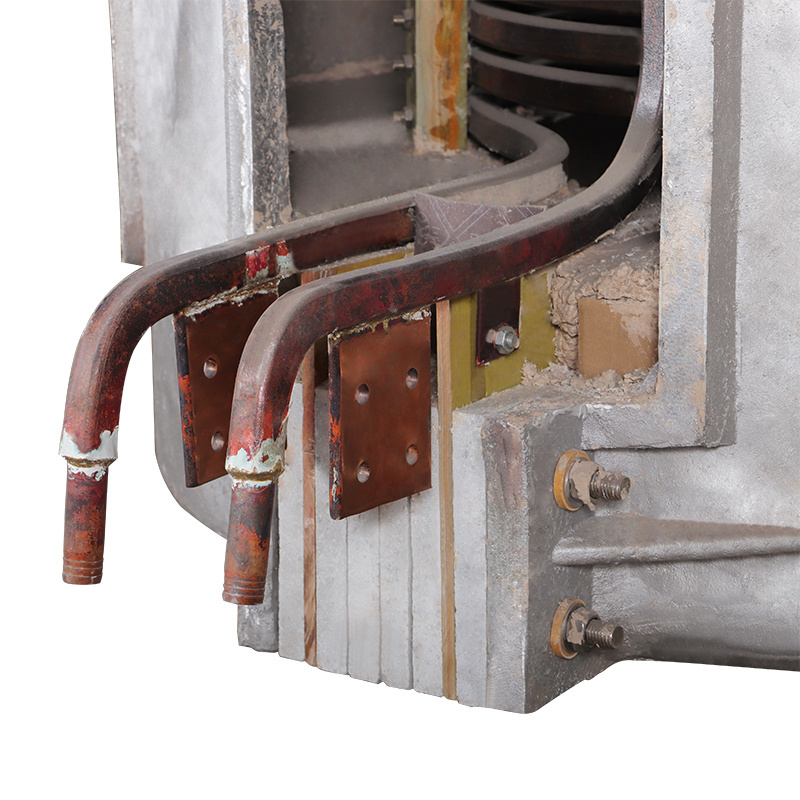

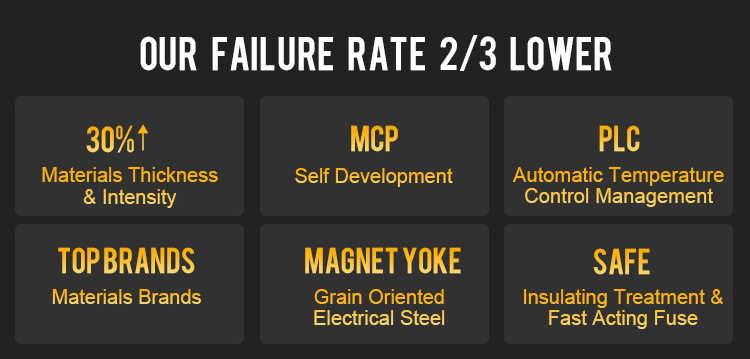

1.There is a large leakage of magnetic flux during the operation of the aluminum-clad induction furnace. The case (aluminum) will be oxidized strongly under high temperature conditions, which will result in the decrease of metal toughness.If the aluminum shell is not thick enough, it will deform and be damaged.

3.The copper tube of the sensor should be of good quality.This will save electricity.Long service life. If not good use of copper pipe.It can cause the device to consume a lot of power.There is a breakdown and maintenance is inconvenient.

2.Good insulation treatment gives workers safe work and production, and the furnace will not leak electricity even if it works for many years.If power leakage is found and needs to be stopped for maintenance, it will be very troublesome and will also bring economic losses to the factory.