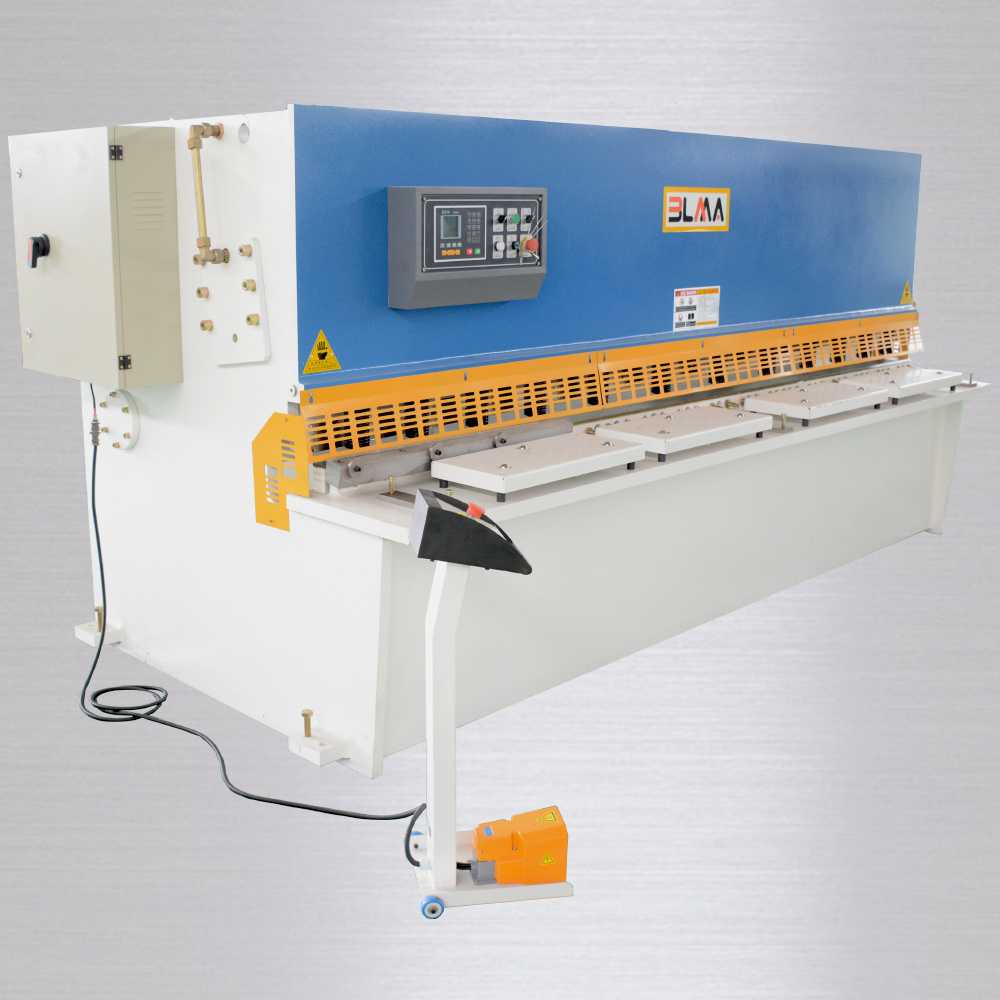

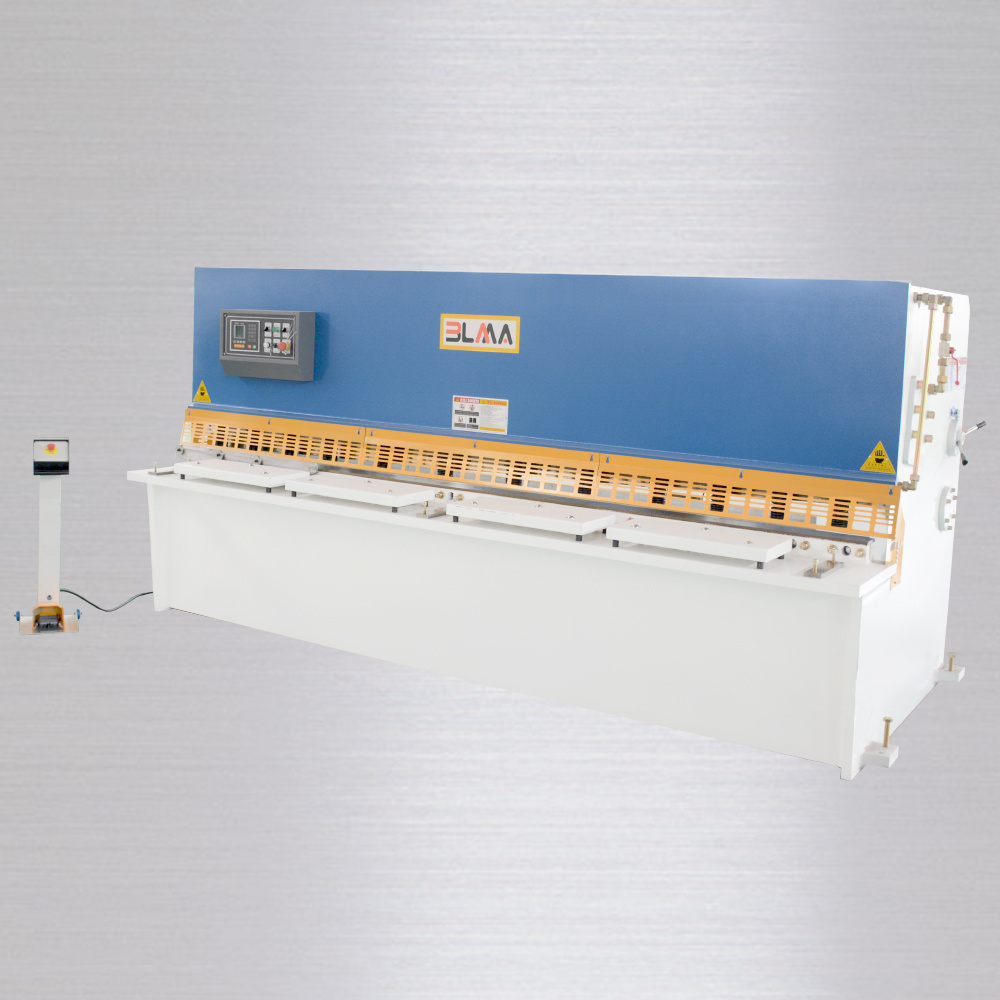

- Product Details

- {{item.text}}

Quick Details

-

Blade Length (mm):

-

2600 mm

-

Backgauge Travel (mm):

-

20 - 600 mm

-

Throat Depth (mm):

-

100 mm

-

Brand Name:

-

BLMA

-

Power (kW):

-

7.5 kW

-

Weight (KG):

-

6200 KG

-

Place of Origin:

-

ANHUI,CHINA

-

Voltage:

-

380V/220V/440V/600V

-

Dimension(L*W*H):

-

3900x1650x1800

-

Year:

-

2023

-

Hydraulic system:

-

Rexroth Germany

-

Electric parts:

-

Schneider France

-

Blade material:

-

9CrSi/6CrW2Si

-

Type:

-

Swing Beam Shear

Quick Details

-

Max. Cutting Width (mm):

-

3200

-

Max. Cutting Thickness (mm):

-

6 mm

-

Shearing Angle:

-

1.5

-

Blade Length (mm):

-

2600 mm

-

Backgauge Travel (mm):

-

20 - 600 mm

-

Throat Depth (mm):

-

100 mm

-

Brand Name:

-

BLMA

-

Power (kW):

-

7.5 kW

-

Weight (KG):

-

6200 KG

-

Place of Origin:

-

ANHUI,CHINA

-

Voltage:

-

380V/220V/440V/600V

-

Dimension(L*W*H):

-

3900x1650x1800

-

Year:

-

2023

-

Hydraulic system:

-

Rexroth Germany

-

Electric parts:

-

Schneider France

-

Blade material:

-

9CrSi/6CrW2Si

-

Type:

-

Swing Beam Shear

Main Features

* Multi-step programming function, the back gauge can be automatically operated and continuously positioned, realizing the automatic adjustment of the back gauge position

* The cut count function displays the number of cuts in real time

* The use of high-precision machining ball screws and linear guides ensures positioning accuracy

Product Paramenters

Machine details

Systems

E21S Control System

Backgauge control.

Control for general AC motor

Intelligent positioning

Double programmable digital output, stock counter

Program memory of up to 40 programs

Up to 25 steps per programs

One side positioning, Retract function

One key backup/restore of parameters

Control for general AC motor

Intelligent positioning

Double programmable digital output, stock counter

Program memory of up to 40 programs

Up to 25 steps per programs

One side positioning, Retract function

One key backup/restore of parameters

ES10 CNC Control System

7-inch TFT real color touch screen

Menu programming interface

Programmable cutting function

Automatic calculation of cutting length

Automatic correction of backgauge

Backgauge is controlled by servo motor

Automatically calculate blade clearance

Automatically calculate cutting angle

Support multi languages.

Menu programming interface

Programmable cutting function

Automatic calculation of cutting length

Automatic correction of backgauge

Backgauge is controlled by servo motor

Automatically calculate blade clearance

Automatically calculate cutting angle

Support multi languages.

DAC310 (DELEM) CNC Control System

Bright LCD 128 x 64 display

Backgauge control

Gap control

Stroke length limitation

Actual and Programmed position visualization

Stock counter

Programmable up to 100 steps

Panel-based housing

Servo control / inverter / 2-speed AC control

Backgauge control

Gap control

Stroke length limitation

Actual and Programmed position visualization

Stock counter

Programmable up to 100 steps

Panel-based housing

Servo control / inverter / 2-speed AC control

Parts

Pressing Mechanism

shearing machine is equipped with plate pressing mechanism. The pressing head presses down to compress the plate when cutting plate.

Steel Ball Transmission Structure

BLMA shearing machine is equipped with steel ball transmission structure, which can saves the operator's effort in feeding material and increase the efficiency.

Guardrail

BLMA shearing machine adopts guardrail to prevent the operator from accidentally operating and pinching, and also avoiding work injuries during cutting errors.

Laser Light Alignment (optional)

The laser light alignment device will help you positioning the cutting line quickly. This is convenient and time-saving.

FAQ

Q1:Are you trading company or manufacturer ?

A1: We are manufacturer of pipe tube processing.

A1: We are manufacturer of pipe tube processing.

Q2: How long is your delivery time?

A2: The standard model is 15-30 days, the customized model is 30-60 days.

Q3: How to choose the model of machines?

A3: The thickness, width and material.

Q4: What is your term of payment ?

A4:30% T/T in advance, the balance before shipment.

A2: The standard model is 15-30 days, the customized model is 30-60 days.

Q3: How to choose the model of machines?

A3: The thickness, width and material.

Q4: What is your term of payment ?

A4:30% T/T in advance, the balance before shipment.

Our services

Pre-service

1.We will help you confirm the model of our machine according to your offered pipe information.

2.You are very welcome to see our machine how to work in the factory before you place an order

with us.

with us.

Aftersales-service:

1.

Our machine is easy to use. Operation manual and teaching video will be sent out with machine.

We also offer free training in our factory, the following is our training contents:

Detailed function of our machine, 1 hour;

NC control using, 0.5 hour;

Tooling installation and adjustment, 0.5-1 hours;

Maintenance and repair, 0.5-1 hours;

Real operation according client products, 1-2 hours.

During the training period,we offer free pick-up,hotel and food.

2. We guarantee machine quality for 13 months, during this period, if spare parts of the machine are not man-made damage, we can send the component to the customer by DHL, TNT freely.

3.Our factory provide the service for the customer forever, if the customer need operation help,we

provide 24 hours on-line reply service.

provide 24 hours on-line reply service.

Hot Searches