- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

AC220V/110V, 50Hz/60Hz

-

Power:

-

40-370

-

Dimension(L*W*H):

-

72*140*275 100L

-

Weight:

-

100

-

Reactor base material:

-

High-quality stainless steel and GG3.3 glass

-

Reaction vessel reactors Function:

-

Reflux,distallation,biogas production,mixing,etc

-

Stir flange:

-

Steel core coated by PTFE

-

Temperature testing:

-

Yes, PT100 sensor probe offered

-

Anti Alkaline:

-

Yes

-

Anti H2SO4/HNO3:

-

Yes

-

Reaction vessel glass size:

-

1-200L

-

Certification:

-

CE,ISO9001

Quick Details

-

Capacity:

-

1L~200L

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

SHBC

-

Voltage:

-

AC220V/110V, 50Hz/60Hz

-

Power:

-

40-370

-

Dimension(L*W*H):

-

72*140*275 100L

-

Weight:

-

100

-

Reactor base material:

-

High-quality stainless steel and GG3.3 glass

-

Reaction vessel reactors Function:

-

Reflux,distallation,biogas production,mixing,etc

-

Stir flange:

-

Steel core coated by PTFE

-

Temperature testing:

-

Yes, PT100 sensor probe offered

-

Anti Alkaline:

-

Yes

-

Anti H2SO4/HNO3:

-

Yes

-

Reaction vessel glass size:

-

1-200L

-

Certification:

-

CE,ISO9001

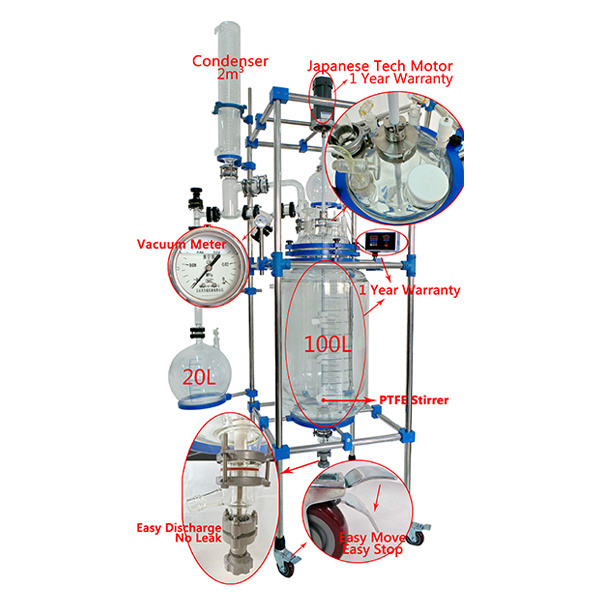

Jacketed reactor, Chemical Reactor, Pressure vessel microbiology laboratory equipm fractional distillation

Reaction vessel fractional distillation commonly used in biochemical,modern fine chemical,pharmaceutical,scientific experiments and other industries.

Reaction vessel can do concentration , distillation , reflow , separation , purification reaction in the condition of constant speed,constant force,constant temperature.

SHBC can design under your instructions. Accept OEM.

fractional distillation

| FEATURES |

- Borosilicate glass 3.3

- Compact stainless steel mobile frame,

- PTFE seal,diameter 20mm PTFE stirrer(stainless steel core, PTFE coated)

- PTFE active discharge valve, electronic temperature measurement

- Constant speed stir controller

- Anti acid, anti alkali

- Explosion-proof device is optional

- With reflow and distillation system

- Temperature range: -80 to 300 degree

- Size: 1L, 2L, 3L,5L,10L,20L,30L,50L,100L,150L,200L

- Easy connect with HUBBER heating/cooling device by special valve

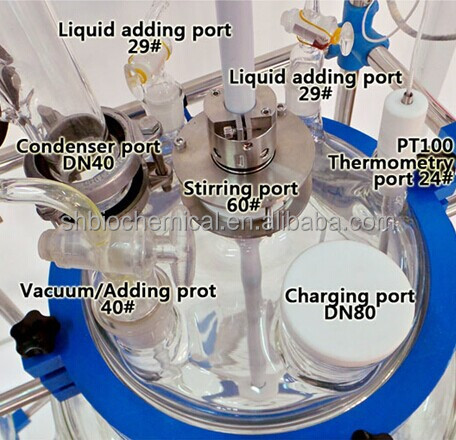

Jacketed reactor chemical reactor STANDARD DETAILS:

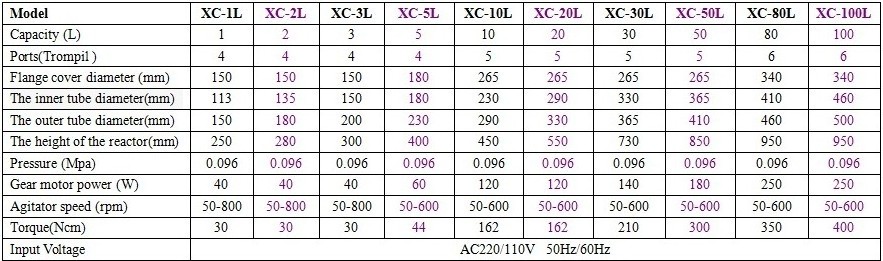

| TECHNICAL PARAMETERS for Double Jacket Glass Reactor |

Jacket heating reactor Reactor biodiesel, fractional distillation chemical reactor

Diamension of standard chemical reactor double glass reactor:

high pressure laboratory reactor, pressure vessel

high pressure laboratory reactor

| Payment & Shippment: |

| About us |

Our Advantages:

1. Our chemical reactor have good price with nice shape .

2. Stable avilibility, adequate stock, complete specification.

3. MOQ 1 unit.

4. The strong support of advanced tachnology and detection capability.

5. ISO certification.

6. Your reliable factory, 20years experience.

7. Professional service and technology support.

8. Delivery about 7 days upon receipt.

Main Markets:

North America

Europe

Australia/New Zealand

Middle East

Central/South America

Asia

Q:Are you a factory or a trading compay ?

A:We are manufacture.

Q:The reactor could be used for sterification,in an acidic invironment?

A: Yes .

Q:Wheather the impeller is durable for strong acids sch as H2SO4 or HNO3?

A: Yes.

Q:Is the standard model suitle for working under vacuum?

A: Yes.

Q: Is there a possibility of connecting an external system via an 'extra' output to the cove lid?

A : Yes.

Q:Is it possible to use oil instead of water in the jacket? What is the max.temperature possible?

A : Yes . Water heating equipment temperature range RT to 100 celsius degree, oil heating equipment range RT to 300 celsius degee.

Q:Is it possible to connect a reflux column instead of the condenser?

A : No . Condenser is necessary, otherwise the gas can't became liquid. Our stanard fitting have condenser and liquid/vapor devider, it could finish the function of distillation and reflux.

Q: Accept customize or OEM?

A : Yes .

Q:Warranty ?

A : 1 year international warranty.

Q:The MOQ ?

A : 1 Unit.

Q:Delivelye time:

S: About 7days upon receipt.

Q :Shipping method:

A :By air, by sea, FedEx,DHL ,etc

| How to Place an Order |

Step1 : Getting inquiry

Step2 : Quoting based on details provided

Step3 : Confirmation of prices and design layout

Step4 : Schematic diagram confirmation

Step5 : Shipping notice

Step6 : Getting the freight and balance

Step7 : Shipment

Step8 : After-sale service

Click " inquire" to contact with us!