- Product Details

- {{item.text}}

Quick Details

-

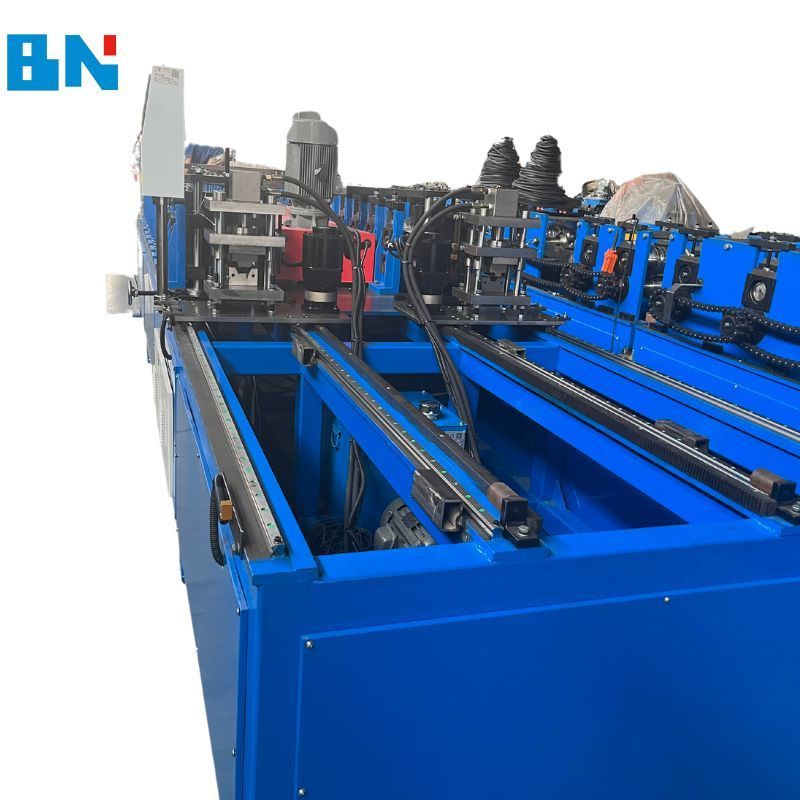

Brand Name:

-

BN

-

Voltage:

-

380V/50HZ 3Phase(as Customer's Request)

-

Power:

-

4kw

-

Dimension(L*W*H):

-

5500*800*1200

-

Weight:

-

3000 kg

-

Color:

-

as your requirement

-

Material thickness:

-

0.4-3mm

-

After-sales Service Provided:

-

Free spare parts

-

Certification:

-

ISO CE

-

Roll station:

-

14 stations(depend on the profile)

-

Main power:

-

5.5KW

-

Hydraulic power:

-

3kw

-

Control system:

-

PLC

-

Drive:

-

by chain

-

Shear material:

-

cr12

Quick Details

-

Work Pressure:

-

12Mpa

-

Production Capacity:

-

10-20m/min adjustable

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

BN

-

Voltage:

-

380V/50HZ 3Phase(as Customer's Request)

-

Power:

-

4kw

-

Dimension(L*W*H):

-

5500*800*1200

-

Weight:

-

3000 kg

-

Color:

-

as your requirement

-

Material thickness:

-

0.4-3mm

-

After-sales Service Provided:

-

Free spare parts

-

Certification:

-

ISO CE

-

Roll station:

-

14 stations(depend on the profile)

-

Main power:

-

5.5KW

-

Hydraulic power:

-

3kw

-

Control system:

-

PLC

-

Drive:

-

by chain

-

Shear material:

-

cr12

Product Description

Main Features

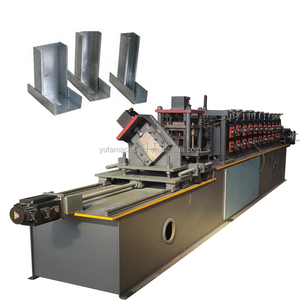

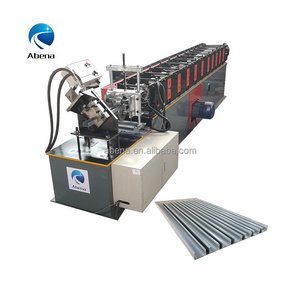

1. Keel size as per your drawing

2. Compact and elegant

3. PLC automatic control

4. Touch screen operation

profile

Equipment Flowsheet

De-coiler→feeding→roll forming→rectify→post cutting →output table

Detailed Technology

|

3T manual decoiler

|

|

|

|

Width of feeding

|

300mm

|

|

|

Dimensions

|

1700mm*1000mm*800mm

|

|

|

Bound of expand &fight

|

420mm-510mm

|

|

|

Capability

|

3000 Kg

|

|

|

Way of feeding

|

manual

|

|

|

Color

|

blue

|

|

|

|

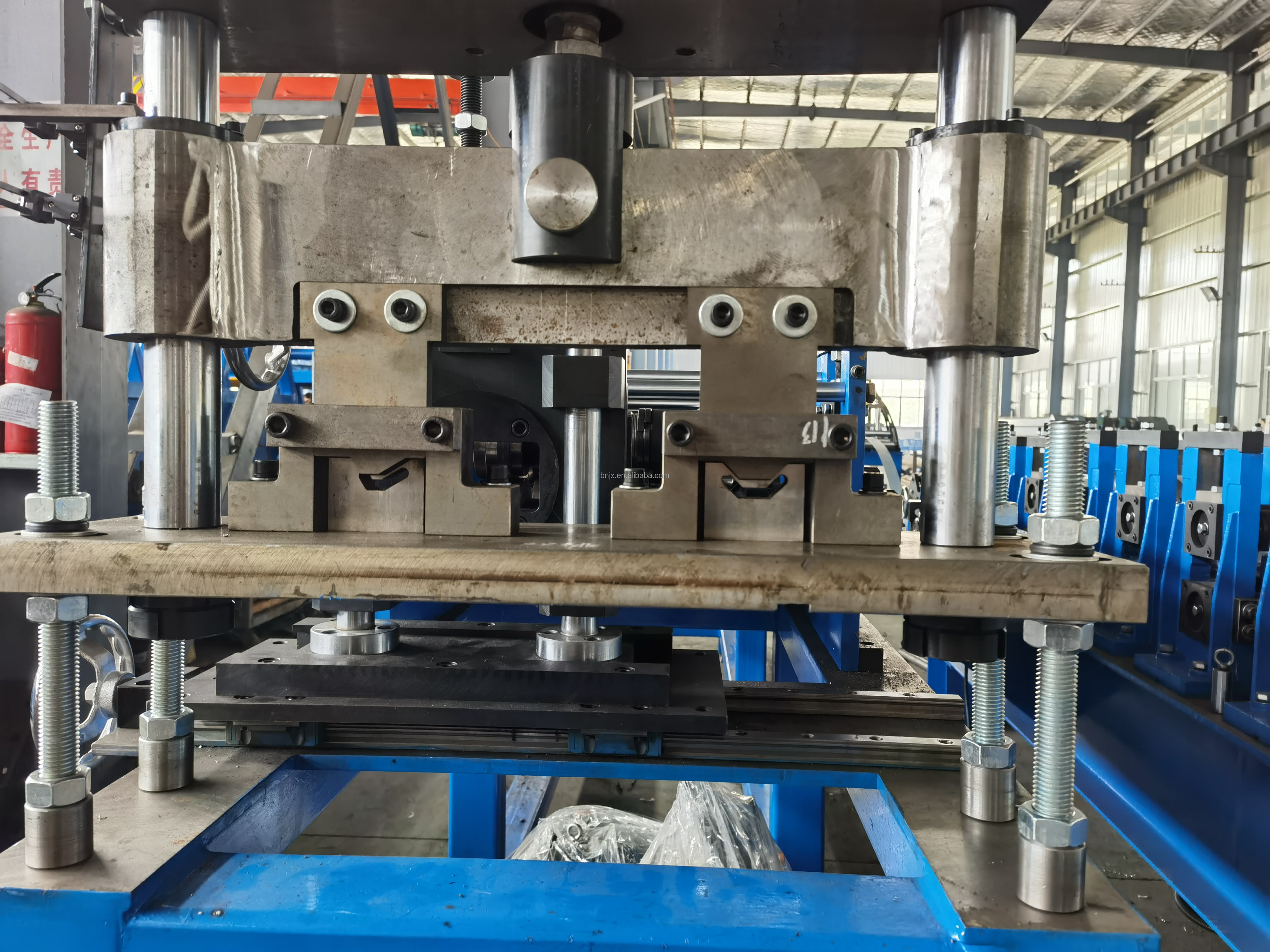

Forming Section

|

|

Thickness range

|

0.4-0.7mm GI sheet

|

|

Main motor power

|

7.5kw, AC motor, side motor to save space

|

|

Roll station

|

about 8stations +1 station of rectify

|

|

Shaft diameter

|

¢56mm

|

|

Roller material

|

chrome plated surface

|

|

Machine roll forming speed

|

0-15m/min

|

|

Transmission

|

by chain, one inch

|

|

manual out table

|

|

|

|

Frame

|

welding by square tube

|

|

|

Size

|

1.5m long*1m wide*1m high

|

|

|

Two out tables with support rolle

|

|

|

|

Quantity

|

2units

|

|

|

|

Hydraulic station

|

|

Hydraulic power

|

3kw

|

|

Working pressure

|

12Mpa adjustable

|

|

Solenoid valve

|

1 groups

|

|

Hydraulic oil

|

46# hydraulic oil

|

|

Color

|

Blue (or base on customer request)

|

|

Quantity

|

1

|

|

Control desk

|

|

|

|

Programmable setting of profile length and quantity

|

|

|

|

Automatic stopping of the equipment after completion of the cutting programme will be provided.

|

|

|

|

language

|

English and Chinese

|

|

|

Voltage, Frequency, Phase

|

380 V, 50 Hz, 3Phase

|

|

|

Control panel

|

Button-type switch and touch screen

|

|

|

Unit of length

|

millimeter

|

|

|

PLC brand

|

Panasonic

|

|

FAQ

Q1.Does one machine can only produce one size?

Not exactly. It depends on the type and version of machine you need.

Q2.Do you have after sales support?

Yes,we are happy to give advice and also have skilled technicians available to maintain the machine if needed.

3. You are trade company or factory?

We are Manufacturer,and a lso a CE manufacturer.

4.How long the machine could be made?

Normally speaking, high precision roll forming machine could be made out with 40 working days.If you need machines in hurry, we

can make it for you less than a month.

5. Do you provide customized?

Sure, we can design the equipment according to the data of the structural section you provide.Our engineers can offer the best

professional solution to our worldwide clients.Meanwhile we can provide door-to-door service.

6.How to visit your factory?

By high speed train from Shanghai to Wuxi, half an hour. You can also fly directly to Wuxi.

7.What's the warranty period?

12 months warranty period, starting from the date of the successful installation and commissioning of the equipments at the

Buyer’s Installation site.

8.May we visit your factory?

Sure,Warmly welcome to our factory at any time.

Not exactly. It depends on the type and version of machine you need.

Q2.Do you have after sales support?

Yes,we are happy to give advice and also have skilled technicians available to maintain the machine if needed.

3. You are trade company or factory?

We are Manufacturer,and a lso a CE manufacturer.

4.How long the machine could be made?

Normally speaking, high precision roll forming machine could be made out with 40 working days.If you need machines in hurry, we

can make it for you less than a month.

5. Do you provide customized?

Sure, we can design the equipment according to the data of the structural section you provide.Our engineers can offer the best

professional solution to our worldwide clients.Meanwhile we can provide door-to-door service.

6.How to visit your factory?

By high speed train from Shanghai to Wuxi, half an hour. You can also fly directly to Wuxi.

7.What's the warranty period?

12 months warranty period, starting from the date of the successful installation and commissioning of the equipments at the

Buyer’s Installation site.

8.May we visit your factory?

Sure,Warmly welcome to our factory at any time.

9. How to get a quotation?

1. Give me the dimension drawing and thickness, it is very important.

2. If you have requirements for production speed, power, voltage and brand, please explain in advance.

3. If you don't have your own outline drawing, we can

recommend some models according to your local market standard.

Certifications

Hot Searches