- Product Details

- {{item.text}}

Quick Details

-

Warranty:

-

1 year

-

Brand Name:

-

SUNCENTER

-

Model Number:

-

DGG800

-

Place of Origin:

-

Guangdong, China

-

Usage:

-

Water

-

Power:

-

Pneumatic

-

Standard or Nonstandard:

-

Standard

-

Theory:

-

Reciprocating Pump

-

Max pressure:

-

10bar-6400 bar

-

Applicable test product:

-

pipes/hose/tube/guage/sensor/valves/cylinders

-

Power Supply:

-

Pneumatic(Air driven)

-

Certificate:

-

ISO9001:2008

-

Fuel:

-

pneumatic

Quick Details

-

Application:

-

Automotive Industry, Commercial Buildings, Developing World Water Solutions, Drinking water treatment, Food and Beverage Industry, Industrial Utilities, Irrigation and Agriculture, Marine, Metal and Equipment Manufacturers, Mining industry, Pharmaceutical industry, Water Distribution

-

Pressure:

-

High Pressure

-

Voltage:

-

220V

-

Warranty:

-

1 year

-

Brand Name:

-

SUNCENTER

-

Model Number:

-

DGG800

-

Place of Origin:

-

Guangdong, China

-

Usage:

-

Water

-

Power:

-

Pneumatic

-

Standard or Nonstandard:

-

Standard

-

Theory:

-

Reciprocating Pump

-

Max pressure:

-

10bar-6400 bar

-

Applicable test product:

-

pipes/hose/tube/guage/sensor/valves/cylinders

-

Power Supply:

-

Pneumatic(Air driven)

-

Certificate:

-

ISO9001:2008

-

Fuel:

-

pneumatic

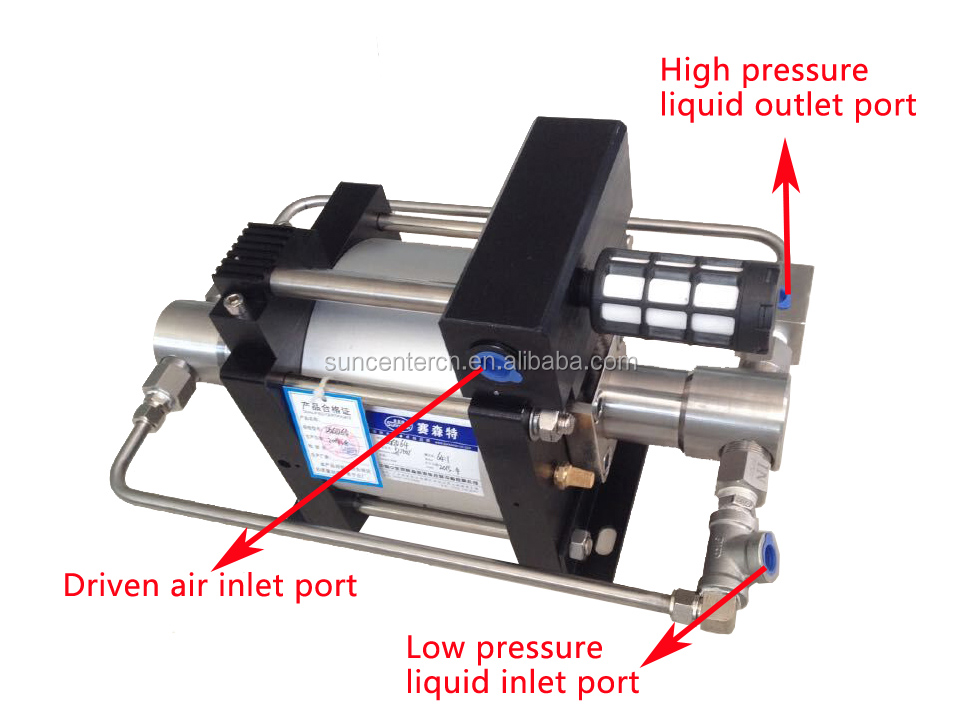

Air Driven Liquid Pump

MOQ:1 Set

Brand Name:SUNCENTER

Certificate:ISO/CE/SGS

Warranty:13 Months

Packaging:by Plywood case

Shipping Port: Shenzhen/Hongkong

Payment: T/T,Western Union,Credit card.

Transaction method:EXW,FOB,DDP,CIF,CFR

Place of Origin:Guangdong Province, China (Mainland)

Delivery Time:Within 10-15 working days after received deposit.

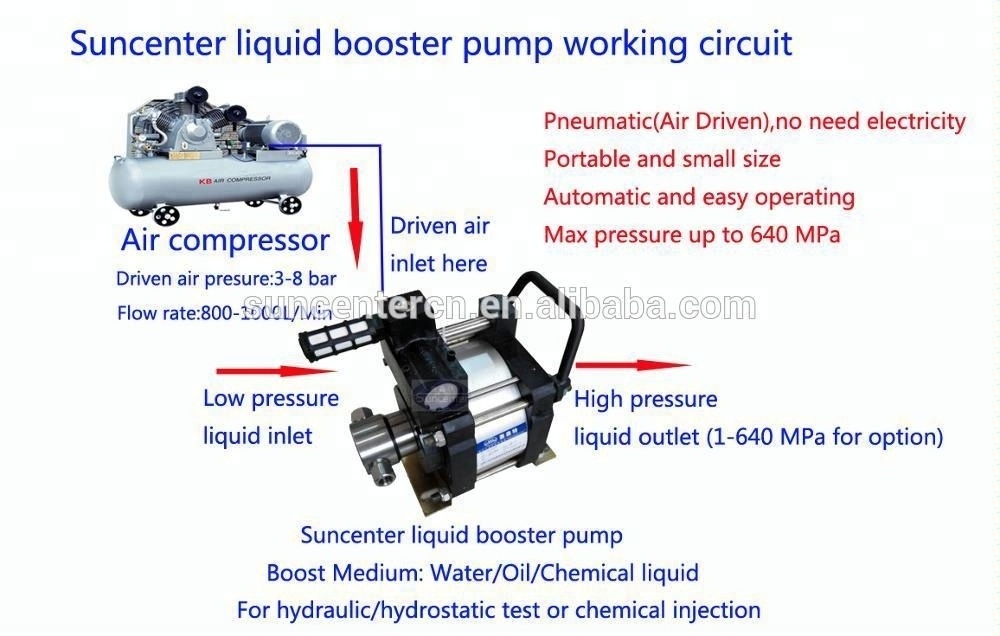

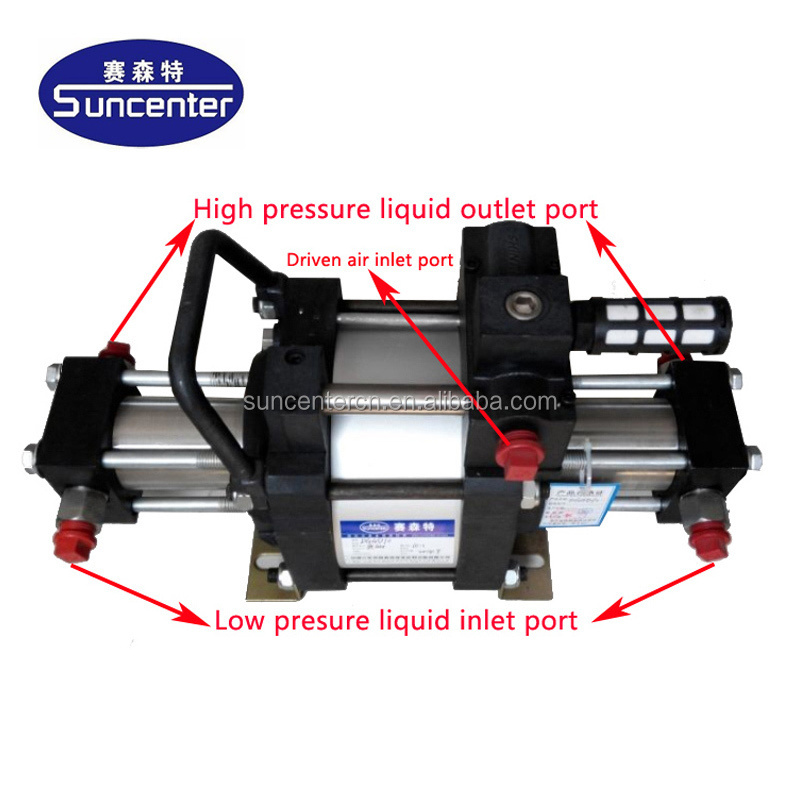

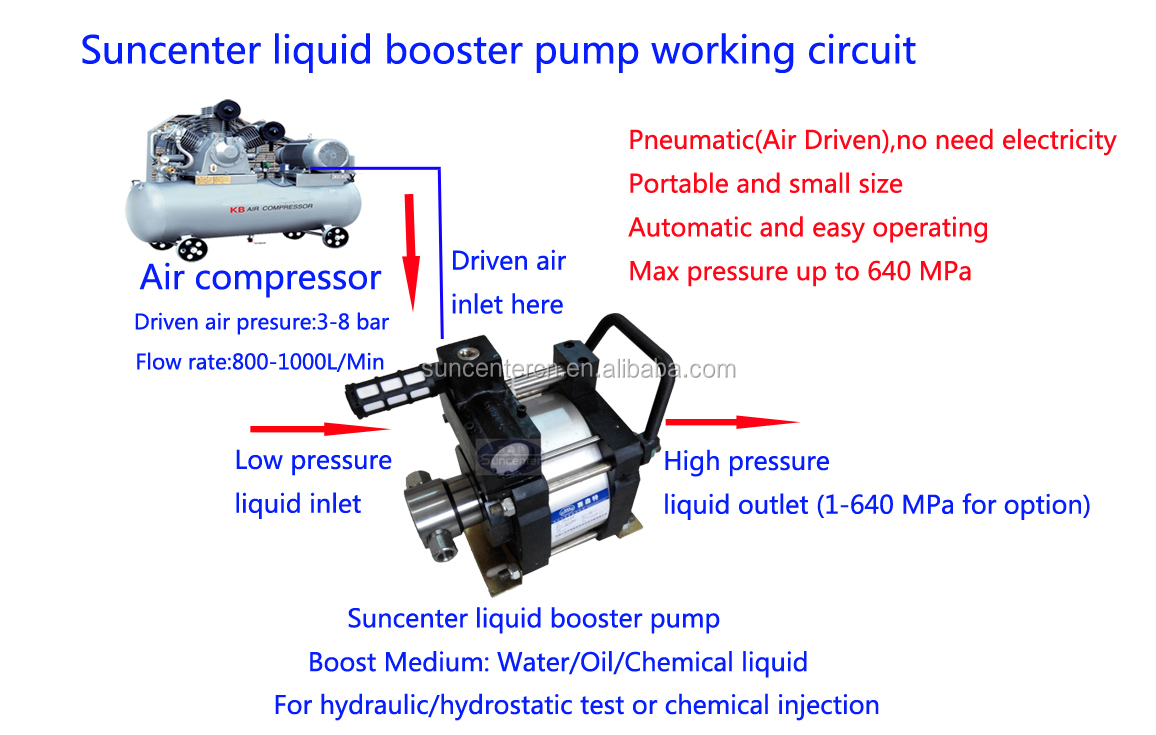

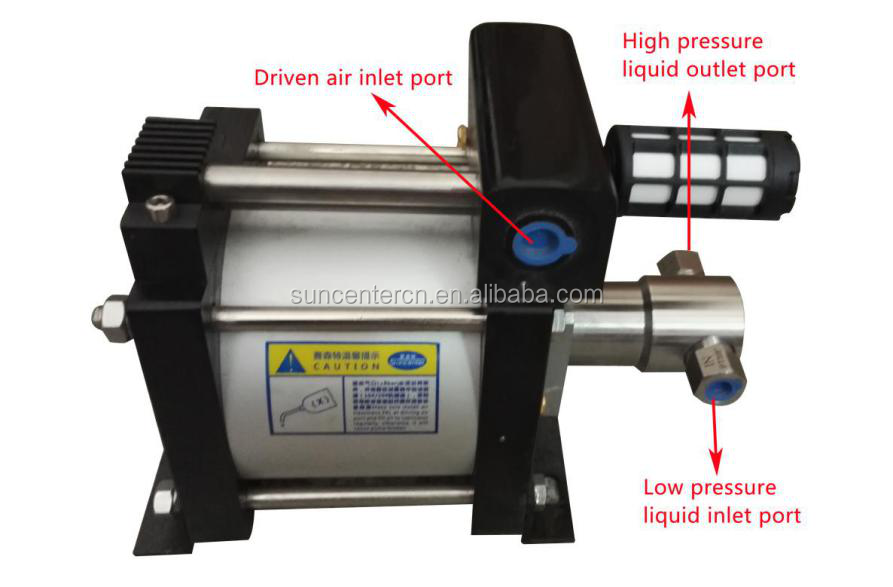

Compressed Air Driven Liquid Booster Pump-DGM/DGG/DGGD Series

We offer the most complete range of Air driven liquid pump models in the industry measured for:

A. Capability of ultimate pressure, flow or output horsepower.

B. Compatibility with a broad variety of liquids, such as oil, water and chemical applications.

SUNCENTER pumps are air driven at a drive air pressure of 1bar to 8bar (14.5 psi to116 psi) by the normal air compressor. Basically the principle of operation is similar to a reciprocating amplifier where control of the piston at the end position is regulated by a pilot operated 4/2 way valve.

Suncenter pumps feature a large air piston joint to a smaller diameter plunger. The pressure ratio is the difference of these two areas and is the method of determining maximum outlet pressure. Higher pressures obtained by using higher pressure ratios.Suncenter model numbers reflect the pumps nominal pressure ratios, while the technical data indicates exact ratios. The outlet pressure is easily to set through a simple air regulator. By multiplying the pressure ratio by the available shop air pressure, the nominal liquid pressure can be calculated.

SUNCENTER pumps are self priming. In general it is not necessary to use an air line lubricator.

The liquid to be pumped flows into the suction chamber by the up-stroke of the drive piston. By this suction effect, the inlet check valve is opened and the outlet check valve is closed. The down-stroke generates the pressure at the liquid side. The inlet check valve is closed and the outlet check valve is opened by the generated pressure. SUNCENTER liquid pumps cycle automatically, where the pressure is built up the numbers of cycles slow down, the pump stops automatically when the output pressure forces are equal. The pump restarts with a slight drop in the outlet pressure or an increase in the air drive pressure. Pump performance can be affected by a number of conditions, such as freezing of muffler or pilot valves (which is caused by moisture in air lines), inadequate inlet air line sizes and dirty filers. Don’t reduce the indicated port sizes and consult SUNCENTER for exact flow conditions not shown in charts.

Applications include:

Pressure testing

Burst(Hydrostatic) testing

Work holding/power clamping

Jacking/lifting

Valve actuator control

Hydraulic cylinder actuation

Press safety overload devices

Roller tensioning

Metering

Precision lubrication and spraying

Liquefied gas transfer

Key features include:

Compressed Air driven - no electricity required (connect to normal air compressor)

In order to extend the lifetime of the pump, the driving air pressure should

not be higher than 8 bar

No airline lubricator required

Pressures to 640Mpa (6400 bar)

Wide range of models with different ratios

Built-in-cooling on most models

Easy to install, operate and maintain

Best price / performance ratio

No heat, flame or spark risk and explosion proof

Automatic pressure holding, whatever the cause of the pressure drop, the Suncenter pump will automatically start, keep the loop pressure constant

DGM Series Liquid Pumps(Single acting, single air drive head)

They have aluminum bodies, with oxidation treatment and wetted materials of carbon steel or stainless steel, which depending on different service liquid. Material of stainless steel, making them an excellent choice of water application.

Portable design.

High quality seals, long service life available

Easy to install, operate and maintenance.

Explosion proof and no electrical power required.

|

Model

|

Pressure Boost Ratio

|

Driven air pressure PL

|

Formula to calculate outlet pressure

|

MAX Outlet

Pressure(bar)* |

Liquid inlet Connection

|

Liquid outlet Connection

|

MaxFlow rate(L/min)**

|

|

DGM1

|

1:1

|

2-8 bar

|

1XPL

|

8

|

NPT1

|

NPT1/2

|

20.50

|

|

DGM4

|

4:1

|

2-8 bar

|

4XPL

|

32

|

NPT1

|

NPT1/2

|

15.36

|

|

DGM10

|

10:1

|

2-8 bar

|

10XPL

|

80

|

NPT3/4

|

NPT1/2

|

7.15

|

|

DGM16

|

16:1

|

2-8 bar

|

16XPL

|

128

|

NPT /2

|

NPT 1/2

|

4.59

|

|

DGM30

|

30:1

|

2-8 bar

|

30XPL

|

240

|

NPT 1/2

|

NPT 3/8

|

2.53

|

|

DGM44

|

44:1

|

2-8 bar

|

44XPL

|

352

|

NPT 3/8

|

NPT 3/8

|

1.41

|

|

DGM64

|

64:1

|

2-8 bar

|

64XPL

|

512

|

NPT 3/8

|

NPT 3/8

|

0.95

|

|

DGM100

|

100:1

|

2-8 bar

|

100XPL

|

800

|

NPT 3/8

|

NPT 3/8

|

0.64

|

|

DGM170

|

170:1

|

2-8 bar

|

170XPL

|

1360

|

NPT 3/8

|

M14*1.5

|

0.37

|

|

Model

|

Pressure Boost Ratio

|

Driven air pressure PL

|

Formula to calculate outlet pressure

|

MAX Outlet

Pressure(bar)* |

Liquid inlet Connection

|

Liquid outlet Connection

|

MAX Flow (L/min)

|

|

DGG6

|

6:1

|

2-8 bar

|

6XPL

|

48

|

NPT1/2

|

NPT1/2

|

29.91

|

|

DGG10

|

10:1

|

2-8 bar

|

10XPL

|

80

|

NPT1/2

|

NPT1/2

|

18.84

|

|

DGG16

|

16:1

|

2-8 bar

|

16XPL

|

128

|

NPT1/2

|

NPT1/2

|

12.42

|

|

DGG28

|

28:1

|

2-8 bar

|

28XPL

|

224

|

NPT1/2

|

NPT1/2

|

7.11

|

|

DGG40

|

40:1

|

2-8 bar

|

40XPL

|

320

|

NPT1/2

|

NPT1/2

|

4.89

|

|

DGG64

|

64:1

|

2-8 bar

|

64XPL

|

512

|

NPT1/2

|

NPT3/8

|

3.08

|

|

DGG80

|

80:1

|

2-8 bar

|

80XPL

|

640

|

NPT1/2

|

NPT3/8

|

2.44

|

|

DGG100

|

100:1

|

2-8 bar

|

100XPL

|

800

|

NPT1/2

|

NPT3/8

|

1.92

|

|

DGG130

|

130:1

|

2-8 bar

|

130XPL

|

1040

|

NPT1/2

|

M14X1.5

|

1.47

|

|

DGG175

|

175:1

|

2-8 bar

|

175XPL

|

1400

|

NPT3/8

|

M14X1.5

|

1.14

|

|

DGG255

|

255:1

|

2-8 bar

|

255XPL

|

2040

|

NPT1/4

|

M14X1.5

|

0.75

|

|

DGG400

|

400:1

|

2-8 bar

|

400XPL

|

3200

|

NPT1/4

|

M14X1.5

|

0.48

|

|

DGG510

|

510:1

|

2-8 bar

|

510XPL

|

4080

|

NPT1/4

|

M14X1.5

|

0.65

|

|

DGG800

|

800:1

|

2-8 bar

|

800XPL

|

6400

|

NPT1/4

|

M14X1.5

|

0.42

|

The outlet liquid pressure=Driven air pressure*boost ratio

In order to extend the lifetime of the pump, the driving air pressure should not be higher than 8 bar

DGGD Series Liquid Pumps(Double acting, single air drive head)

They are characterized by the same features as the DGG pumps single acting, single air drive head types,

but they have less pulsations and deliver approx. 50 % more flow.

|

Model

|

Pressure Boost Ratio

|

Driven air pressure PL

|

Formula to calculate outlet pressure

|

MAX Outlet

Pressure(bar)* |

Liquid inlet Connection

|

Liquid outlet Connection

|

MAX Flow (L/min)**

|

|

DGGD4

|

4:1

|

2-8 bar

|

4XPL

|

32

|

NPT1/2

|

NPT1/2

|

70.00

|

|

DGGD6

|

6:1

|

2-8 bar

|

6XPL

|

48

|

NPT1/2

|

NPT1/2

|

48.60

|

|

DGGD10

|

10:1

|

2-8 bar

|

10XPL

|

80

|

NPT1/2

|

NPT1/2

|

30.61

|

|

DGGD16

|

16:1

|

2-8 bar

|

16XPL

|

128

|

NPT1/2

|

NPT1/2

|

19.73

|

|

DGGD28

|

28:1

|

2-8 bar

|

28XPL

|

224

|

NPT1/2

|

NPT1/2

|

11.30

|

|

DGGD40

|

40:1

|

2-8 bar

|

40XPL

|

320

|

NPT1/2

|

NPT3/8

|

7.69

|

|

DGGD64

|

64:1

|

2-8 bar

|

64XPL

|

512

|

NPT1/2

|

NPT3/8

|

4.94

|

|

DGGD80

|

80:1

|

2-8 bar

|

80XPL

|

640

|

NPT1/2

|

NPT3/8

|

3.96

|

|

DGGD100

|

100:1

|

2-8 bar

|

100XPL

|

800

|

NPT1/2

|

NPT3/8

|

3.13

|

|

DGGD130

|

130:1

|

2-8 bar

|

130XPL

|

1040

|

NPT1/2

|

M14*1.5

|

2.40

|

|

DGGD175

|

175:1

|

2-8 bar

|

175XPL

|

1400

|

NPT3/8

|

M14*1.5

|

1.81

|

|

DGGD255

|

255:1

|

2-8 bar

|

255XPL

|

2040

|

NPT1/4

|

M14*1.5

|

1.23

|

|

DGGD400

|

400:1

|

2-8 bar

|

400XPL

|

3200

|

NPT1/4

|

M14*1.5

|

0.79

|

The outlet liquid pressure=Driven air pressure*boost ratio

In order to extend the lifetime of the pump, the driving air pressure should not be higher than 8 bar

How to Select Suncenter Air Driven Liquid Boosters/Systems?

In order to choose suitable liquid booster pump or systems for you,

please kindly reply us the following questions:

1.What is the liquid you want to booster?

2. What outlet liquid pressure do you want?( )bar

3. What driven air pressure (of your air compressor) can you offer?( )bar,

Because our booster is completely air operated and no need any electricity

4. What outlet liquid flow rate do you need?( )L/min

Packing&Shipping

Package: pack in plywood case Shipment: by air/sea/express

Company Introduction

Dongguan Suncenter Fluid Control Equipment Co., Ltd

is the member company of Suncenter Group, which is located in Dongguan city of Guangdong province in China. With more than 15 years experiences in fluid pressure exchange and controlling field, we provide various kinds of pneumatic and hydraulic booster pumps, systems and solutions to the customers all over the world. Due to our best product quality, competitive price as well as excellent after-sales service, we have win a great reputation in the field.

Our main products including:

1. High Pressure Booster Pumps ( Gas Booster Pump, Air Driven Liquid Pump, Air Amplifiers)

2. High Pressure Systems (Gas/Liquid Booster System,Hydro test bench,Chemical injection system,CO2/FM200 filling machine, Tube Expanding Machine)

3. High Pressure Test Equipment(Hydraulic/Burst/Hydrostatic test machine,Cylinder test machine, Valve test bench,Impulse Testing Machine, etc.)

4. Hydro-pneumatic cylinders and machines(pneumatic hydraulic cylinders,pneumatic riveting machines,pneumatic press machines etc.)

Customer review

Certification

Our Advantages

-1. 15 years of manufacturing experience history.

-2. faster lead time, the fastest delivery is about 5-10 working days.

-3. CE & SGS certificate approval factory.

-4. Quality control for every step while production.

-5. Professional engineers have working experience in Maximator.

FAQ

Q: Are you factory?

A: Yes, we have more than 15 years experiences in high pressure fluid exchange and controlling field,we provide various kinds of pneumatic and hydraulic boosters,systems and solutions.

Q: Where's your location? can I visit you?

A: Welcome to visit Suncenter, we are in Dongguan City, Guangdong province, China.

Q: How to operate the machine?

A: After you get the machine, we will send you the working video to teach you for maintenance and

operating.

Q: How long is your warranty?

A: 13 months.

Hot Searches