- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

ROMAS

-

Product Name:

-

LED Lamp Holder Die-casting aluminum parts

-

Size:

-

Customized Size

-

Lighting solutions service:

-

Lighting and circuitry design

-

Light Source:

-

LED

-

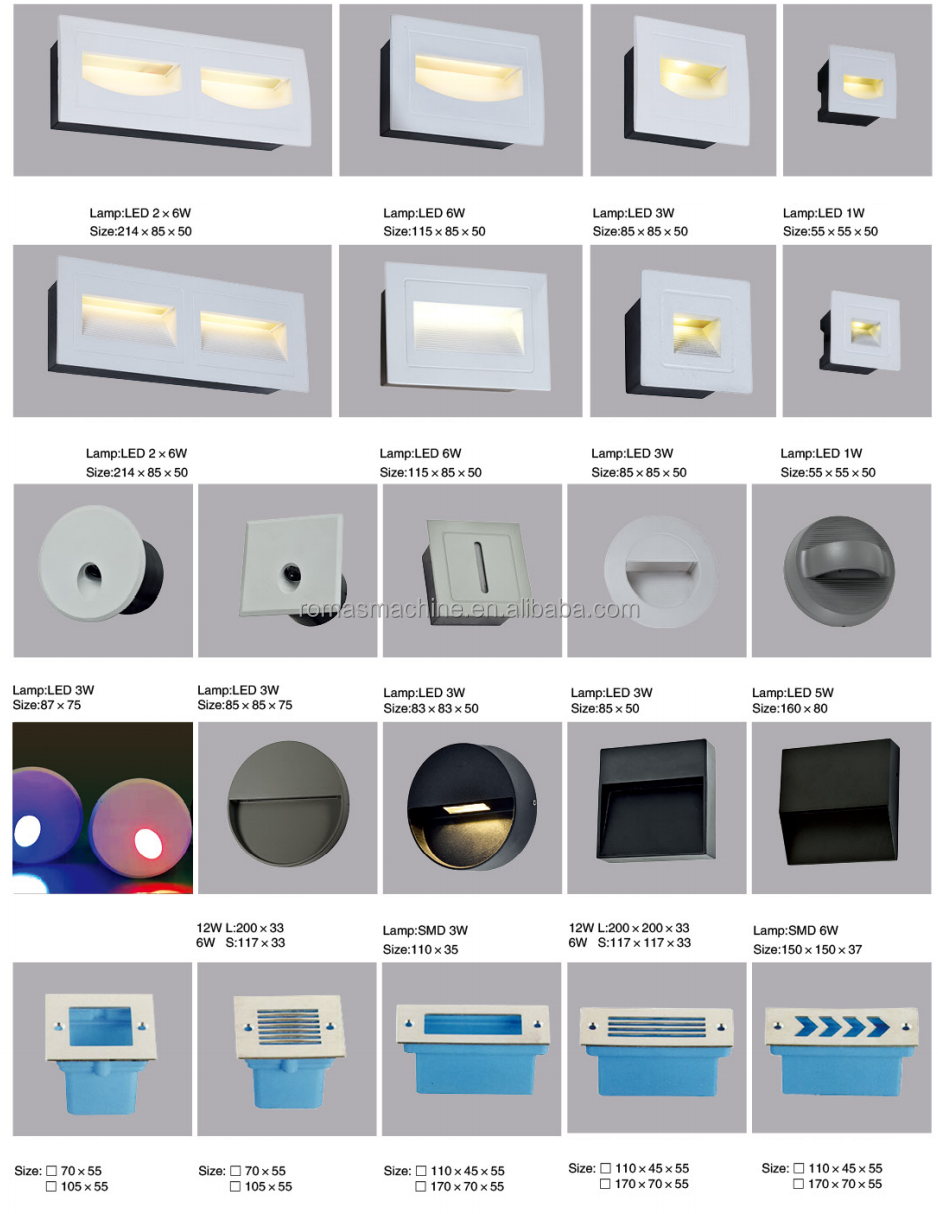

Shape:

-

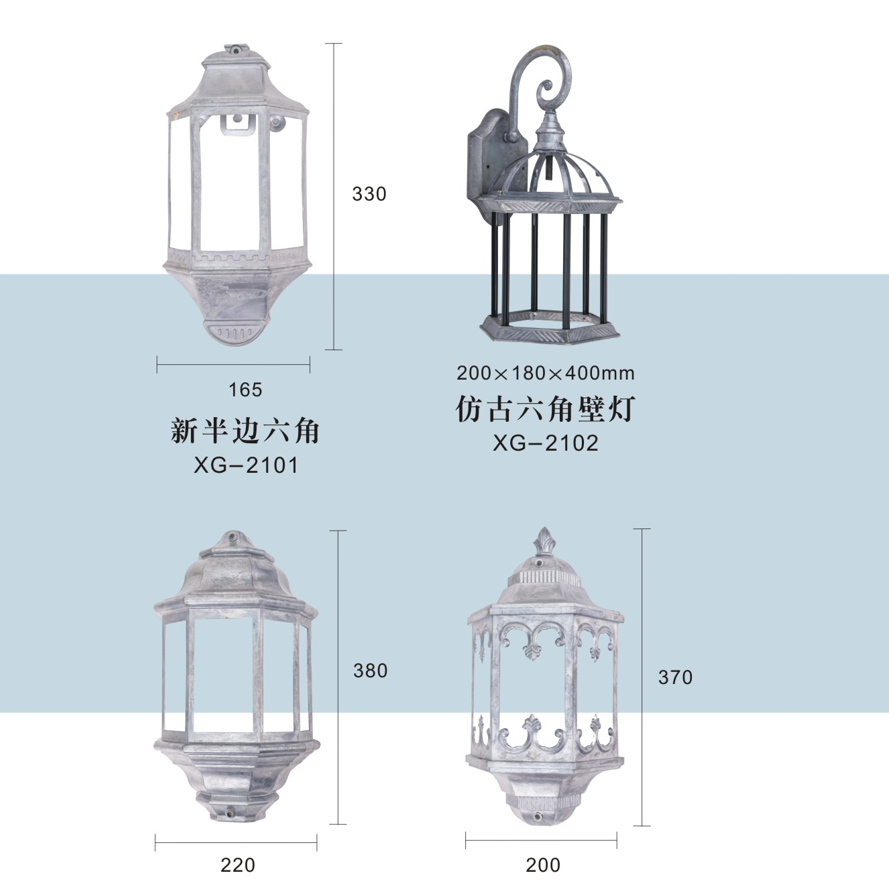

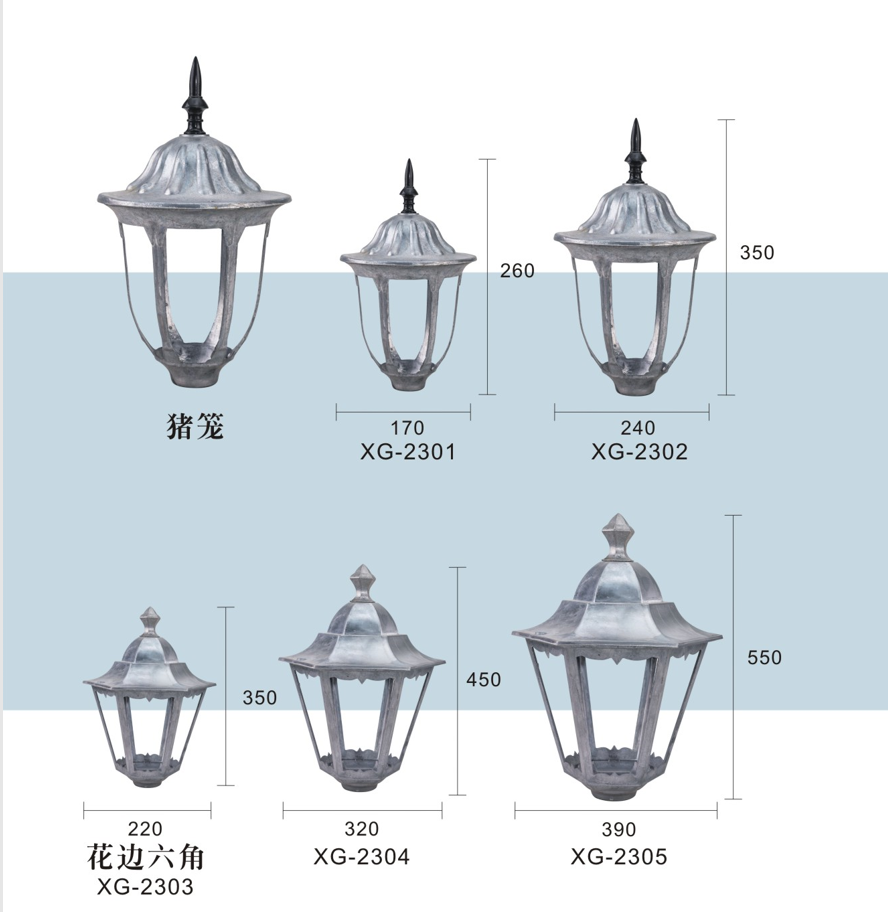

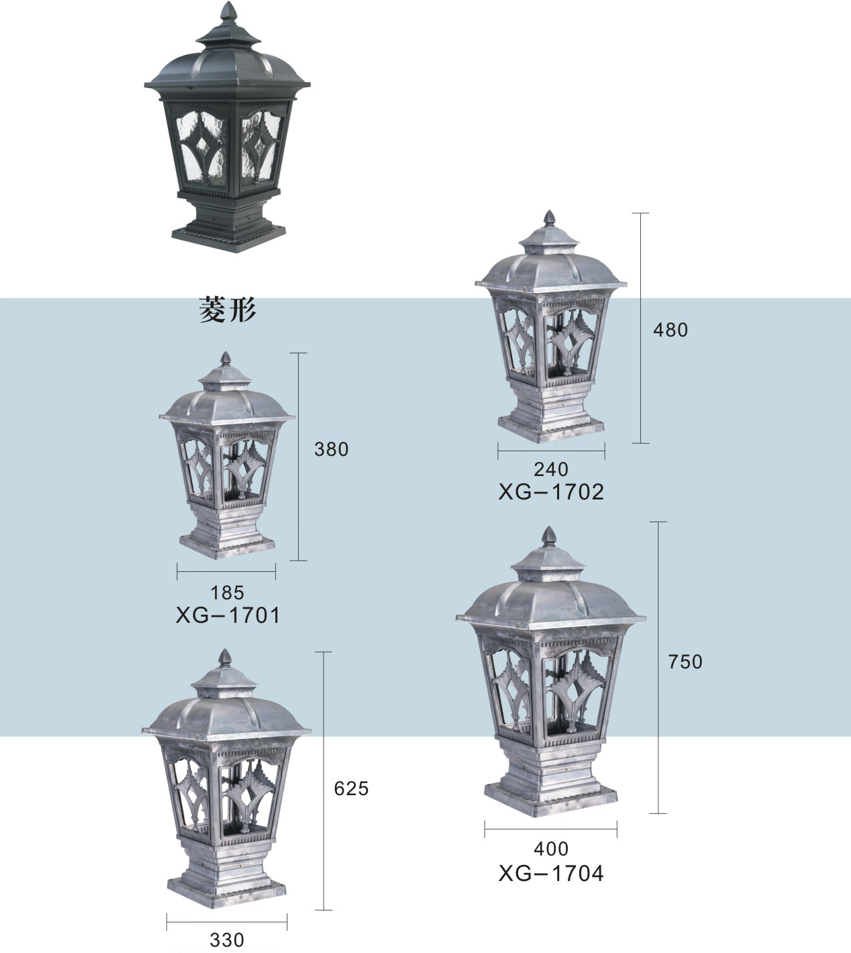

Round Oval Square Rectangular

-

MOQ:

-

100 Pcs

-

Package:

-

Standard Carton

-

Design:

-

Accept OEM

-

Payment:

-

T/T: 30% Deposit

Quick Details

-

Material:

-

Die-casting aluminum

-

Warranty(Year):

-

1-Year

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

ROMAS

-

Product Name:

-

LED Lamp Holder Die-casting aluminum parts

-

Size:

-

Customized Size

-

Lighting solutions service:

-

Lighting and circuitry design

-

Light Source:

-

LED

-

Shape:

-

Round Oval Square Rectangular

-

MOQ:

-

100 Pcs

-

Package:

-

Standard Carton

-

Design:

-

Accept OEM

-

Payment:

-

T/T: 30% Deposit

Product Description

Specialized in manufacturing Aluminum die-casting parts for over 12 years

1.High machining accuracy, the flatness within 0.1mm.

2.High strength and not easy to deform, has good electrical and thermal conductivity.

3.High finish appearance, smooth surface roughness is Ra1.6 after machining.

Title goes here.

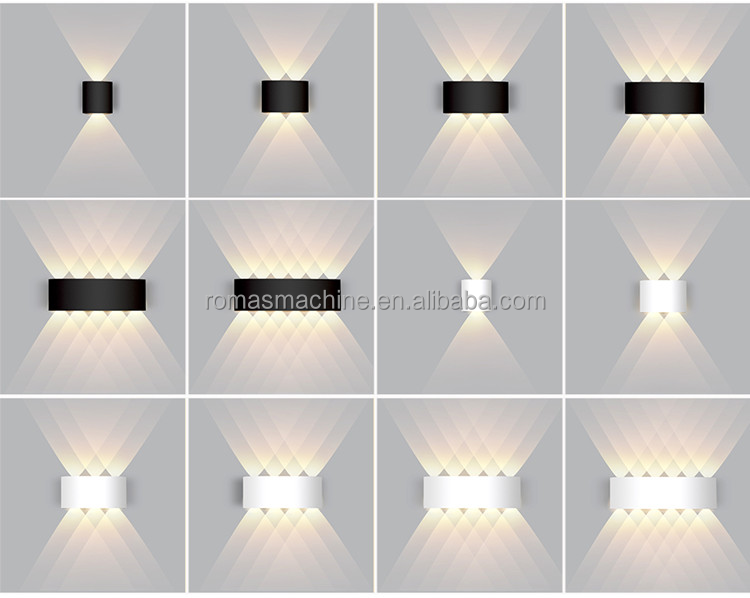

• Stamping steel housing, die-cast alum-alloy is optional for improving heat dispersion.

• Surface finished with powder coating, white & black color are available.

Detailed Images

Production Process

Double checked 2D / 3D drawing

Mold-making design ( flow design material gate/mold cavity )

Start to test mold and produce samples for customer checking

Powder coating

Deburring + Polishing

The aluminum die-casting process

Raw material ingot

CNC machining ( Do not powder coating for some assembly areas)

Finished products

CMM inspection + Customized package

Multiple Production Processes

1. Die Casting

2. Polishing

3. Deburring

4. Drilling

5. Tapping

6. CNC Machining

Surface Treatment

A1. Chemical oxidation

A2. Painting

A3. Electrophoresis

B1. Anodizing

B2. Sand blasting

B3. Electroplating

C1. Vibration Grinding

C2. Powder coating

C3. Non-stick coating

Product Presentation

|

Specification

|

Customized Light Aluminum Die Casting Parts

|

|

Material

|

Zinc,Magnesium,Aluminum,Alloy,Customize

|

|

Processing Craft

|

Drawings→ mould making → casting →rough machining → CNC machining→surface treatment →product checking→ packing →delivery

|

|

Application

|

Automobile, agricultural machinery, furniture,construction, home appliances, electronics.

|

|

Unit Weight

|

3g~40kgs

|

|

Dimensions

|

<=1500mm

|

|

Die Casting Machine Specification

|

80T-4000T

|

|

Surface Treatment

|

Mill-Finished, Powder Coating,Polishing, Brushing, etc.

|

|

Mold Making Time

|

Zinc alloy (10-15 days ),Aluminum alloy (12 -15 days)

|

|

Mould Life

|

50-500K shots

|

|

Drawing Format

|

IGES, STEP, AutoCAD, Solidworks, STL, PTC Creo, DWG, PDF, etc.

|

|

Quality Control

|

ISO/TS16949:2002 and ISO14001:2004 system

|

|

Service

|

Weekly report,Key node report,Any questions will be answered within 24 hours.

|

Packing&Shipping

FAQ

Q: Are you a manufacturer or trading company?

A: Most of the machines, molds and thermoforming products are made by ourselves. But the plastic raw material or auxiliary

equipment we can help customers buy it

Q: Can you make customized machines or products?

A: Yes, for the thermoforming products we can help the customer design it or send the 3D drawing to us. For the machines, just

tell me requirements, then we can make the machine meet them.

Q: If I send the plastic drawings to you, can you just make it for me and don't show it to anyone?

A: We are obliged to keep confidential or sign a confidentiality agreement with customers' products, except customers allowed

Q: Why should you Order from us, Not from other suppliers?

A: Specialized in manufacturing and selling Plastic Blowing machines with Professional service and High quality. Our technical

team has over 25 years of experience in the plastic machine field. We provide turn-key& tailor-made solutions.

Q: How to customize your products?

A: 1. Receive the samples or drawings from the client, or the client gives us the requirement.

2. Our engineer dept. to draw the 3D or 2D drawing, we can offer UG, Pro/E, Solidworks, CAD, and CAX... etc. drawing for the

client to check.

3. After the client confirms the drawings, we start to process the molds.

4. Test the molds, and send the sample to our client to check it. Or invite the client to our factory to check. Because we the

machine manufactory, we have a thermoforming machine to test the molds anytime.

5. If the client confirms the samples are OK, We can start Mass production. If not, we modify the mold to meet the client's

requirements.

Q: How about the delivery time

A: For the thermoforming machines, it's about 25-35 days.

For the thermoforming molds, it's about 25-35 days after confirming the drawings.

For the Lamp products, depending on the QTY of the order.

Q: Can I get the samples to check it?

A: Yes, We can send you the product styles to choose it, and we can provide some samples for your inspection for FREE. But you

need to pay the freight.

Q: What's your MOQ of products? Can I order a small QTY to check quality at first?

A: For machine and mold, the MOQ is 1 sets; And the customer can check the quality in our factory or warehouse

For Lamps, we can be sent your samples to check it. When you are satisfied with it, then you can place an order. And the MOQ is

dependent on different products.

Q: What services can we provide?

A: Accepted Delivery Terms: FOB, CFR, CIF, EXW;

Accepted Payment Currency: USD, EUR, AUD;

Accepted Payment Type: T/T, L/C, Credit Card, Western Union;

Language Spoken: English, Chinese, Spanish, Arabic, French, Russian...

Q: Can you offer oversea after-sales service for the machines?

A: First we will offer the English operation manual for every machine

Second, we can send the engineer to the customer's factory to train the workers on how to operate the machine. But the charge must

be paid by the customer third, if the simple machine, we can teach customers in our factory as free.

Q. What are your terms of payment?

A: T/T 40% as deposit, and 60% before delivery. We'll show you the photos of the products and packages before you pay the balance.

Q. Do you test all your goods before delivery?

A: Yes, we have 100% test before delivery

Q: How do you make our business long-term and good relationship?

A:1. We keep good quality and competitive price to ensure our customers benefit ;

2. We respect every customer as our friend and we sincerely do business and make friends with them, no matter where they come

from.

A: Most of the machines, molds and thermoforming products are made by ourselves. But the plastic raw material or auxiliary

equipment we can help customers buy it

Q: Can you make customized machines or products?

A: Yes, for the thermoforming products we can help the customer design it or send the 3D drawing to us. For the machines, just

tell me requirements, then we can make the machine meet them.

Q: If I send the plastic drawings to you, can you just make it for me and don't show it to anyone?

A: We are obliged to keep confidential or sign a confidentiality agreement with customers' products, except customers allowed

Q: Why should you Order from us, Not from other suppliers?

A: Specialized in manufacturing and selling Plastic Blowing machines with Professional service and High quality. Our technical

team has over 25 years of experience in the plastic machine field. We provide turn-key& tailor-made solutions.

Q: How to customize your products?

A: 1. Receive the samples or drawings from the client, or the client gives us the requirement.

2. Our engineer dept. to draw the 3D or 2D drawing, we can offer UG, Pro/E, Solidworks, CAD, and CAX... etc. drawing for the

client to check.

3. After the client confirms the drawings, we start to process the molds.

4. Test the molds, and send the sample to our client to check it. Or invite the client to our factory to check. Because we the

machine manufactory, we have a thermoforming machine to test the molds anytime.

5. If the client confirms the samples are OK, We can start Mass production. If not, we modify the mold to meet the client's

requirements.

Q: How about the delivery time

A: For the thermoforming machines, it's about 25-35 days.

For the thermoforming molds, it's about 25-35 days after confirming the drawings.

For the Lamp products, depending on the QTY of the order.

Q: Can I get the samples to check it?

A: Yes, We can send you the product styles to choose it, and we can provide some samples for your inspection for FREE. But you

need to pay the freight.

Q: What's your MOQ of products? Can I order a small QTY to check quality at first?

A: For machine and mold, the MOQ is 1 sets; And the customer can check the quality in our factory or warehouse

For Lamps, we can be sent your samples to check it. When you are satisfied with it, then you can place an order. And the MOQ is

dependent on different products.

Q: What services can we provide?

A: Accepted Delivery Terms: FOB, CFR, CIF, EXW;

Accepted Payment Currency: USD, EUR, AUD;

Accepted Payment Type: T/T, L/C, Credit Card, Western Union;

Language Spoken: English, Chinese, Spanish, Arabic, French, Russian...

Q: Can you offer oversea after-sales service for the machines?

A: First we will offer the English operation manual for every machine

Second, we can send the engineer to the customer's factory to train the workers on how to operate the machine. But the charge must

be paid by the customer third, if the simple machine, we can teach customers in our factory as free.

Q. What are your terms of payment?

A: T/T 40% as deposit, and 60% before delivery. We'll show you the photos of the products and packages before you pay the balance.

Q. Do you test all your goods before delivery?

A: Yes, we have 100% test before delivery

Q: How do you make our business long-term and good relationship?

A:1. We keep good quality and competitive price to ensure our customers benefit ;

2. We respect every customer as our friend and we sincerely do business and make friends with them, no matter where they come

from.

Hot Searches