- Product Details

- {{item.text}}

Quick Details

-

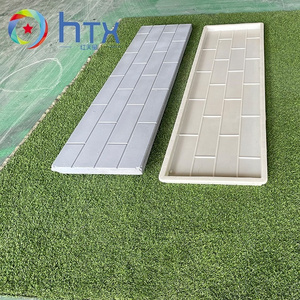

Model Number:

-

YC-OA001

-

Product Name::

-

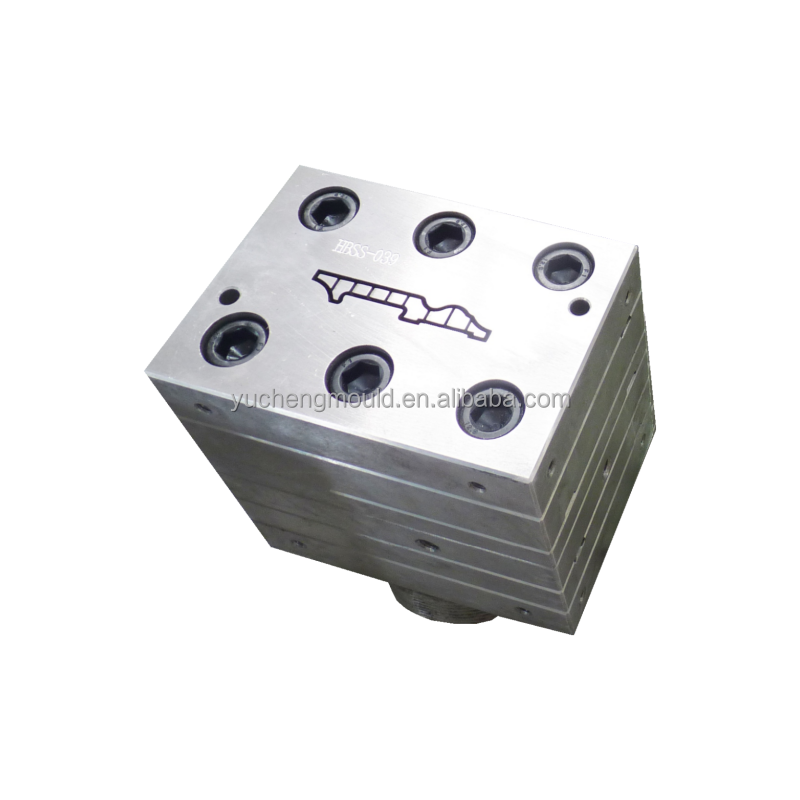

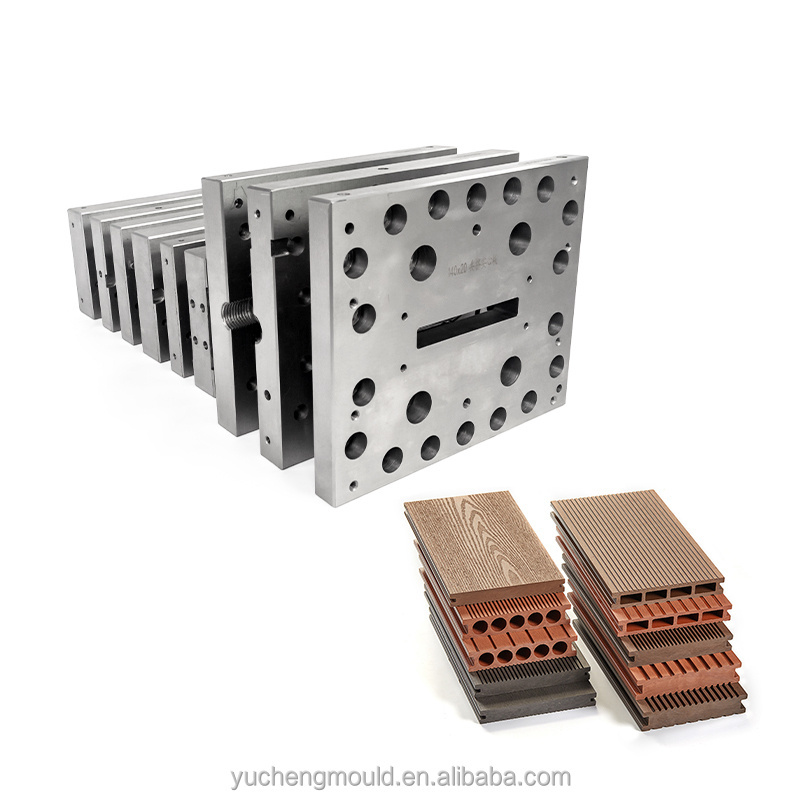

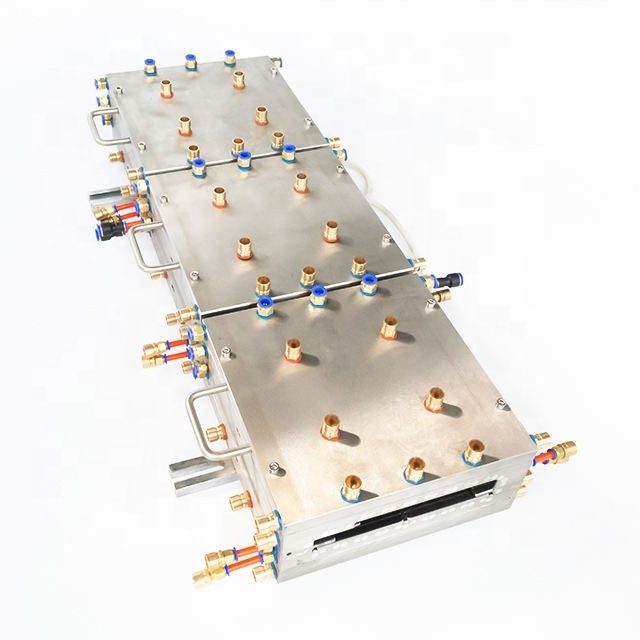

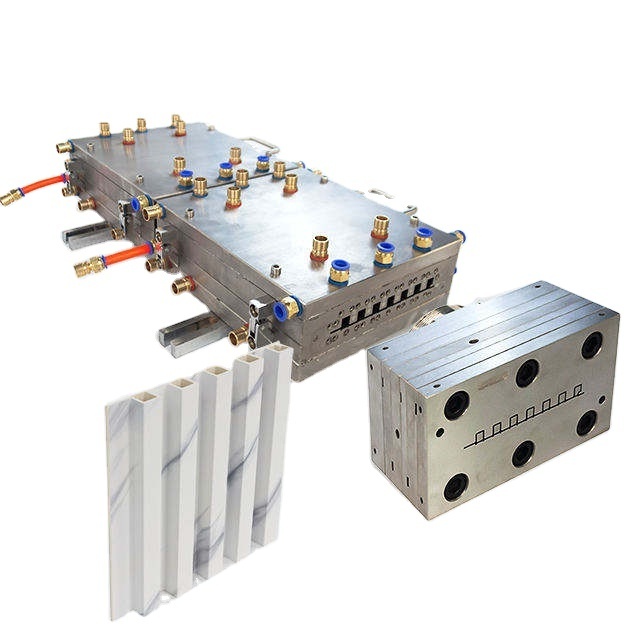

Wood plastic foaming mould

-

Color:

-

Silver Grey

-

Material:

-

Steel/P20/718/Nak80/S316/AISI H13/Resin/silicon Rubber

-

size:

-

Customized Size

-

Delivery Time:

-

30days

-

Product Name:

-

Plastic Injection Mold

-

Packing:

-

Wodden Case

-

Quality:

-

Premium OEM Original

-

Delivery:

-

Sea

Quick Details

-

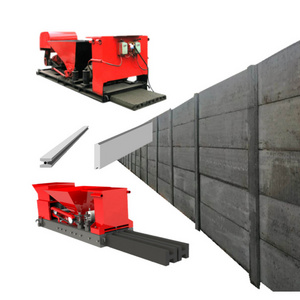

Shaping Mode:

-

Plastic Extrusion Mould

-

Place of Origin:

-

Hubei, China

-

Brand Name:

-

yucheng

-

Model Number:

-

YC-OA001

-

Product Name::

-

Wood plastic foaming mould

-

Color:

-

Silver Grey

-

Material:

-

Steel/P20/718/Nak80/S316/AISI H13/Resin/silicon Rubber

-

size:

-

Customized Size

-

Delivery Time:

-

30days

-

Product Name:

-

Plastic Injection Mold

-

Packing:

-

Wodden Case

-

Quality:

-

Premium OEM Original

-

Delivery:

-

Sea

Hot Searches