This beverage mixer for the production of all kinds of carbonated beverage, (water, syrup, carbon dioxide) of carbonated proportions, such as lemon, cola, fruit juice and other soft drinks, beverage production line equipment is the main equipment. (In particular, the high-grade key beverage production equipment)

1 The machine with a chemical industry advanced technology - static mixer (ie carbonizer), its gas-liquid mass transfer area is large, small pressure loss, high efficiency, low energy consumption, simple structure, reliable performance and the use of noise small multi-stage centrifugal pumps, so that the whole performance is guaranteed.

2 Mixing ratio accurate, easy to adjust, the machine does not require replacement parts, you can easily yield and the ratio of syrup and water was adjusted.

3 Reflow machine uses carbon dioxide oxygen, carbon dioxide gas can save, but also to achieve the purpose of deoxy make deoxygenated water has a good pre-carbonization effect.

4 The machine easily adjust the air content, according to the requirements of beverage containing gas through proper operation and adjustment is completed.

5 The machine set up perfect automatic control system with motor coordination, simple structure, continuous production, automation features.

- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

99.9%

-

Voltage:

-

220V/380V

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

SKY

-

Dimension(L*W*H):

-

2400*1500*2300

-

Weight:

-

3500 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Capacity:

-

2000BPH~12000BPH

-

Bottle material:

-

Glass

-

Usage:

-

beer

-

Bottle size:

-

200ml-2000ml

-

Machine material:

-

304/316 S.S Material

-

Product name:

-

Soft Drink Bottling Plant

-

Control:

-

Electric control famous brand

-

Key word:

-

Carbonated Drink Filling Machine

-

Machine structure:

-

monoblock 3 in 1

Quick Details

-

Machinery Capacity:

-

2500BPH

-

Packaging Material:

-

Glass

-

Filling Material:

-

Beer

-

Filling Accuracy:

-

99.9%

-

Voltage:

-

220V/380V

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

SKY

-

Dimension(L*W*H):

-

2400*1500*2300

-

Weight:

-

3500 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Capacity:

-

2000BPH~12000BPH

-

Bottle material:

-

Glass

-

Usage:

-

beer

-

Bottle size:

-

200ml-2000ml

-

Machine material:

-

304/316 S.S Material

-

Product name:

-

Soft Drink Bottling Plant

-

Control:

-

Electric control famous brand

-

Key word:

-

Carbonated Drink Filling Machine

-

Machine structure:

-

monoblock 3 in 1

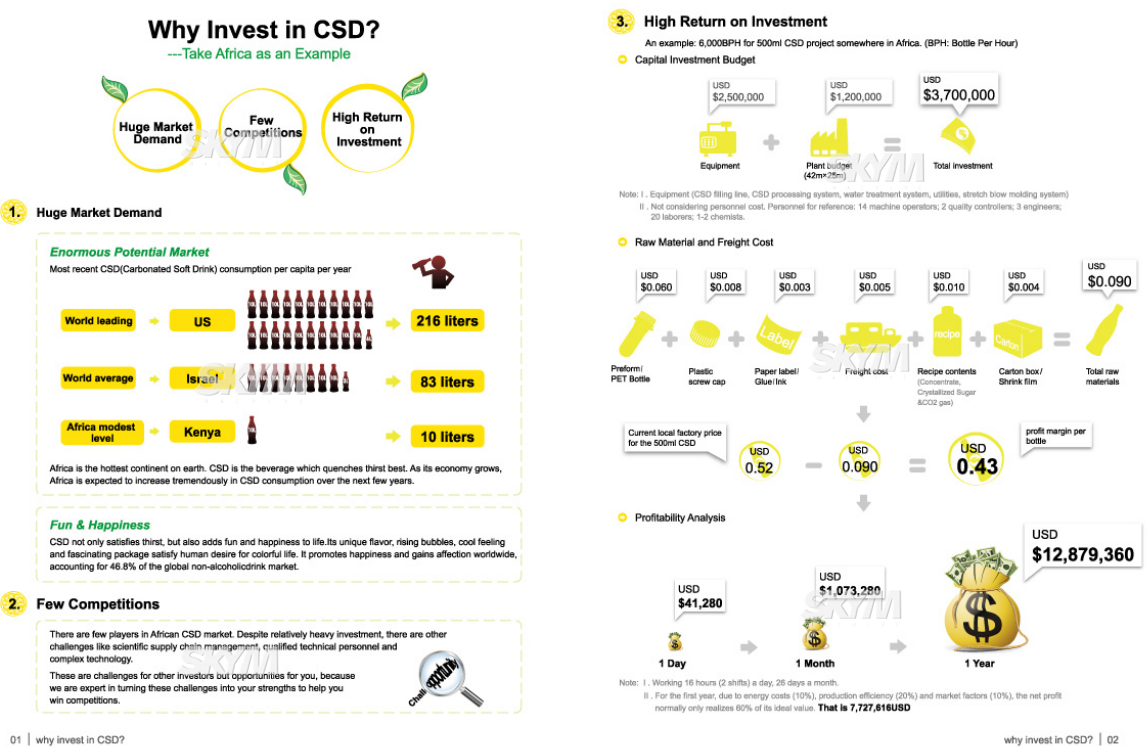

Why Invest In CSD?

Plastic Bottle Carbonated Soft Drinks Bottling Machine /Carbonated Soft Drink Filling Machine Line

DCGF-series rinsing, filling, Capping 3-in-1 monobloc machine introduced by foreign advanced gas-filling technique is a high performance fully automatic liquid packaging equipment. Machine for carbonated beverage packaging machine has the following characteristics: filling tank, filling valves and other components in direct contact with the material are high-quality stainless steel or non-toxic materials, in line with food hygiene requirements: use of resistant seals hot rubber to meet the high-temperature sterilization process of user requirements: PCL programmable controller used to realize from the bottle into the machine to the packaging of finished using the automatic control of frequency control, easy to transfer the user to adjust prepared to meet the different process on the capacity requirements; using isobaric filling principle and popular spring-loaded valves, ensuring the quality of the beverage, using an advanced magnetic clutch adjustment screw cap torque device to ensure the quality of the blocks.

Rinser

Filler

Capper

Beverage Drink Mixing Machine

Product Paramenters

|

Model

|

DCGF 14-12-5

|

DCGF 16-16-5

|

DCGF 24-24-8

|

DCGF32-32-10

|

DCGF40-40-12

|

DCGF50-50-15

|

DCGF60-60-15

|

||||||

|

Bottle specifications(mm)

|

200ml To 2000ml

|

|

|

|

|

|

|

||||||

|

Capacity (350ml/bottle/hour)

|

2000-3000

|

3000-4000

|

6000-8000

|

8000-10000

|

12000-15000

|

15000-18000

|

18000-25000

|

||||||

|

Power supply(kw)

|

2.42

|

3.12

|

3.92

|

3.92

|

5.87

|

7.87

|

11.37

|

||||||

|

Overall dimension(L*W*H)MM

|

2360×1770×2700

|

2760×2060×2700

|

2800×2230×2700

|

3550×2650×2700

|

4700×3320×2700

|

5900×4150×2700

|

6700×5160×2700

|

||||||

|

Weight (KG)

|

2800

|

3650

|

4800

|

6000

|

7500

|

9800

|

11500

|

||||||

Customized Bottle Design

Real Picture Of Customer Factory

Customer Plant Layout

Related Products

Water Treatment System

This water treatment system is made by the

raw water tank through the pretreatment to

reverse osmosis desalting device to get pure

water. Pretreatment is by silica sand filter,

activated carbon filter, sodium ion exchanger

and the precision filter composition. The

reverse osmosis device the core parts adopt

the world famous water pump and reverse

osmosis RO membrane.

raw water tank through the pretreatment to

reverse osmosis desalting device to get pure

water. Pretreatment is by silica sand filter,

activated carbon filter, sodium ion exchanger

and the precision filter composition. The

reverse osmosis device the core parts adopt

the world famous water pump and reverse

osmosis RO membrane.

Automatic PET Bottle Blow Molding machine

Automatic blowing machine adopts our most advanced blowing technologies. This machine is a fully automatic,high intelligent,stable

and reliable blowing machine,with simple structure,and low energy consumption. It is very popular and well used in food

,beverages,cosmetics,pharmaceutical industry.

and reliable blowing machine,with simple structure,and low energy consumption. It is very popular and well used in food

,beverages,cosmetics,pharmaceutical industry.

Automatic PVC shrink labeling machine

Application: PVC / PET / OPS label sleeve

* Stainless steel Main Machine Frame / Famous electrical components

* Stainless steel Main Machine Frame / Famous electrical components

Automatic PE film shrink wrapping machine

This machine is suitable for wrapping and packaging of such products as pop-top, mineral water, bottles beer, drinks etc without bottom-tray(or with bottom-tray). Working with PE shrink tunnel to pack the goods perfectly. The whole producing of shrink wrapping machine process adopt the Germany advanced technology. And the main parts of shrink wrapping machine are imported from international famous companies, capability stable and using long-time.

Automatic palletizing machine

This machine adopts international advanced automatic palletizing technology, can achieve high speed and high efficiency

palletizing effect, improve production capacity. Compared with robot palletizing machine, low palletizing machine is mainly

characterized by fast palletizing speed, simpler and more reliable mechanical joint structure, and low equipment cost. Make it

easy for operators to operate and monitor the machine; Man machine friendly touch screen operation interface, can comprehensively

monitor the running state of the machine, automatic fault display and treatment method prompt, so that maintenance personnel in

the shortest time to deal with the fault, operation and maintenance is simple and convenient.

palletizing effect, improve production capacity. Compared with robot palletizing machine, low palletizing machine is mainly

characterized by fast palletizing speed, simpler and more reliable mechanical joint structure, and low equipment cost. Make it

easy for operators to operate and monitor the machine; Man machine friendly touch screen operation interface, can comprehensively

monitor the running state of the machine, automatic fault display and treatment method prompt, so that maintenance personnel in

the shortest time to deal with the fault, operation and maintenance is simple and convenient.

ABOUT SKYM

Zhangjiagang Sky Machine Co.,Itd is located at Leyu Economic Development Zone of Zhangjiagang City.Our Company was founding

in 2008.We committed to do the World’s most competitive liquid drink packaging manufacture suppliers.Focus on providing customers with safe,energy,saving,efficient equipment.And high quality,fast and personalized service. We sincerely invite businesses aroundthe world to build a professional relationship with us based on trust,benefits and the promising possibility for future development.

in 2008.We committed to do the World’s most competitive liquid drink packaging manufacture suppliers.Focus on providing customers with safe,energy,saving,efficient equipment.And high quality,fast and personalized service. We sincerely invite businesses aroundthe world to build a professional relationship with us based on trust,benefits and the promising possibility for future development.

Hot Searches