- Product Details

- {{item.text}}

Quick Details

-

dimension:

-

as to customer's drawing

-

Type:

-

grounding bus bar

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Material:

-

T2 copper

-

Copper Foil Thickn:

-

s: 0.1mm,0.15mm, 0.2mm and 0.5mm

-

dimension:

-

as to customer's drawing

-

Type:

-

grounding bus bar

high voltage busbar

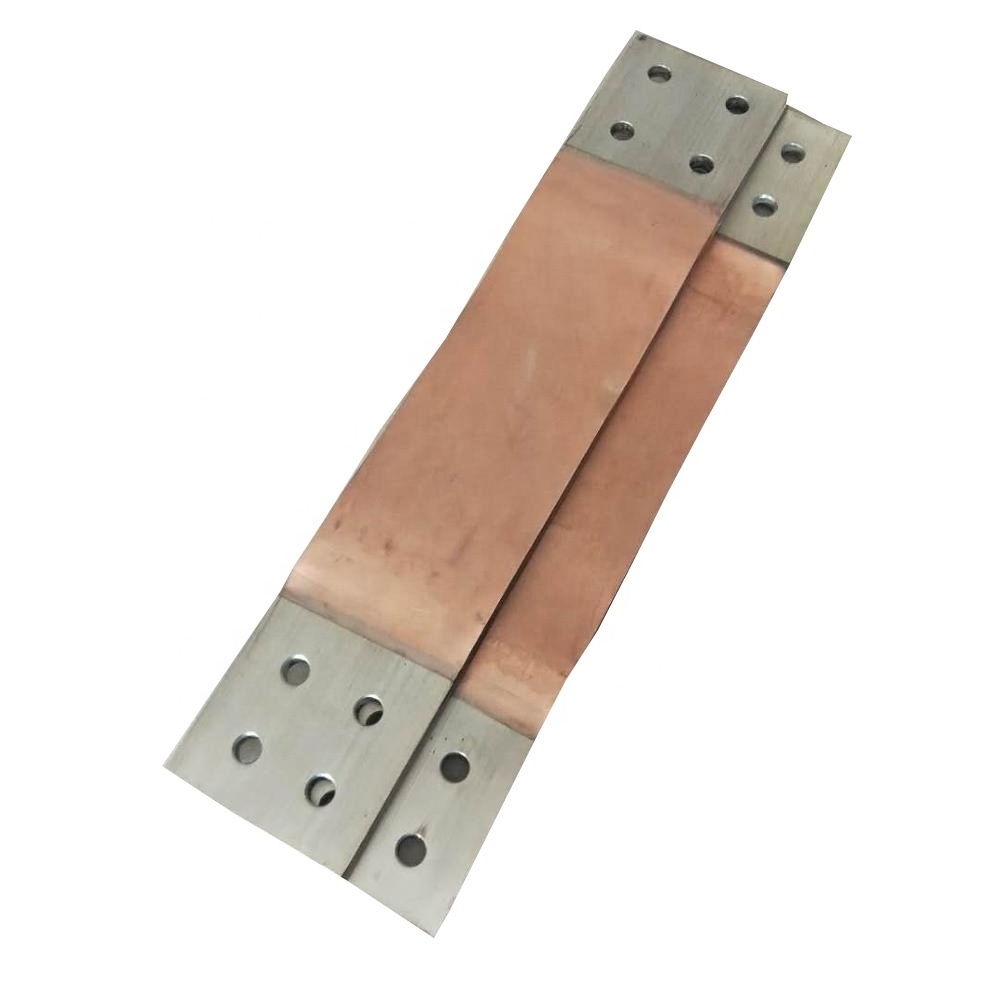

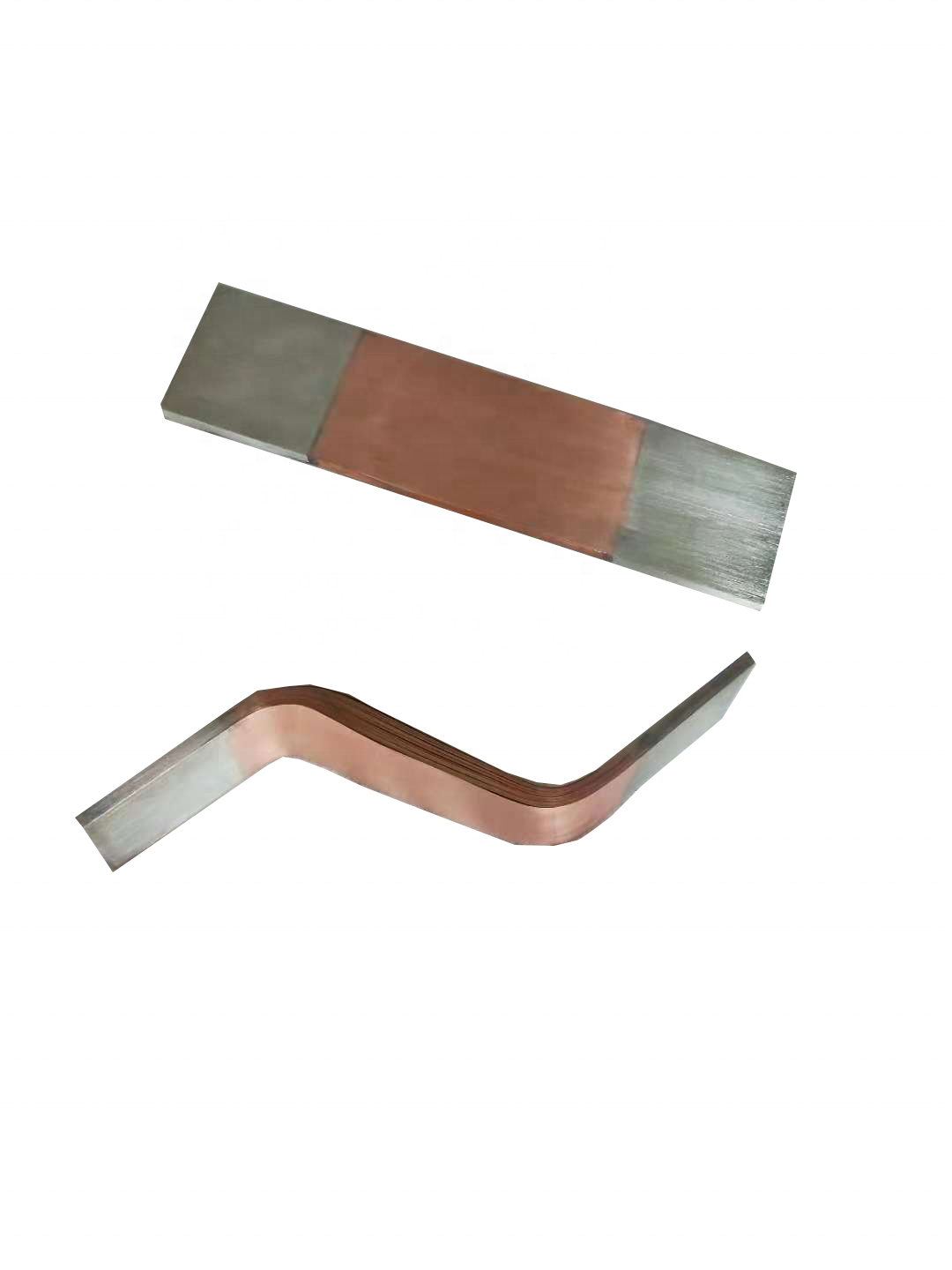

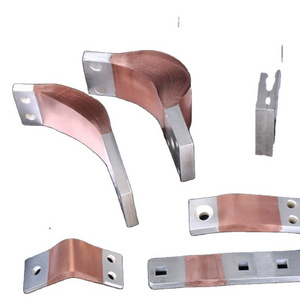

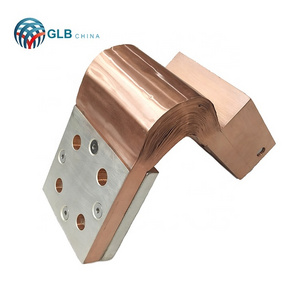

Pressure welding soft connect

or

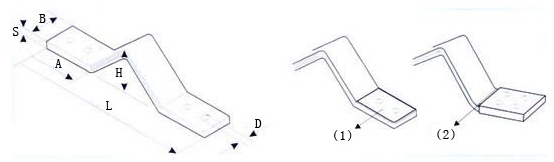

The pressure welding is to press the copper foil laminations together, using molecular diffusion welding, and forming by high-current heating and pressure welding.

Copper foil: 0.03mm to 0.3mm thick.

The contact surface can be tinned or silver plated according to user

s

’

requirements.

Description of pressure welding / brazing

In order to ensure the flatness of the contact surface,

When A is greater than 90mm and B is greater than 60mm; use the contact surface paste copper friend (1mm thick) pressure welding process, see the scheme (I) shown in the figure.

When A is greater than 140mm and B is greater than 130mm: Brazing process is used, see the scheme (II) shown in the figure.

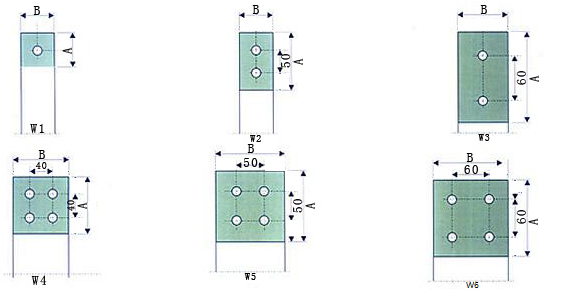

Technical parameters

See the table below.

The width, length and drilling holes not included in the table below can be processed according to user requirements.

The allowable current carrying capacity is a reference value. This value is related to the installation and use conditions of the soft connector.

Scheme (II)

Technical parameter table of pressure welding / brazing

|

ED copper |

Section mm 2

|

A mm |

B mm |

S mm |

L mm |

H mm |

Holes Diameter mm |

End drilling |

Current capacity A |

|

PWR 200/180/40 |

200 |

50 |

40 |

5 |

180 |

40 |

13 |

W1 |

600 |

|

PWR 200/230/40 |

200 |

50 |

40 |

5 |

230 |

40 |

13 |

W1 |

800 |

|

PWR 320/230/40 |

320 |

50 |

40 |

8 |

230 |

43 |

13 |

W1 |

800 |

|

PWR 400/230/40 |

400 |

50 |

40 |

10 |

230 |

45 |

13 |

W1 |

900 |

|

PWR 250/250/50 |

250 |

60 |

50 |

5 |

250 |

45 |

13 |

W1 |

700 |

|

PWR 400/250/50 |

400 |

60 |

50 |

8 |

250 |

48 |

13 |

W1 |

950 |

|

PWR 500/250/50 |

500 |

60 |

50 |

10 |

250 |

50 |

13 |

W1 |

1100 |

|

PWR 480/300/60 |

480 |

90 |

60 |

8 |

300 |

70 |

13 |

W2 |

1100 |

|

PWR 600/300/60 |

600 |

90 |

60 |

10 |

300 |

70 |

13 |

W2 |

1200 |

|

PWR 640/300/80 |

640 |

90 |

60 |

8 |

300 |

70 |

13 |

W4 |

1350 |

|

PWR 800/350/100 |

800 |

90 |

60 |

10 |

300 |

70 |

13 |

W4 |

1500 |

|

PWR 960/300/80 |

960 |

90 |

60 |

12 |

300 |

70 |

13 |

W4 |

1700 |

|

PWR 800/350/50 |

800 |

110 |

100 |

8 |

300 |

80 |

13 |

W5 |

1550 |

|

PWR 1000/350/100 |

1000 |

110 |

100 |

10 |

350 |

80 |

13 |

W5 |

1800 |

|

PWR 1200/350/100 |

1200 |

110 |

100 |

12 |

350 |

80 |

13 |

W5 |

1900 |

|

PWR 1200/400/120 |

1200 |

130 |

120 |

10 |

400 |

80 |

13 |

W6 |

2000 |

|

PWR 1440/400/120 |

1440 |

130 |

120 |

12 |

400 |

80 |

13 |

W6 |

2200 |

|

PWR 1500/450/150 |

1500 |

160 |

150 |

10 |

450 |

80 |

18 |

W6 |

2300 |

|

PWR 1600/450/160 |

1600 |

170 |

160 |

10 |

450 |

80 |

18 |

W6 |

2500 |

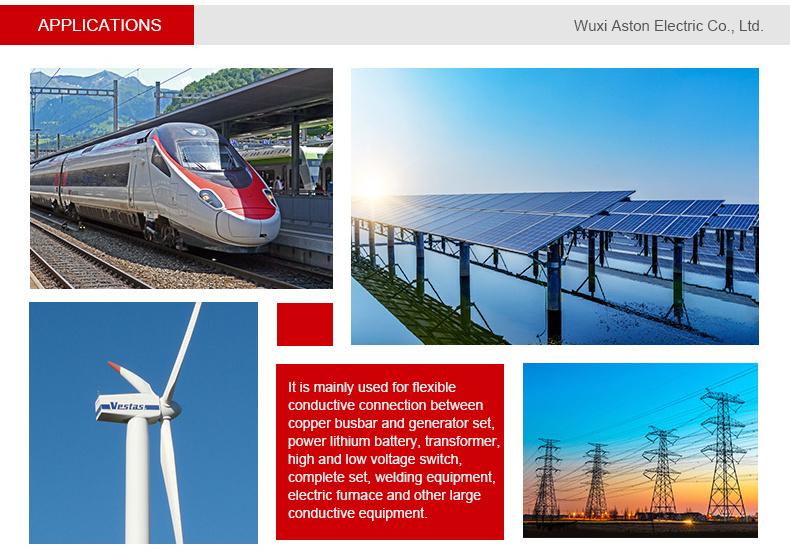

Main products range of :

different types of Flexible copper busbar connectors,

Copper braid jumper,

Solid copper busbar,

Aluminum foil laminated busbar connector