- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

MEIDE

-

Model Number:

-

TC9 AB-3 BT20 GR8 GR12 GR23

-

Grade:

-

Titanium

-

weight:

-

D*D*3.542*L/1000000

-

Product name:

-

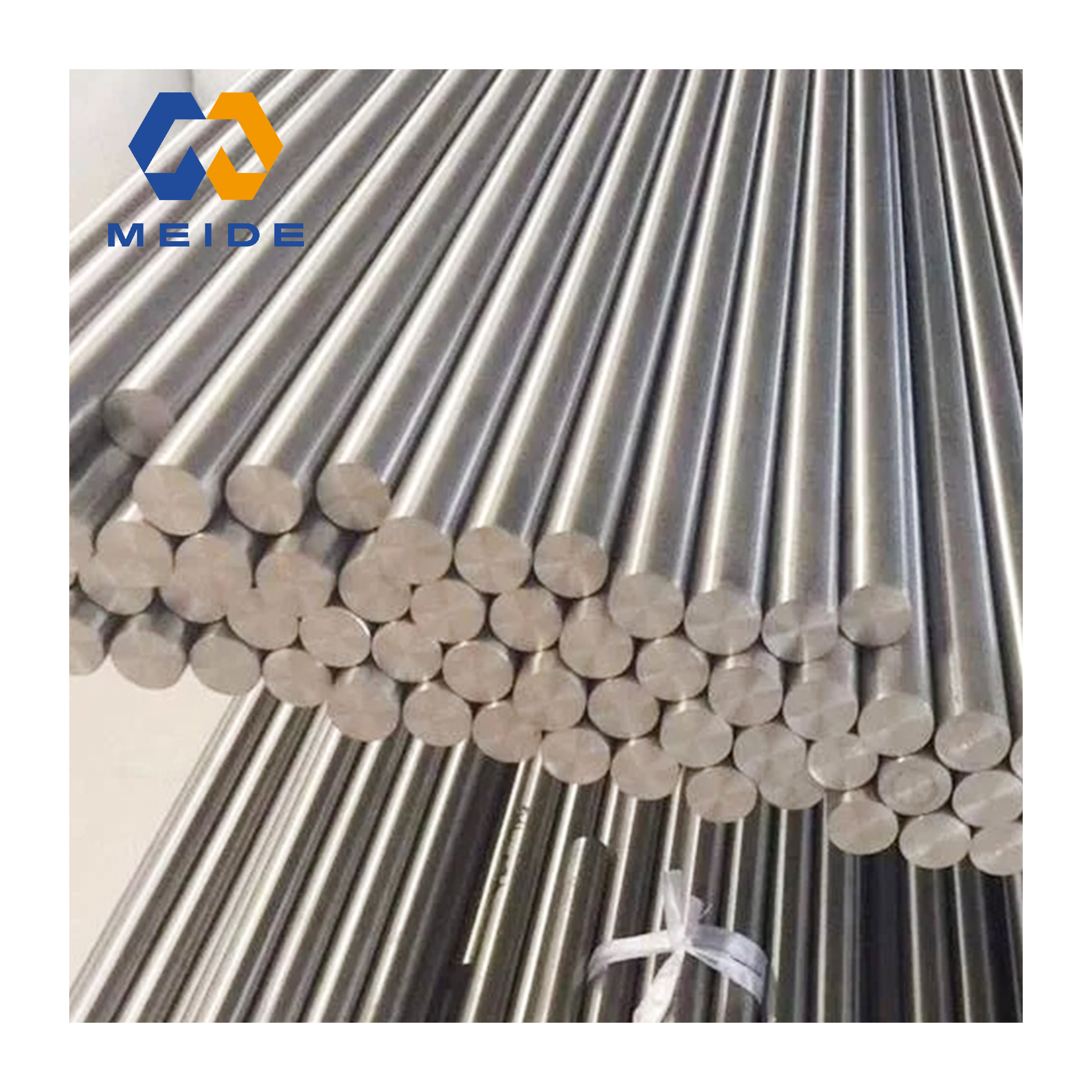

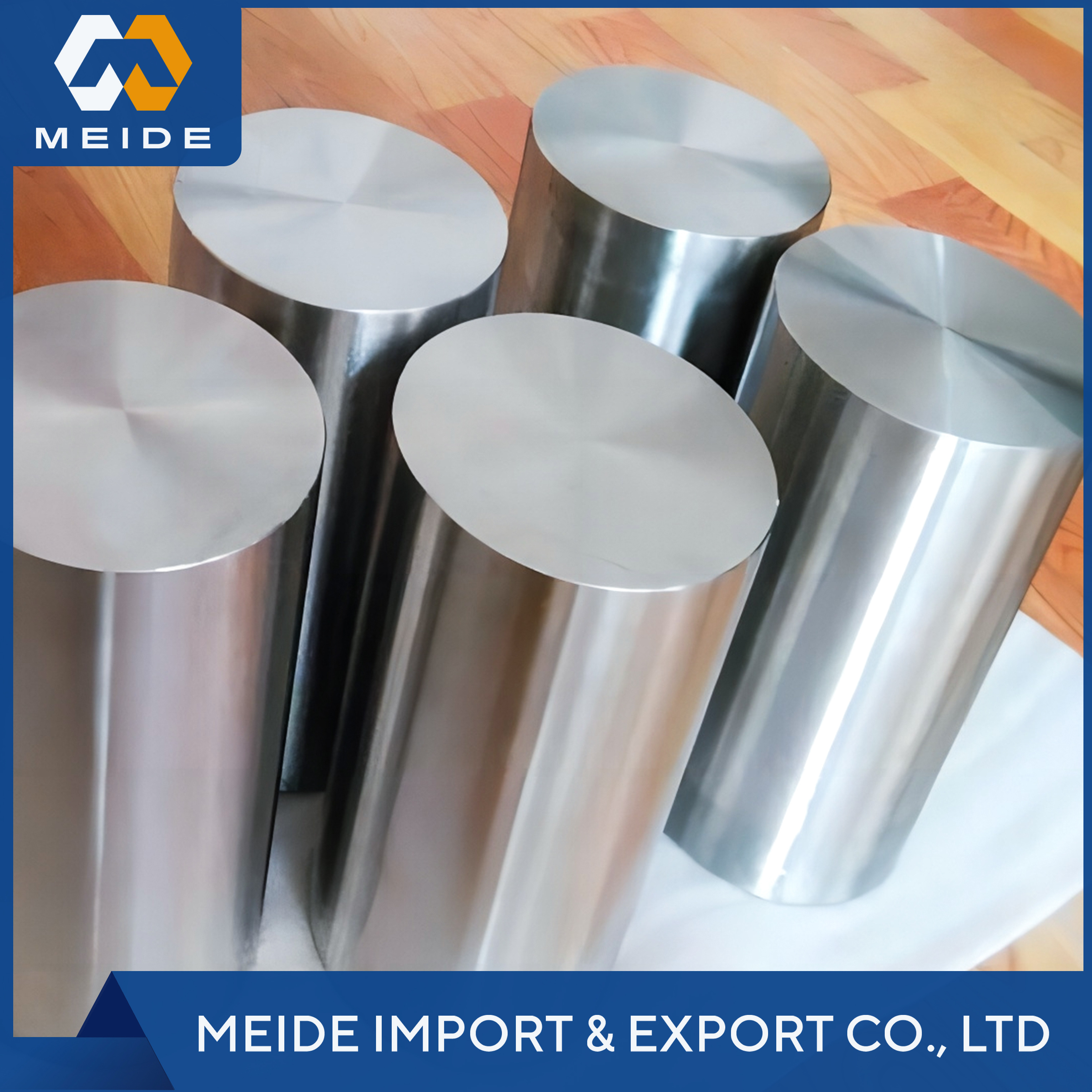

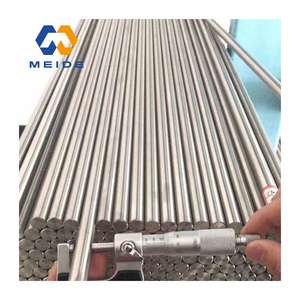

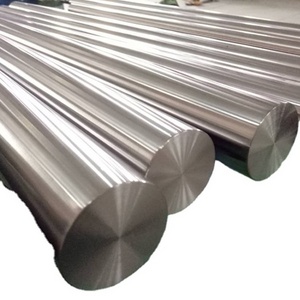

Titanium Alloy Rod/Bar

-

Keyword:

-

Titanium Round Bar/Rod

-

MOQ:

-

10 KG

-

Standard:

-

ASTM B348 ASTM F136

-

Material:

-

Titanium Gr1 Gr2 Gr5 Gr9 Gr10 Gr12

-

Processing:

-

hot rolled,cold rolled,forge,cold drawn

-

Surface:

-

Polished

-

diameter Tolerance1:

-

h6~h13

-

shape:

-

Round, flat, square, hexagonal

-

Advantage:

-

Corrosion Resistance

Quick Details

-

Application:

-

Industry, construction industry, medical industry, etc

-

Length:

-

MAX:6000mm

-

Technique:

-

Rolled

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

MEIDE

-

Model Number:

-

TC9 AB-3 BT20 GR8 GR12 GR23

-

Grade:

-

Titanium

-

weight:

-

D*D*3.542*L/1000000

-

Product name:

-

Titanium Alloy Rod/Bar

-

Keyword:

-

Titanium Round Bar/Rod

-

MOQ:

-

10 KG

-

Standard:

-

ASTM B348 ASTM F136

-

Material:

-

Titanium Gr1 Gr2 Gr5 Gr9 Gr10 Gr12

-

Processing:

-

hot rolled,cold rolled,forge,cold drawn

-

Surface:

-

Polished

-

diameter Tolerance1:

-

h6~h13

-

shape:

-

Round, flat, square, hexagonal

-

Advantage:

-

Corrosion Resistance

Product Introduction

Titanium Grade 1 is an unalloyed, low strength titanium product containing low oxygen with high formability; this titanium gradeis used in airframes, heat exchangers and desalination units.

Titanium Grade 2 is an unalloyed, medium strength titanium product. This titanium grade is used in airframes, aircraft engines and marine parts; good weldability and corrosion resistance are its distinguishing characteristics.

Titanium Grade 3 is an unalloyed, high strength, titanium product providing excellent corrosion resistance and good weldability. This titanium grade is primarily used in airframe and aircraft engine parts.

Titanium Grade 4 is the highest strength pure unalloyed titanium product. This titanium grade is used almost exclusively for airframe, aircraft engine parts, marine, surgical implants, hydraulic tubing. Good formability and corrosion resistance are its hallmark.

Titanium Grade 5 (6AL-4V)is an alloyed titanium product containing 6% Aluminum and 4% Vanadium; is a medium strength product. This titanium grade is predominantly used in airframe and turbine engine parts; and for use in surgical implants. Technical Info Titanium 6AL – 4V ELI is an alloyed titanium product containing 6% Aluminum and 4% Vanadium, ELI (Extra Low Interstitial).

6AL–2Sn–4Zr–2Mo (6-2-4-2)is an alloyed titanium product containing 6% Aluminum, 2% Tin, 4% Zirconium, 2% Molybdenum.

6AL–6V–2Sn (6-6-2)is an alloyed titanium product containing 6% Aluminum, 6% Vanadium, 2% Tin.

5AL–2.5Sn & ELI (5-2.5)is an alloyed titanium product containing 5% Aluminum and 2.5% Tin. Also ELI (Extra Low Interstitial).

8AL–1V–1Mo (8-1-1)is an alloyed titanium product containing 8% Aluminum, 1% Molybdenum and 1% Vanadium.

15V–3Cr–4AL–3Sn (15-3-4-3)is an alloyed titanium product containing 15% Vanadium, 3% Chromium, 4% Aluminum, 3% Tin.

Titanium Grade 2 is an unalloyed, medium strength titanium product. This titanium grade is used in airframes, aircraft engines and marine parts; good weldability and corrosion resistance are its distinguishing characteristics.

Titanium Grade 3 is an unalloyed, high strength, titanium product providing excellent corrosion resistance and good weldability. This titanium grade is primarily used in airframe and aircraft engine parts.

Titanium Grade 4 is the highest strength pure unalloyed titanium product. This titanium grade is used almost exclusively for airframe, aircraft engine parts, marine, surgical implants, hydraulic tubing. Good formability and corrosion resistance are its hallmark.

Titanium Grade 5 (6AL-4V)is an alloyed titanium product containing 6% Aluminum and 4% Vanadium; is a medium strength product. This titanium grade is predominantly used in airframe and turbine engine parts; and for use in surgical implants. Technical Info Titanium 6AL – 4V ELI is an alloyed titanium product containing 6% Aluminum and 4% Vanadium, ELI (Extra Low Interstitial).

6AL–2Sn–4Zr–2Mo (6-2-4-2)is an alloyed titanium product containing 6% Aluminum, 2% Tin, 4% Zirconium, 2% Molybdenum.

6AL–6V–2Sn (6-6-2)is an alloyed titanium product containing 6% Aluminum, 6% Vanadium, 2% Tin.

5AL–2.5Sn & ELI (5-2.5)is an alloyed titanium product containing 5% Aluminum and 2.5% Tin. Also ELI (Extra Low Interstitial).

8AL–1V–1Mo (8-1-1)is an alloyed titanium product containing 8% Aluminum, 1% Molybdenum and 1% Vanadium.

15V–3Cr–4AL–3Sn (15-3-4-3)is an alloyed titanium product containing 15% Vanadium, 3% Chromium, 4% Aluminum, 3% Tin.

Grade and Chemical Composition (%) :

|

Grade

|

N(≤)

|

C(≤)

|

H(≤)

|

Fe(≤)

|

O(≤)

|

Al(≤)

|

V(≤)

|

Ni(≤)

|

Ti

|

|

GR1

|

0.03

|

0.08

|

0.015

|

0.2

|

0.18

|

/

|

/

|

/

|

bal

|

|

GR2

|

0.03

|

0.08

|

0.015

|

0.3

|

0.25

|

/

|

/

|

/

|

bal

|

|

GR3

|

0.05

|

0.08

|

0.015

|

0.3

|

0.35

|

/

|

/

|

/

|

bal

|

|

GR4

|

0.05

|

0.08

|

0.015

|

0.2

|

0.4

|

/

|

/

|

/

|

bal

|

|

GR5

|

0.05

|

0.08

|

0.015

|

0.4

|

0.2

|

5.5~6.75

|

3.5~4.5

|

/

|

bal

|

|

GR7

|

0.03

|

0.08

|

0.015

|

0.3

|

0.25

|

/

|

/

|

/

|

bal

|

|

GR9

|

0.03

|

0.08

|

0.015

|

0.25

|

0.15

|

2.5~3.5

|

2.0~3.0

|

/

|

bal

|

|

GR12

|

0.03

|

0.08

|

0.015

|

0.3

|

0.25

|

/

|

/

|

0.6~0.9

|

bal

|

|

GR23

|

0.05

|

0.08

|

0.012

|

0.25

|

0.13

|

5.5~6.5

|

3.5~4.5

|

|

bal

|

Mechanical property

|

Grade

|

Tensil strength(≥)

|

|

Yeild strength(≥))

|

|

Elongation(≥)%)

|

||

|

|

ksi

|

Mpa

|

ksi

|

Mpa

|

|

||

|

GR1

|

35

|

240

|

20

|

138

|

24

|

||

|

GR2

|

50

|

345

|

40

|

275

|

20

|

||

|

GR3

|

65

|

450

|

55

|

380

|

18

|

||

|

GR4

|

80

|

550

|

70

|

483

|

15

|

||

|

GR5

|

130

|

895

|

120

|

828

|

10

|

||

|

GR7

|

50

|

345

|

40

|

275

|

20

|

||

|

GR9

|

90

|

620

|

70

|

483

|

15

|

||

|

GR12

|

70

|

483

|

20

|

345

|

18

|

||

|

GR23

|

120

|

828

|

110

|

760

|

10

|

||

Advantages of titanium rod

1.Light weight -[Specific gravity](60% of specific gravity of steel and about 1.7 times that of aluminum)

2.Low thermal expansion-[Hermal expansion coefficent](ne-half that of 18-8 stainless steel and one-third that of aluminum)

3.Low hear conductivity-[Heat conductivity](nearly the same as 18-8stainless steel)

4.Low electric conductivity-[Electric conductivity](about 3% of copper)

5.High flexibility-Longitudinal elastic modulus](one-half of iron or stainless steel and the same as copper)

6.Non-magnetism -[Magnetic permeability](non-magnetic material; magnetic permeability = 1.0001)

Titanium is 30% stronger than steel, but is nearly 50% lighter. Titanium is 60% heavier than aluminum, but twice as

strong.Titanium has excellent strength retention to 1,000 degrees Fahrenheit. Titanium is alloyed with aluminum, manganese, iron,molybdenum and other metals to increase strength, to withstand high temperatures, and to lighten the resultant alloy.Titanium’s high corrosion resistance is also a valuable characteristic; as when exposed to the atmosphere, titanium forms a tight,tenacious oxide film that resists many corrosive materials, particularly salt water.

2.Low thermal expansion-[Hermal expansion coefficent](ne-half that of 18-8 stainless steel and one-third that of aluminum)

3.Low hear conductivity-[Heat conductivity](nearly the same as 18-8stainless steel)

4.Low electric conductivity-[Electric conductivity](about 3% of copper)

5.High flexibility-Longitudinal elastic modulus](one-half of iron or stainless steel and the same as copper)

6.Non-magnetism -[Magnetic permeability](non-magnetic material; magnetic permeability = 1.0001)

Titanium is 30% stronger than steel, but is nearly 50% lighter. Titanium is 60% heavier than aluminum, but twice as

strong.Titanium has excellent strength retention to 1,000 degrees Fahrenheit. Titanium is alloyed with aluminum, manganese, iron,molybdenum and other metals to increase strength, to withstand high temperatures, and to lighten the resultant alloy.Titanium’s high corrosion resistance is also a valuable characteristic; as when exposed to the atmosphere, titanium forms a tight,tenacious oxide film that resists many corrosive materials, particularly salt water.

Product application

A

erospace Applications

Due to their high tensile strength to density ratio, high corrosion resistance, and ability to withstand moderately high

temperatures without creeping, titanium alloys are used in aircraft, armor plating, naval ships, spacecraft, and missiles.

Industrial Applications

Titanium is used in engine applications such as rotors, compressor blades, hydraulic system components and nacelles. Titanium 6AL-4V alloy accounts for almost 50% of all alloys used in aircraft applications.

Consumer and Architectural Applications

Titanium metal is used in automotive applications, particularly in automobile or motorcycle racing, where weight reduction is critical while maintaining high strength and rigidity.

Medical Applications

Due to their high tensile strength to density ratio, high corrosion resistance, and ability to withstand moderately high

temperatures without creeping, titanium alloys are used in aircraft, armor plating, naval ships, spacecraft, and missiles.

Industrial Applications

Titanium is used in engine applications such as rotors, compressor blades, hydraulic system components and nacelles. Titanium 6AL-4V alloy accounts for almost 50% of all alloys used in aircraft applications.

Consumer and Architectural Applications

Titanium metal is used in automotive applications, particularly in automobile or motorcycle racing, where weight reduction is critical while maintaining high strength and rigidity.

Medical Applications

Titanium has the inherent property to osseointegrate, enabling use in dental implants that can remain in place for over 30 years.

FAQ

1.Are you a manufacturer or a trader?

We're a manufacturer with more than years of professional production experience.

2.Can you accept OEM?

Yes, OEM is acceptable. Just pls provide us with the drawing or sample, we will production totally according to your requirements.

3.Can you provide us with the design drawing?

Yeah, of course, we will provide you with the drawing after you paid or prepaid.

4.Can your factory produce products according to our drawings?

Yes, we can. Most products can be customized, including the Logo on products.

5.What kind of your packaging?

Neutral plywood or wooden box packaging or according to customer's requirements.

6.How long is your delivery time?

Normally 30days after payment, and we promise we will deliver as soon as we can.

7.How can we get your price ?

1. We need below information to quote for you:

1). Product Name

2). Standard

3). Material Grade (Chemical Composition)

4). Dimension

5). Quantity

6). The Drawing for Special Parts

We're a manufacturer with more than years of professional production experience.

2.Can you accept OEM?

Yes, OEM is acceptable. Just pls provide us with the drawing or sample, we will production totally according to your requirements.

3.Can you provide us with the design drawing?

Yeah, of course, we will provide you with the drawing after you paid or prepaid.

4.Can your factory produce products according to our drawings?

Yes, we can. Most products can be customized, including the Logo on products.

5.What kind of your packaging?

Neutral plywood or wooden box packaging or according to customer's requirements.

6.How long is your delivery time?

Normally 30days after payment, and we promise we will deliver as soon as we can.

7.How can we get your price ?

1. We need below information to quote for you:

1). Product Name

2). Standard

3). Material Grade (Chemical Composition)

4). Dimension

5). Quantity

6). The Drawing for Special Parts

Hot Searches