- Product Details

- {{item.text}}

Quick Details

-

Oiled or Non-oiled:

-

Slightly Oiled

-

Invoicing:

-

by actual weight

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

OEM

-

Outer Diameter:

-

4 - 60 mm

-

Thickness:

-

1MM

-

Grade:

-

Carbon Steel

-

Delivery Time:

-

40-60 days

-

Steel Grade:

-

St34-2/St37-2/St44-2/St52-3/E235/E355

-

Delivery condition:

-

BK BKW BKS GBK NBK

-

Material:

-

Carbon Steel

-

MOQ:

-

1 Ton

-

Surface:

-

BA/Black phosphated/Galvanizing

-

Shape:

-

Round

-

Packing:

-

Plastic Cap Cover

Quick Details

-

Section Shape:

-

Round

-

Surface Treatment:

-

BA/Black phosphated/Galvanizing

-

Tolerance:

-

±10%

-

Oiled or Non-oiled:

-

Slightly Oiled

-

Invoicing:

-

by actual weight

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

OEM

-

Outer Diameter:

-

4 - 60 mm

-

Thickness:

-

1MM

-

Grade:

-

Carbon Steel

-

Delivery Time:

-

40-60 days

-

Steel Grade:

-

St34-2/St37-2/St44-2/St52-3/E235/E355

-

Delivery condition:

-

BK BKW BKS GBK NBK

-

Material:

-

Carbon Steel

-

MOQ:

-

1 Ton

-

Surface:

-

BA/Black phosphated/Galvanizing

-

Shape:

-

Round

-

Packing:

-

Plastic Cap Cover

Detailed Images

Advantages

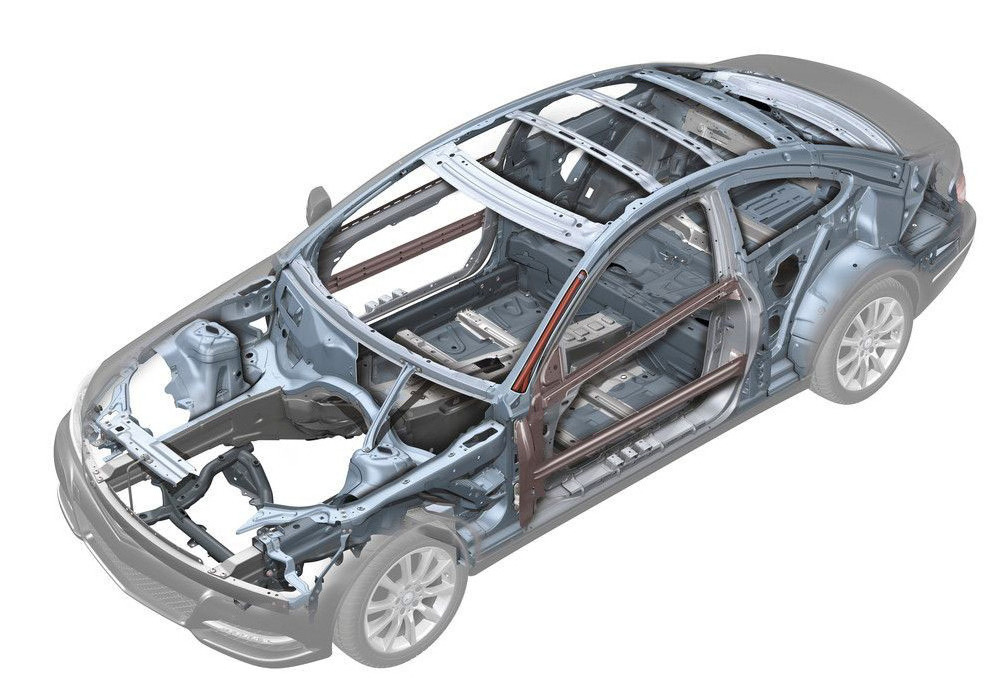

The car seat is one of the important devices in the car body, which is composed of a seat frame, a cushion, a backrest, a slide rail, and an adjustment mechanism.

Standard

|

Standard

|

Steel Grade

|

C

max |

Si

max |

Mn

max |

P

max |

S

max |

Al

|

|

DIN2394

|

St34-2

|

0.15

|

0.30

|

0.60

|

0.025

|

0.025

|

-

|

|

|

St37-2

|

0.17

|

0.30

|

0.70

|

0.025

|

0.025

|

-

|

|

|

St44-2

|

0.21

|

0.30

|

1.10

|

0.025

|

0.025

|

-

|

|

|

St52-3

|

0.22

|

0.55

|

1.60

|

0.025

|

0.025

|

≥0.020

|

|

Standard |

Steel Grade

|

C

max |

Si

max |

Mn

max |

P

max |

S

max |

Cr

|

Mo

|

|

EN10305-3

|

E235

|

0.17

|

0.35

|

1.20

|

0.025

|

0.025

|

-

|

-

|

|

EN10305-4

|

E355

|

0.17

|

0.55

|

1.60

|

0.025

|

0.025

|

-

|

-

|

|

Standard

|

DIN2394, EN 10305-3, and others

|

|

|

Production

|

Welding and forming

|

|

|

Material

|

Q235B, STKM 13C, ST52 and others

|

|

|

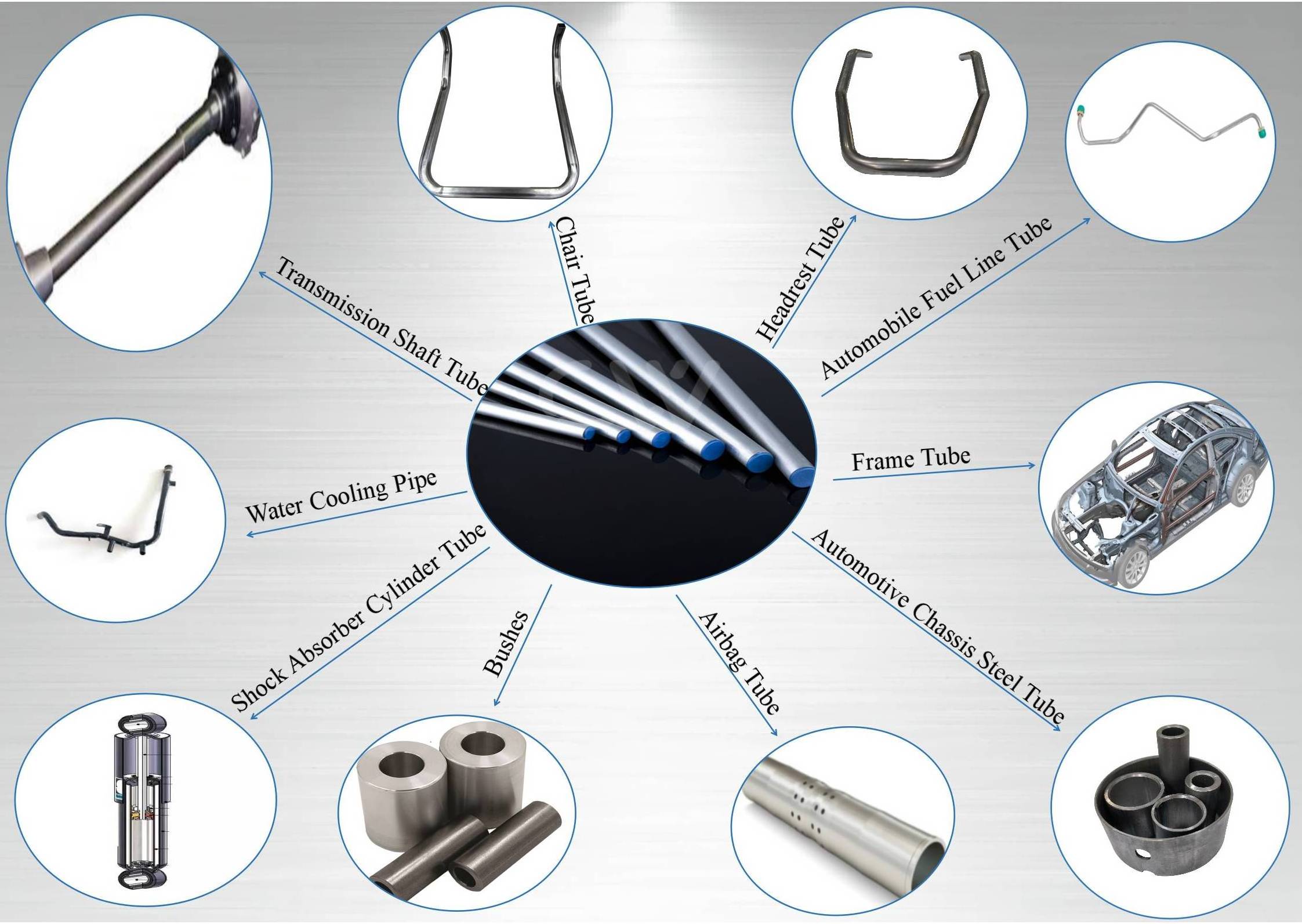

Application

|

Automotive seat

|

|

|

Surface Treatment

|

Cleaning,anodizing,electroplating,electrophoresis,painting

|

|

|

Detail size and shape as per customer drawing

|

|

|

Other standards and grade for reference

|

Standard

|

|

Steel Grades

|

Size Range

|

|

|

DIN

|

2393

|

St34-2/37-2/44-2/52-3

|

OD5 - 150mm × WT0.5-10-mm

|

|

|

|

2394

|

St 34-2/St 37-2/St 44-2/St 52-3

|

OD5 - 150mm × WT0.5-10-mm

|

|

|

EN

|

10305-2

|

E195/235/275/355

|

OD5 - 150mm × WT0.5-10-mm

|

|

|

|

10305-3

|

E195/235/275/355

|

OD5 - 150mm × WT0.5-10-mm

|

|

|

|

10305-5

|

E195/235/275/355

|

OD5 - 150mm × WT0.5-10-mm

|

|

|

|

10305-6

|

E195/235/275/355

|

OD5 - 150mm × WT0.5-10-mm

|

|

|

JIS

|

G3445

|

STKM11/12/13/etc

|

OD5 - 150mm × WT0.5-10-mm

|

|

|

ASTM

|

A512

|

1010/1020/1025/1030

|

OD5 - 150mm × WT0.5-10-mm

|

|

|

|

A513 TYPE 5

|

1010/1020/1025/1030

|

OD5 - 150mm × WT0.5-10-mm

|

|

|

GB/T

|

31315-2014

|

SPCC/Q195/Q235

|

OD5 - 150mm × WT0.5-10-mm

|

|

|

SAE

|

J525

|

1010/1020

|

OD5 - 150mm × WT0.5-10-mm

|

|

|

|

J526

|

1010/1020

|

OD5 - 150mm × WT0.5-10-mm

|

|

|

NF

|

A49-341

|

TS30a/TS34a/TS42a/TS37a

|

OD5 - 150mm × WT0.5-10-mm

|

|

|

BS

|

6323(-6)

|

CWS2/CWS4/CWS5

|

OD5 - 150mm × WT0.5-10-mm

|

|

Certificates:

According to EN 10204 3.1

Inspection Items: Tensile stength, Yield stength, Elongation, Flattenging, FlaringChemical analysisEddy Current

Test 100%, Size and surface checking 100%Other test item can be arranged as per request

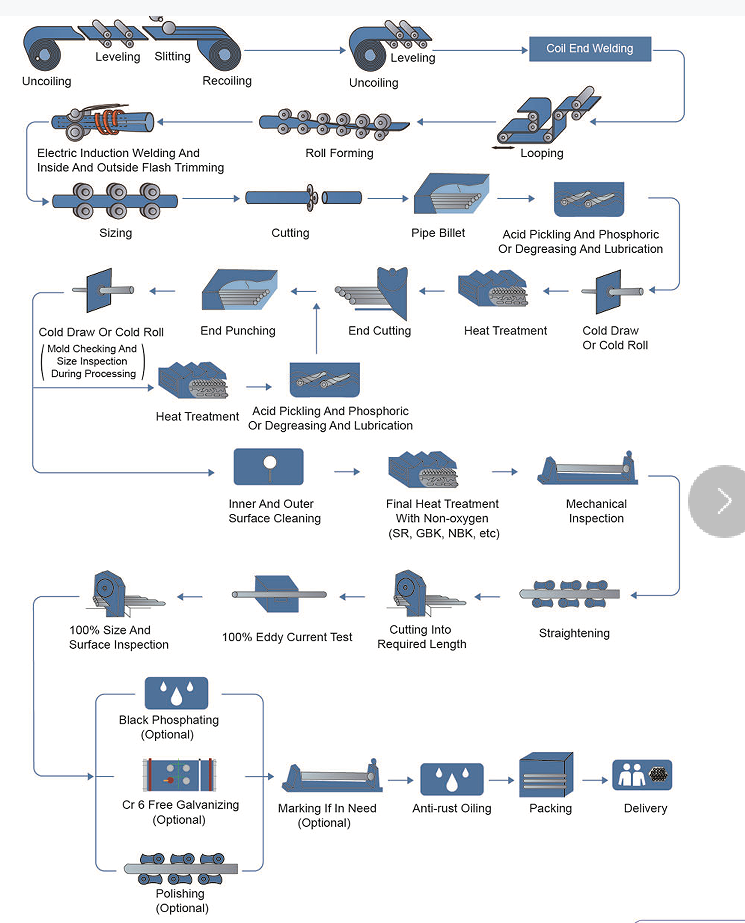

DELIVERY CONDITIONS:

The tubes can be produced in the following delivery conditions:

BK (+C) Cold finished/hard (cold finished as drawn).

No heat treatment after the last cold forming process.

BKW (+LC) Cold finished/soft (lightly cold worked)

After the last heat treatment there is a light finishing pass (cold drawing).

BKS (+SR) Cold finished/stress relieve annealed.

After the final cold forming process the tubes are stress relieve annealed.

GBK (+A) Annealed.

After the final cold forming process the tubes are annealed in a controlled atmosphere.

NBK (+N) Normalized. (Mainly focus on)

After the final cold forming process the tubes are annealed above the upper transformation point in a controlled atmosphere

Manufacture Process:

FAQ

1. who are we?

We are based in Jiangsu, China, start from 2010,sell to Eastern Asia(20.00%),Mid East(20.00%),Eastern Europe(15.00%),Southeast Asia(15.00%),Northern Europe(10.00%),Domestic Market(10.00%),South America(5.00%),Western Europe(5.00%),South Asia(0.00%),North America(0.00%),Oceania(0.00%),Southern Europe(0.00%),Central America(0.00%),Africa(0.00%). There are total about 11-50 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Steel Pipe, Seamless Pipe, Hydraulic Oil Tube, Precision Tube, Stainless Steel Tube

4. why should you buy from us not from other suppliers?

Production: Advanced production line and drawing with special oil to make the surface in best condition. Lower roughness and good mechanical performance. Inspection before delivery: Professional team for inspection and randomly check

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,DDP,DDU;

Accepted Payment Currency:USD,EUR,HKD,CNY;

Accepted Payment Type: T/T,L/C,MoneyGram;

Language Spoken:English,Chinese,Spanish,Japanese

Hot Searches