Control:

-

PLC+Touch Screen

-

Product Thickness:

-

0.15-0.4mm

-

Linear Speed of Machine (m/min):

-

150

-

Color:

-

Customer Choice

-

Keywords:

-

pe breathable film machine

Quick Details

-

Screw Design:

-

Single-screw

-

Screw L/D Ratio:

-

30:1

-

Screw diameter (mm):

-

135 mm

-

Screw Speed (rpm):

-

1480 rpm

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Sumino

-

Voltage:

-

380V 3P 50Hz or customer's requirement

-

Dimension(L*W*H):

-

According to the actual condition

-

Power (kW):

-

450

-

Weight:

-

160000 KG

-

Name:

-

PE Air Bubble Film machine

-

Raw material:

-

PE + CaCo3

-

Product Width:

-

1400(costomized)

-

Motor:

-

ABB

-

PLC:

-

SIEMENS

-

Control:

-

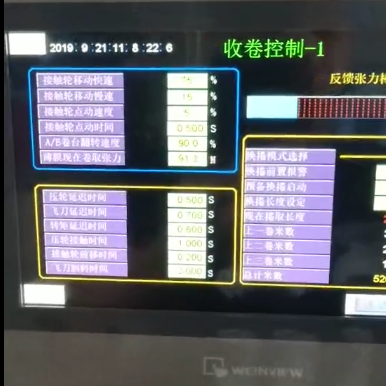

PLC+Touch Screen

-

Product Thickness:

-

0.15-0.4mm

-

Linear Speed of Machine (m/min):

-

150

-

Color:

-

Customer Choice

-

Keywords:

-

pe breathable film machine

Products Description

Multi-function Coating Machine Drying Styling Breathable Nylon Fabric Coating Machine

The PE breathable film extrusion line produces the PE breathable film by mainly using the PE breathable colloidal particles. It adopts the most advanced technologies in the world, among which the extrusion, cast uni-axial stretching technologies play important parts in the whole production.

Features of

PE Breathable Film

1. It is equipped with the on-line extrusion and recycling system for recycling the edge trim.

2. The vertical or horizontal stretching unit sophisticatedly designed enables convenient and safe film hauling-off. The stretch ratio is adjustable according to actual needs.

3. The complete PE breathable film extrusion line is equipped with the touch screen, PLC control system and various

specially-designed protection switches. Hence, the operation is more simple, safe and convenient.

4. The up-to-date winding tension control unit provides precise, stable and reliable tension measurement.

5. The on-line slitting unit or the on-line printing unit is optional to achieve automated flow production. By this way, the

labor cost will be also saved.

Characteristics of PE Breathable Film

1. It is equipped with the on-line extrusion and recycling system for recycling the edge trim.

2. The vertical or horizontal stretching unit sophisticatedly designed enables convenient and safe film hauling-off. The stretch ratio is adjustable according to actual needs.

3. The complete PE breathable film extrusion line is equipped with the touch screen, PLC control system and various

specially-designed protection switches. Hence, the operation is more simple, safe and convenient.

4. The up-to-date winding tension control unit provides precise, stable and reliable tension measurement.

5. The on-line slitting unit or the on-line printing unit is optional to achieve automated flow production. By this way, the

labor cost will be also saved.

Characteristics of PE Breathable Film

1. Produced by our PE breathable film extrusion line, it is a new generation of breathable film with unique cellular structure.

These high-density micropores distributed on the surface of film have breathable and waterproof functions for they can prevent liquid leakage but let the vapor or other gas molecules pass through. For this reason, this film is applicable to the sanitary napkin and the baby diaper to make the water vapor in the water absorption layer exhaust and make people feel comfortable.

2. It also features softness, non-toxicity, pure whiteness, high purity, etc.

These high-density micropores distributed on the surface of film have breathable and waterproof functions for they can prevent liquid leakage but let the vapor or other gas molecules pass through. For this reason, this film is applicable to the sanitary napkin and the baby diaper to make the water vapor in the water absorption layer exhaust and make people feel comfortable.

2. It also features softness, non-toxicity, pure whiteness, high purity, etc.

Parameters of Our Production Line

|

|

|

|

|

|

||||

|

Model (mm) SM-TQ-Z

|

1700

|

2000

|

2200

|

|

Screw Diameter (mm)

|

135

|

135

|

150

|

|

Length-diameter Ratio of Screw (L/D)

|

35:1

|

35:1

|

35:1

|

|

Width of Die (mm)

|

2150

|

2500

|

2800

|

|

Width of Finished Film (mm)

|

1700

|

2000

|

2200

|

|

Gram Weight of Finished Film (g/m2)

|

20-40

|

20-40

|

20-40

|

|

Maximum Extrusion Capacity (kg/h)

|

380

|

450

|

550

|

|

Linear Speed of Machine (m/min)

|

150

|

150

|

150

|

|

Total Installed Power (KW)

|

450

|

550

|

580

|

|

Overall Dimensions (L×W×H)(m)

|

23×11×4.5

|

24×12×4.5

|

25×12×4.5

|

|

Weight (T)

|

50

|

60

|

65

|

Details Images

Product Application

1. Hygienic products: This film produced by

the PE breathable film extrusion line can be used in the sanitary napkin, sanitary pad, baby diaper, etc.

2. Medical supplies: It can be applied in the

medical surgical isolation gown and the disposable bedspread.

3. Commodities: It is usable for the raincoat,

glove, raglan sleeve, waterproof cloth and so on.

4. Building materials: It also can be used as

the breathable and waterproof material, anti-dew film, etc.

the PE breathable film extrusion line can be used in the sanitary napkin, sanitary pad, baby diaper, etc.

2. Medical supplies: It can be applied in the

medical surgical isolation gown and the disposable bedspread.

3. Commodities: It is usable for the raincoat,

glove, raglan sleeve, waterproof cloth and so on.

4. Building materials: It also can be used as

the breathable and waterproof material, anti-dew film, etc.

BOPP bidirectional stretch film

Non Woven Fabric Machine

PP Melt Blown Fabric Machine

Hot Searches