- Product Details

- {{item.text}}

Quick Details

-

Heating method:

-

Steam or electricity

-

After-sales Service Provided:

-

Service Machinery Overseas

-

Usage:

-

Produce cream, gel, lotion, shampoo etc

-

Material:

-

SUS 304/316L

-

Place of Origin:

-

GuangZhou China (Mainland)

-

Application:

-

Cosmetic Production

-

Mixing speed:

-

0-80 R/M

-

Speed of homogenizer:

-

0~3500rpm

-

Market:

-

Around the world

Quick Details

-

Brand Name:

-

LIENM

-

Type:

-

Cosmetic making machine, fixed typy

-

Marketing Type:

-

New Product 2021

-

Heating method:

-

Steam or electricity

-

After-sales Service Provided:

-

Service Machinery Overseas

-

Usage:

-

Produce cream, gel, lotion, shampoo etc

-

Material:

-

SUS 304/316L

-

Place of Origin:

-

GuangZhou China (Mainland)

-

Application:

-

Cosmetic Production

-

Mixing speed:

-

0-80 R/M

-

Speed of homogenizer:

-

0~3500rpm

-

Market:

-

Around the world

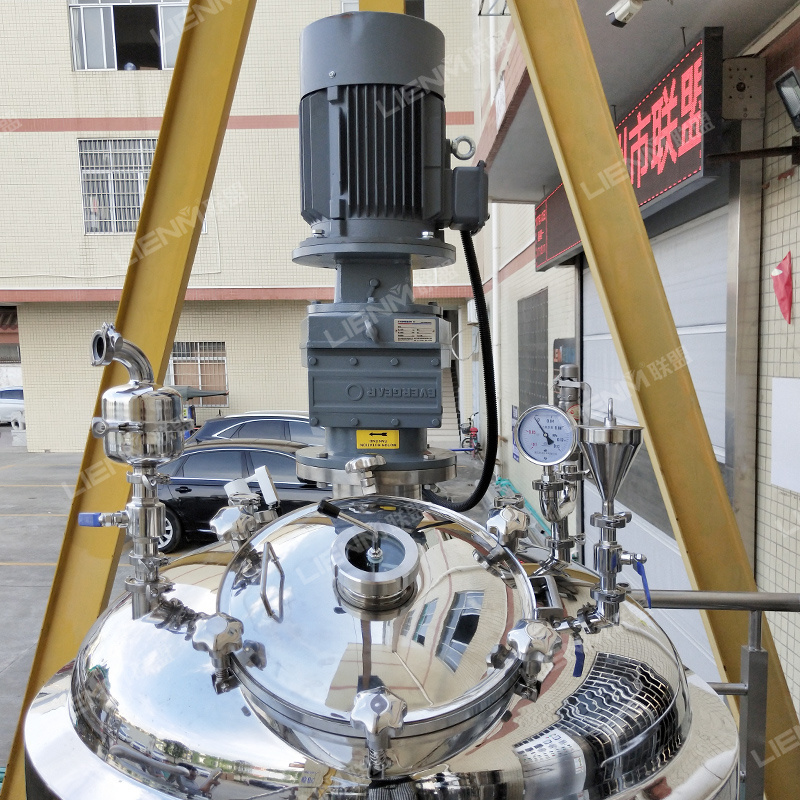

150L Cosmetics manufacturing equipment snail slime machine emulsifier snail slime extractor cosmetic cream making machine

Product Description

Introduction

1, LIENM Fixed type internal and external Emulsifier Homogenizer Mixer for Cosmetic Manufacturing,which can meet different technological demands.

2, The homogenizing structure is made through German technology. The machine adopts the imported double-end mechanical seal effect.The maximum emulsifying rotation speed can reach 3500 rpm and the high shearing fineness can reach 0.2-5 um.

3, The vacuum defoaming can make the materials meet the requirement of being aseptic . The vacuum materials vacuum sucking can avoid dust.

4, The main boiler lid can adopt lifting system, it is easy to clean and the cleaning effect is more obvious, the main boiler can adopt tilting discharge.

5, The boiler body is welded with 3 layer imported SS plate, tank body and pipes adopts mirror polish which meet the GMP standard.

6, According to process requirement, the tank body can heating and cooling the electric heating.

7, To ensure the stability of whole machine, the machine adopt the imported electric appliances which can meet the international standards.

2, The homogenizing structure is made through German technology. The machine adopts the imported double-end mechanical seal effect.The maximum emulsifying rotation speed can reach 3500 rpm and the high shearing fineness can reach 0.2-5 um.

3, The vacuum defoaming can make the materials meet the requirement of being aseptic . The vacuum materials vacuum sucking can avoid dust.

4, The main boiler lid can adopt lifting system, it is easy to clean and the cleaning effect is more obvious, the main boiler can adopt tilting discharge.

5, The boiler body is welded with 3 layer imported SS plate, tank body and pipes adopts mirror polish which meet the GMP standard.

6, According to process requirement, the tank body can heating and cooling the electric heating.

7, To ensure the stability of whole machine, the machine adopt the imported electric appliances which can meet the international standards.

|

Product

|

Vacuum Homogenizer Emulsifier Cream Lotion Mixing Tank Lipstick Making Machine

|

|

Type

|

Fixed type

|

|

Heating method

|

Steam or electricity

|

|

Control

|

Manual or by touch screen

|

|

Product capacity

|

50L-2T, customized

|

|

Model

|

Working

|

Mixing

|

|

Homogenizing

|

|

Heating way

|

||

|

|

capacity

|

Power

|

Speed

|

Power

|

Speed

|

Suggestion

|

||

|

LM-S-ZRG-A-10L

|

10L

|

0.75kw

|

0-63rpm

|

3kw

|

0-3550rpm

|

Electric heating

|

||

|

LM-S-ZRG-A-20L

|

20L

|

0.75kw

|

|

3kw

|

|

|

||

|

LM-S-ZRG-A-50L

|

50L

|

0.7kw

|

|

3kw

|

|

|

||

|

LM-S-ZRG-A-100L

|

100L

|

1.5kw

|

|

4kw

|

|

Electric or steam heating

|

||

|

LM-S-ZRG-A-200L

|

200L

|

2.2kw

|

|

5.5kw

|

|

Electric or steam heating

|

||

|

LM-S-ZRG-A-300L

|

300L

|

3kw

|

|

7.5kw

|

|

Electric or steam heating

|

||

|

LM-S-ZRG-A-500L

|

500L

|

4kw

|

|

11kw

|

|

Electric or steam heating

|

||

|

LM-S-ZRG-A-1000L

|

1000L

|

5.5kw

|

|

15kw

|

|

Steam heating

|

||

|

LM-S-ZRG-A-2000L

|

2000L

|

5.5kw

|

|

18.5kw

|

|

Steam heating

|

||

|

LM-S-ZRG-A-3000L

|

3000L

|

11kw

|

|

22kw

|

|

Steam heating

|

||

Our Service

Product Category

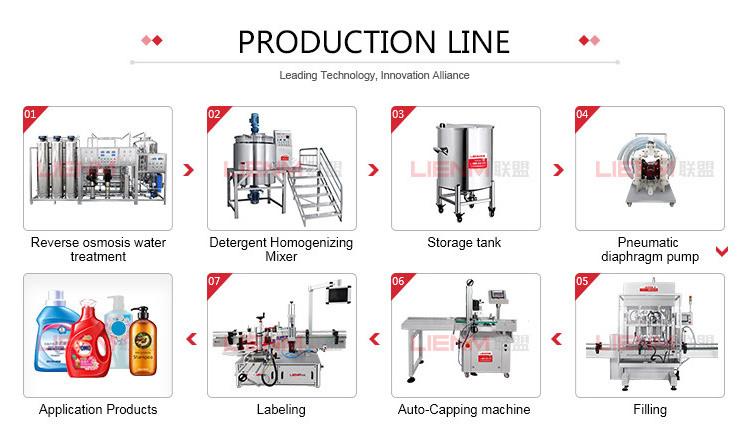

LIENM Fixed type internal and external Emulsifier Homogenizer Mixer for Cosmetic Manufacturing, Face Cream Making Machine composed of pretreating boilers, vacuum emulsifying and blending boiler, hydraulic lifting system, dumping system, electric control system and work platform etc.

LIENM Fixed type internal and external Emulsifier Homogenizer Mixer for Cosmetic Manufacturing, Face Cream Making Machine composed of pretreating boilers, vacuum emulsifying and blending boiler, hydraulic lifting system, dumping system, electric control system and work platform etc.

Product packaging

FAQ

1. Why choose us?

1.1- We have over 30 years experience on machinery making .

1.2- Our factory is located in Guangzhou and another one is in Jiangsu province,more than 200 workers in our factory .

1.3- We sale good quality machines around the world with good service and got high reputation from our customer. Welcome to visit our factory!

2.Can you customize machine ?

As a professional machinery manufacturer for more than 30 years,we have skilled OEM technique.

3. What about after sale service?

Engineer will go to buyer's factory to install, test machines, and train buyer's staff how to operate, maintain machines.

When machine has problem, We will solve basic questions by telephone, email, whatsapp, wechat and video call.

Customers showing us the picture or video of the problem. If the problem can be easily solved , we will send you solution by video or pictures. If the problem out of your control, we will arrange engineer to your factory.

4.How about warranty and spare parts?

We provide 1 year warranty and enough spare parts for the machine,and most of the parts can be found in local market also,also you can buy from us if all the parts that over than 1 year warranty.

5. How can you control the quality and delivery?

All our machines will be tested before packaging. Teaching video and packing pictures will be sent to you for checking,we promise that our wooden packaging is strong enough and safety for long delivery .

6. What about the delivery time?

In stock machine:1-7days

Usually 7-60 Working days(depened on products).

1.1- We have over 30 years experience on machinery making .

1.2- Our factory is located in Guangzhou and another one is in Jiangsu province,more than 200 workers in our factory .

1.3- We sale good quality machines around the world with good service and got high reputation from our customer. Welcome to visit our factory!

2.Can you customize machine ?

As a professional machinery manufacturer for more than 30 years,we have skilled OEM technique.

3. What about after sale service?

Engineer will go to buyer's factory to install, test machines, and train buyer's staff how to operate, maintain machines.

When machine has problem, We will solve basic questions by telephone, email, whatsapp, wechat and video call.

Customers showing us the picture or video of the problem. If the problem can be easily solved , we will send you solution by video or pictures. If the problem out of your control, we will arrange engineer to your factory.

4.How about warranty and spare parts?

We provide 1 year warranty and enough spare parts for the machine,and most of the parts can be found in local market also,also you can buy from us if all the parts that over than 1 year warranty.

5. How can you control the quality and delivery?

All our machines will be tested before packaging. Teaching video and packing pictures will be sent to you for checking,we promise that our wooden packaging is strong enough and safety for long delivery .

6. What about the delivery time?

In stock machine:1-7days

Usually 7-60 Working days(depened on products).

Recommend Products

Hot Searches