- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

LS-100FY

-

Place of Origin:

-

Jiangsu, China

-

Model:

-

LS-100LD

-

Volume:

-

100L

-

Voltage:

-

220v

-

Power:

-

4.5KW

-

Working pressure:

-

0.22MPa

-

Timer:

-

1-60min

-

Working temperature:

-

135℃

-

boiling temperature:

-

≤100℃

Quick Details

-

Warranty:

-

1 Year

-

After-sale Service:

-

Online technical support

-

Brand Name:

-

JIBIMED

-

Model Number:

-

LS-100FY

-

Place of Origin:

-

Jiangsu, China

-

Model:

-

LS-100LD

-

Volume:

-

100L

-

Voltage:

-

220v

-

Power:

-

4.5KW

-

Working pressure:

-

0.22MPa

-

Timer:

-

1-60min

-

Working temperature:

-

135℃

-

boiling temperature:

-

≤100℃

Product Description

100L retort sterilization machine sterilizer for food/can/plastic bottle/pouches autoclave

LS-35LD, LS-50LD, LS-75LD, LS-100LD, LS-120LD, LS-150LD counter pressure sterilizer is microcomputer-program -controlled,which is

adopts electric heating method. The water is directly injected into the sterilization chamber to heat, and generates the

high-pressure steam required for sterilization purpose. After the sterilization is finished, the compressed air is externally

supplied for proceed the cooling for 3 minutes, the temperature inside would lower 30~40℃. The sterilizer is designed to perform

both boiling sterilization and rapid cooling pressure sterilization. The boiling range is set at ≤100 °C. The rapid cooling

pressure sterilization range temperature is pre-selected from 105 ° C to 134 ° C. The heating tubes are provided with overload

protection ,and the buzzer would alarm to indicate the sterilizing end. It is easy to operate, safe and reliable, which is

suitable for disinfection and sterilization of food packaging and utensils, equipment and other items and especially suitable

applying in food research institutes for sterility testing.

adopts electric heating method. The water is directly injected into the sterilization chamber to heat, and generates the

high-pressure steam required for sterilization purpose. After the sterilization is finished, the compressed air is externally

supplied for proceed the cooling for 3 minutes, the temperature inside would lower 30~40℃. The sterilizer is designed to perform

both boiling sterilization and rapid cooling pressure sterilization. The boiling range is set at ≤100 °C. The rapid cooling

pressure sterilization range temperature is pre-selected from 105 ° C to 134 ° C. The heating tubes are provided with overload

protection ,and the buzzer would alarm to indicate the sterilizing end. It is easy to operate, safe and reliable, which is

suitable for disinfection and sterilization of food packaging and utensils, equipment and other items and especially suitable

applying in food research institutes for sterility testing.

Product Paramenters

2 BASIC PARAMETER

|

MODEL

|

Chamber size(L)

|

Rating working pressure

(MPa) |

Rating working temperature(℃)

|

Rating input consumption(kW)

|

timer(min)

|

Pressure(mpa)/

Temperature(℃) range (MPa/℃) |

DIMENSION

(CM) |

G.W/N.W(kg)

|

|

LS-35FY

|

35

|

0.22

|

134

|

1×2.5

|

0~99

|

0.07~0.22/

105~134 |

48×46×85

|

56/42

|

|

LS-50FY

|

50

|

|

|

2×1.5

|

|

|

52×52×98

|

65/55

|

|

LS-75FY

|

75

|

|

|

3×1.5

|

|

|

56×56×98

|

90/70

|

|

LS-100FY

|

100

|

|

|

|

|

|

59×59×108

|

105/85

|

|

LS-120FY

|

120

|

|

|

3×2

|

|

|

60×64×114

|

125/100

|

|

LS-150FY

|

150

|

|

|

|

|

|

67×69×114

|

135/110

|

3 CHARACTERISTICS

a) Equipped with a pressure/temperature controller, the pressure setting range is 0.07 to 0.22MPa (corresponding to a saturated

steam temperature of 115 to 134°C).

b) Equipped with safety valve, by the sterilizing pressure exceed the allowable figure, which would release the pressure

automatically.

c) Equipped with immersed heating tube, with anti-dry function, while the water is in low level, the unit would cut off the power

to stop the heating and alarm.

a) Equipped with a pressure/temperature controller, the pressure setting range is 0.07 to 0.22MPa (corresponding to a saturated

steam temperature of 115 to 134°C).

b) Equipped with safety valve, by the sterilizing pressure exceed the allowable figure, which would release the pressure

automatically.

c) Equipped with immersed heating tube, with anti-dry function, while the water is in low level, the unit would cut off the power

to stop the heating and alarm.

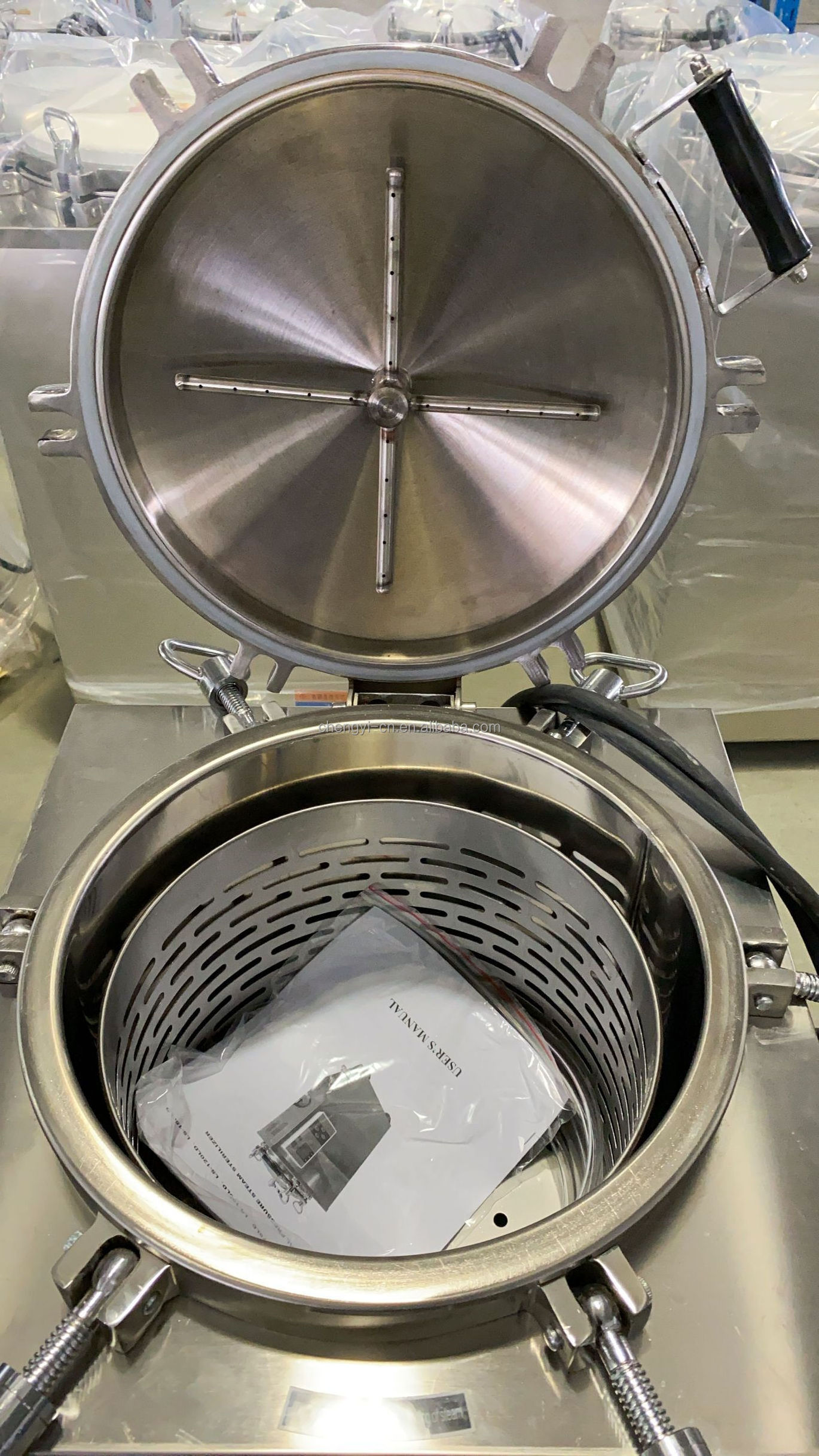

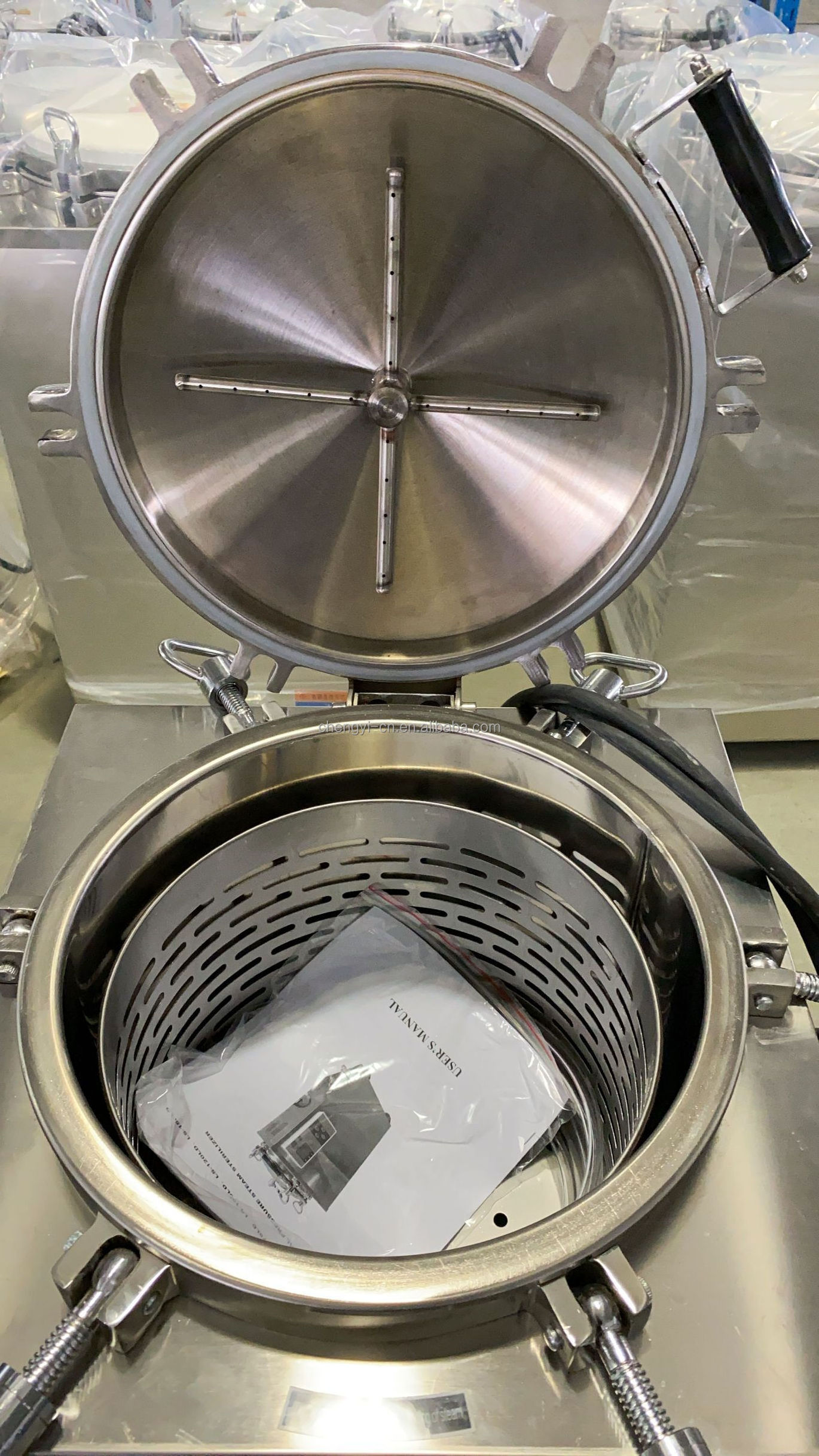

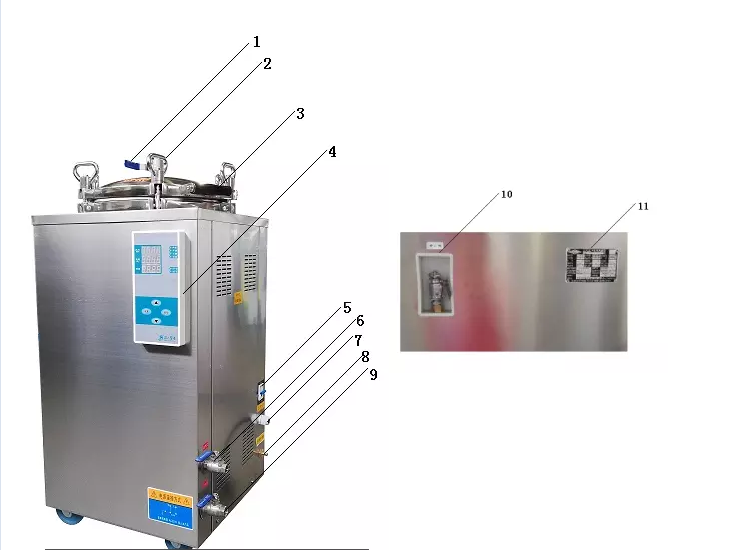

4 CONSTRUCTION

1. Inlet faucet 2. Tighten bolts 3. Handle 4. Control panel 5. breaker switch 6. Air inlet 7. Power cord

8. exhaust port 9. water outlet 10. safety valve 11. nameplate

(Pic 1 CONSTRUCTION)

5 WORKING PRINCIPLE

This product is designed for two kinds of disinfection and sterilization:. Direct heating to produces pressured steam. Then the

pressure steam acts on the microorganisms to destroy its structure then achieve sterilization purposes. For the rapid cooling and

sterilization procedure, firstly injected 6 liters tap water into the chamber, and then heat for about 25 minutes to proceed the

sterilization and at the meanwhile the temperature inside in maintained. The sterilization time is 35-40 minutes. After the

completion, 0.24MPa-compressed air is manually injected into the chamber, and then the drain valve is 1/2 opened for drainage, for

those soft packages are counter pressured cooled. Quickly cooling for 3 minutes, manually turn off the entering of the compressed

air and tap water, the temperature of the objects in the chamber can be lowered to 30 ~ 40 °C.

This product is designed for two kinds of disinfection and sterilization:. Direct heating to produces pressured steam. Then the

pressure steam acts on the microorganisms to destroy its structure then achieve sterilization purposes. For the rapid cooling and

sterilization procedure, firstly injected 6 liters tap water into the chamber, and then heat for about 25 minutes to proceed the

sterilization and at the meanwhile the temperature inside in maintained. The sterilization time is 35-40 minutes. After the

completion, 0.24MPa-compressed air is manually injected into the chamber, and then the drain valve is 1/2 opened for drainage, for

those soft packages are counter pressured cooled. Quickly cooling for 3 minutes, manually turn off the entering of the compressed

air and tap water, the temperature of the objects in the chamber can be lowered to 30 ~ 40 °C.

Certifications

Hot Searches