- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V or 380V

-

Dimension(L*W*H):

-

1130x750x1890mm

-

Motor Power (kW):

-

1.5

-

Model Number:

-

J23-16T

-

Weight (T):

-

2

-

Norminal pressure stroke:

-

5mm

-

Slide stroke:

-

60mm

-

Slide stroke times:

-

140 Times/min

-

Max closing height:

-

170mm

-

Die height adjustment:

-

40mm

-

Distance between slider center machine:

-

160mm

-

Pole distance:

-

220mm

-

Pad thickness:

-

50mm

-

Body tilting angle:

-

30°

-

Item:

-

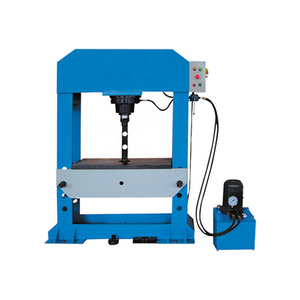

stamping steel mould crankshaft sheet metal c type 10 ton power press

Quick Details

-

Slide Stroke (mm):

-

80

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

BLMA

-

Voltage:

-

220V or 380V

-

Dimension(L*W*H):

-

1130x750x1890mm

-

Motor Power (kW):

-

1.5

-

Model Number:

-

J23-16T

-

Weight (T):

-

2

-

Norminal pressure stroke:

-

5mm

-

Slide stroke:

-

60mm

-

Slide stroke times:

-

140 Times/min

-

Max closing height:

-

170mm

-

Die height adjustment:

-

40mm

-

Distance between slider center machine:

-

160mm

-

Pole distance:

-

220mm

-

Pad thickness:

-

50mm

-

Body tilting angle:

-

30°

-

Item:

-

stamping steel mould crankshaft sheet metal c type 10 ton power press

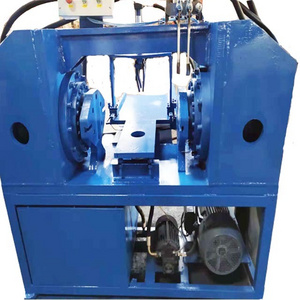

250 Tons 300 Ton 500T CNC Automatic Press Wheel Barrow

Hydraulic Power Press

The power press is for cutting, punching, blanking, bending and light stretching work 1. C- frame provides maximum rigidity and min deflection for accurate parts and long tool life.Steel-welded frame, high rigidity and less deformation Compact.Thick plates and large columns provide you with the stable platform you need for your demanding application. 2. Wide body frame eliminating vibration for improved ide life and machine,which means economical and practical. Operation space is wide, and the movable bolster could be moved out of frame to set the die. The structure is simple and the appliance is also beautiful. 3. High accuracy, high efficiency, simple and convenient operation, good performance, favorable price and best service.

Specification

Specification

|

Item

|

Unit

|

16T

|

||

|

Norminal capacity

|

KN

|

160

|

||

|

Norminal pressure stroke

|

mm

|

5

|

||

|

Slide stroke

|

mm

|

60

|

||

|

Slide stroke times

|

Times/min

|

140

|

||

|

Max closing height

|

mm

|

170

|

||

|

Die height adjustment

|

mm

|

40

|

||

|

Distance between slider center and machine

|

mm

|

160

|

||

|

Workbench size

|

Front and back

|

mm

|

300

|

|

|

Left and right

|

mm

|

480

|

||

|

Diameter of blank-holding hole

|

Front and back

|

mm

|

110

|

|

|

Left and right

|

mm

|

220

|

||

|

Diamater

|

mm

|

160

|

||

|

Pole distance

|

mm

|

220

|

||

|

Slider underside bore

|

Front and back

|

mm

|

180

|

|

|

Left and right

|

mm

|

200

|

||

|

Size of die handel bore

|

Diammeter

|

mm

|

35

|

|

|

Depth

|

mm

|

60

|

||

|

Pad thickness

|

mm

|

50

|

||

|

Body tilting angle

|

°

|

30

|

||

|

Motor power

|

KW

|

1.5

|

||

|

Dimension

|

mm

|

1130x750x1890

|

||

Product Description

Product Description

Intergrally forged frame, never deformation.

Adopts crankshaft-type structure, the crankshaft is made by 45# forged steel, significantly improving the crankshaft service life. All copper tile is used reduce the operation friction and wear to improve the machine service life.

Forged steel gear with good wear-resistant property and longer service life.

Brake belt is made by 16Mn material and equipped with friction block for providing reliable and controllable brake force, and with good hydraulic transmission and cooling capacity to avoid hydraulic failure and recession caused by overheat.

Equipped with left and right safety guard to ensure the operator's safety.

Manually adjusts the die height of mechanical punch, scale display

Use France Schneider electrics to ensure the machine service life.

Use Germany Siemens motor to ensure the operation reliability.

Controlling the electromagnet and machine by pedal switch, which is easy operated.

Both-hands operation buttons to ensure the operators' safety.

Manual centralized lubrication. Simple and easy operation.

Flat cutting

Positioning ruler on the worktable can control the cutting shape and cutting length with higher accuracy. The ironworker can cut small flat sheets. This function is same with shearing machine.

FAQ

FAQ

1.Are you factory or trading company?

We are factory in an industrial town near Nanjing city.

2.What shall we do if don't know how to operate your machine?

We can arrange our engineers to your country and you can also send your engineers to our factory for learning operation. Besides,

There are detailed installation and operating instructions attached. It's very simple, we have telephone and Email support at

24hours per day.

3.What are your payment terms?

We support T/T, L/C, Western Union and so on. Other ways can also be accepted after we both sides' discussion and agreement.

We are factory in an industrial town near Nanjing city.

2.What shall we do if don't know how to operate your machine?

We can arrange our engineers to your country and you can also send your engineers to our factory for learning operation. Besides,

There are detailed installation and operating instructions attached. It's very simple, we have telephone and Email support at

24hours per day.

3.What are your payment terms?

We support T/T, L/C, Western Union and so on. Other ways can also be accepted after we both sides' discussion and agreement.

Hot Searches