- Product Details

- {{item.text}}

Quick Details

-

CaO Content (%):

-

0%

-

CrO Content (%):

-

0%

-

SiC Content (%):

-

0%

-

Place of Origin:

-

Henan, China

-

Model Number:

-

customization

-

Brand Name:

-

Hongtai

-

Product name:

-

High Alumina Refractory Brick

-

Application:

-

Industrial Furnaces

-

Color:

-

Yellow

-

Size:

-

230*114*65mm

-

Certificate:

-

ISO9001:2008

-

Bulk density(g/cm3):

-

2.0-2.5g/cm3

-

Type:

-

manufacturer

-

Sample:

-

Sample Provided

-

Fe2O3:

-

Max 2%

-

OEM:

-

Yes

Quick Details

-

SiO2 Content (%):

-

43%

-

Al2O3 Content (%):

-

48%

-

MgO Content (%):

-

0%

-

CaO Content (%):

-

0%

-

CrO Content (%):

-

0%

-

SiC Content (%):

-

0%

-

Place of Origin:

-

Henan, China

-

Model Number:

-

customization

-

Brand Name:

-

Hongtai

-

Product name:

-

High Alumina Refractory Brick

-

Application:

-

Industrial Furnaces

-

Color:

-

Yellow

-

Size:

-

230*114*65mm

-

Certificate:

-

ISO9001:2008

-

Bulk density(g/cm3):

-

2.0-2.5g/cm3

-

Type:

-

manufacturer

-

Sample:

-

Sample Provided

-

Fe2O3:

-

Max 2%

-

OEM:

-

Yes

Refractory Clay Brick For Ladle Lining High Alumina Bricks Tunnel Kiln

Refractory Clay Brick For Ladle Lining High Alumina Bricks Tunnel Kiln

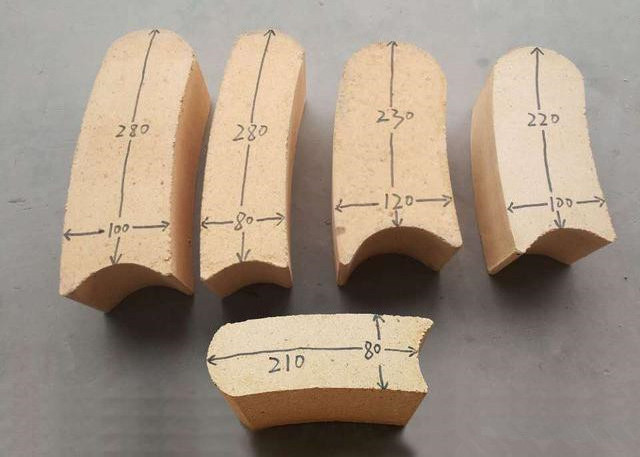

The arc of the universal arc brick is semi-circular, and the other end is a groove. No matter the thickness, it will be flexible. Because he has no shaft, the size is slightly deviated, and the same can be made into a circle. So called universal arc, this brick is used in ladle.

The main applications of Superior Quality fireclay universal arc refractory brick as Lining Material are the high temperature parts such as blast furnaces and coke stove, waste incinerators and glass melting furnaces.

Refractory Clay Brick For Ladle Lining High Alumina Bricks Tunnel Kiln features and advantages:

1. The dimensions are more accurate.

2. Low iron content and impurities

3. Good thermal stability;

4. High refractoriness,

5. anti alkaline /acid erosions,

6. Physical and chemical performances are good.

7. Strong thermal shock resistance.

Physical & Chemical index of Superior Quality fireclay universal arc refractory brick as Lining Material:

Common sizes:

|

Straight type |

Arch type |

Wedge type |

|

L×W×H (mm) 230×114×65 230×114×75 230×114×32 220×110×60 220×110×50 220×110×40 220×110×30 |

L×W×H/h (mm) 230×114×65/55 230×114×65/45 230×114×65/59 220×110×65/50 220×110×75/65 220×110×60/40 |

L×W×H/h (mm) 230×114×65/55 230×114×65/45 220×110×75/65 220×110×60/40 |

|

Other sizes according to customer requirements |

||

Refractory Clay Brick For Ladle Lining High Alumina Bricks Tunnel Kiln

Refractory Clay Brick For Ladle Lining High Alumina Bricks Tunnel Kiln are widely applied in coke oven, blast furnance, air stove, molten steel ladel, gating system, boiler, cement kiln, glass kiln, kinds of kiln lining and thermal equipment.

Refractory Clay Brick For Ladle Lining High Alumina Bricks Tunnel Kiln:

1.on wooden pallets with plastic cover: wooden pallet size :930*930 or 1000*1000mm,

2.Load weight of each pallet: 1.5-2.0 tons,

3.230*114*65mm:512PCS/Pallet, 230*114*75mm:448PCS/Pallet.

Shipping of Superior Quality fireclay universal arc refractory brick as Lining Material:

1.Our packaging is as per customer’s request

2.Normal goods delivered by sea transport

3.Sample shipping by express

4.We will shipping and delivery goods timely, quanlity and quantity guaranteed, and also in accordance with the contract and customer's requirment completely.

Payment Item :

1. Payment: T/T, Western Union,LC; Usually 30% deposits,70% balance before delivery or negotiations to solve.

2. MOQ: Usually 1Tons

3. Quality Warranty: 1 years

Delivery time :

1.Stocks:Within 5-7 days after receive the deposit.

2.Customization:Within 15-30 days after receive the deposite.