- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Chaosheng

-

Voltage:

-

8KW

-

Power:

-

customized

-

Dimension(L*W*H):

-

6000*1300*1500mm

-

Weight:

-

1200

-

Function:

-

Roller Automatically

-

Control System:

-

PLC+ Servo motor

-

bod color:

-

blue

-

gross weight::

-

1200kgs

-

power:

-

8KW

-

external size::

-

6000*1300*1500mm

-

Pipe Length:

-

1.2M~6M

-

Pipe diametal:

-

15mm~44mm

-

capacity:

-

720pcs /H

-

gurantee period:

-

1 year

Quick Details

-

Application:

-

paint Roller Winding

-

Production Capacity:

-

480~7000pcs/H

-

Marketing Type:

-

New Product 2023

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Chaosheng

-

Voltage:

-

8KW

-

Power:

-

customized

-

Dimension(L*W*H):

-

6000*1300*1500mm

-

Weight:

-

1200

-

Function:

-

Roller Automatically

-

Control System:

-

PLC+ Servo motor

-

bod color:

-

blue

-

gross weight::

-

1200kgs

-

power:

-

8KW

-

external size::

-

6000*1300*1500mm

-

Pipe Length:

-

1.2M~6M

-

Pipe diametal:

-

15mm~44mm

-

capacity:

-

720pcs /H

-

gurantee period:

-

1 year

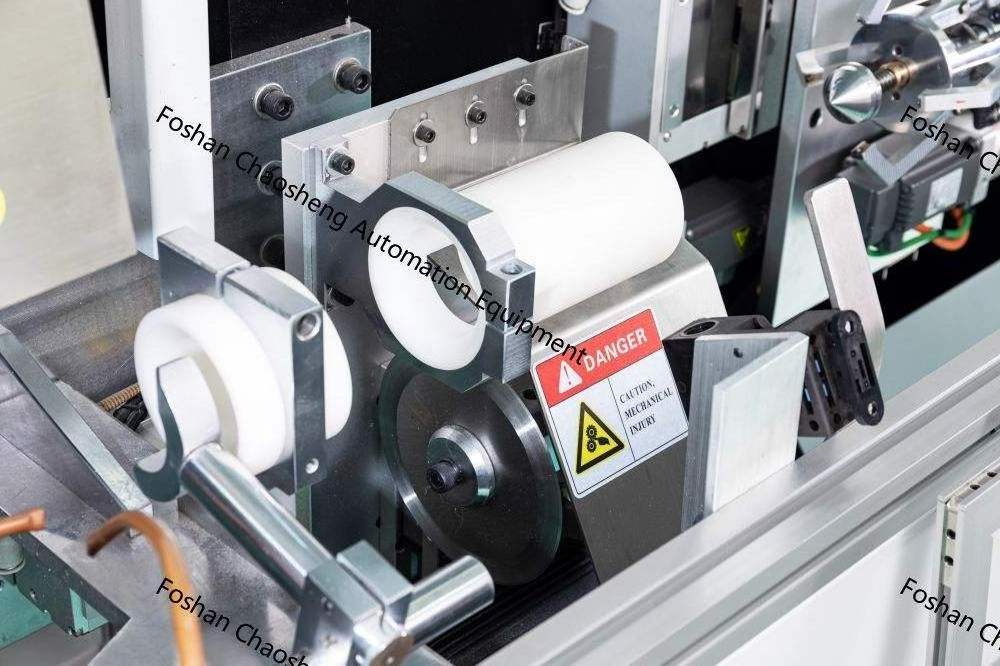

1>The automatic paint roller thermofusion machine automatically loading pipes, consistent continuous winding, and automatically.

2>The automatic paint roller thermofusion machine is equipped with thermobonding / thermofusion (suitable for PP pipe,flame supervision,temperature adjustment) technology.

3>Customized production according to different diameter of pipes and different length of production line

4>Approximate output is up to 8 meters of wound tubes per minute.It can produce more than 16,000 pieces of 9inch rollers per day(8 hours working time).

5>Fast changeover between different diameter.

Diameter: 11-57.5mm(others in requirement)

PP Pipe Length: from 1.28m to1.83m

Speed: 1800~2000pcs/H(6m in low speed and 8m in high speed, you could choose on the PLC program)

Core Material: PP pipe, above1.35mm

Operating Control Mode: PLC

|

O verall dimensions: L*W*H |

6000*1300*1500mm |

|

Total weight |

1200KGS |

|

Voltage |

AC110~380V 50Hz |

|

Total power |

2.8KW |

|

Air consumption |

0.5m3 |

|

Gas consumption: |

15kgs/tin for 16hours machine running |

|

1-Oxygen consumption: |

15mpa/tin, 4tins for 16hours machine running |