- Product Details

- {{item.text}}

Quick Details

-

Brick size:

-

400*100*200 mm, 400*120*200 mm, 200*100*60 mm, 300*150*100 mm, 400*150*200 mm, 240*115*90 mm, 200*200*60 mm, 150*150*100 mm, Other, 400*200*200 mm, 230*220*115 mm, 250*120*90mm, 250*120*65mm

-

Place of Origin:

-

Shaanxi, China

-

Brand Name:

-

baoshen

-

Voltage:

-

380v

-

Dimension(L*W*H):

-

6500*2300*2400mm

-

Weight (KG):

-

11000 kg

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Body of extruder:

-

steel

-

Guarantee:

-

1 year

-

Plasticity index of raw material:

-

7-15

-

Moisture water content:

-

Moisture water content

-

Drying linear shrinkage rate(%):

-

3-8

-

Loss on ignition(%):

-

3-15

-

services:

-

Before-sale services,In-Sale services,After-sale services

-

Equipments:

-

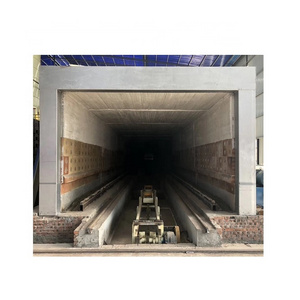

brick making mchine,dryer/ kiln,tunnel kiln

-

Building:

-

build brick dryer, hoffman kiln,tunnel kin

Quick Details

-

Type:

-

Hollow Block Making Machine, Interlock Block Making Machine, clay brick factory, red brick making machine, red brick making machinery

-

Brick Raw Material:

-

mud

-

Production Capacity (Pieces/8 hours):

-

10000-16000 pcs per hou, 16000-30000 pcs per hou

-

Brick size:

-

400*100*200 mm, 400*120*200 mm, 200*100*60 mm, 300*150*100 mm, 400*150*200 mm, 240*115*90 mm, 200*200*60 mm, 150*150*100 mm, Other, 400*200*200 mm, 230*220*115 mm, 250*120*90mm, 250*120*65mm

-

Place of Origin:

-

Shaanxi, China

-

Brand Name:

-

baoshen

-

Voltage:

-

380v

-

Dimension(L*W*H):

-

6500*2300*2400mm

-

Weight (KG):

-

11000 kg

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Body of extruder:

-

steel

-

Guarantee:

-

1 year

-

Plasticity index of raw material:

-

7-15

-

Moisture water content:

-

Moisture water content

-

Drying linear shrinkage rate(%):

-

3-8

-

Loss on ignition(%):

-

3-15

-

services:

-

Before-sale services,In-Sale services,After-sale services

-

Equipments:

-

brick making mchine,dryer/ kiln,tunnel kiln

-

Building:

-

build brick dryer, hoffman kiln,tunnel kin

new clay brick making machinery kiln for firing ceramics vacuum extruder brick making machinery baoshen

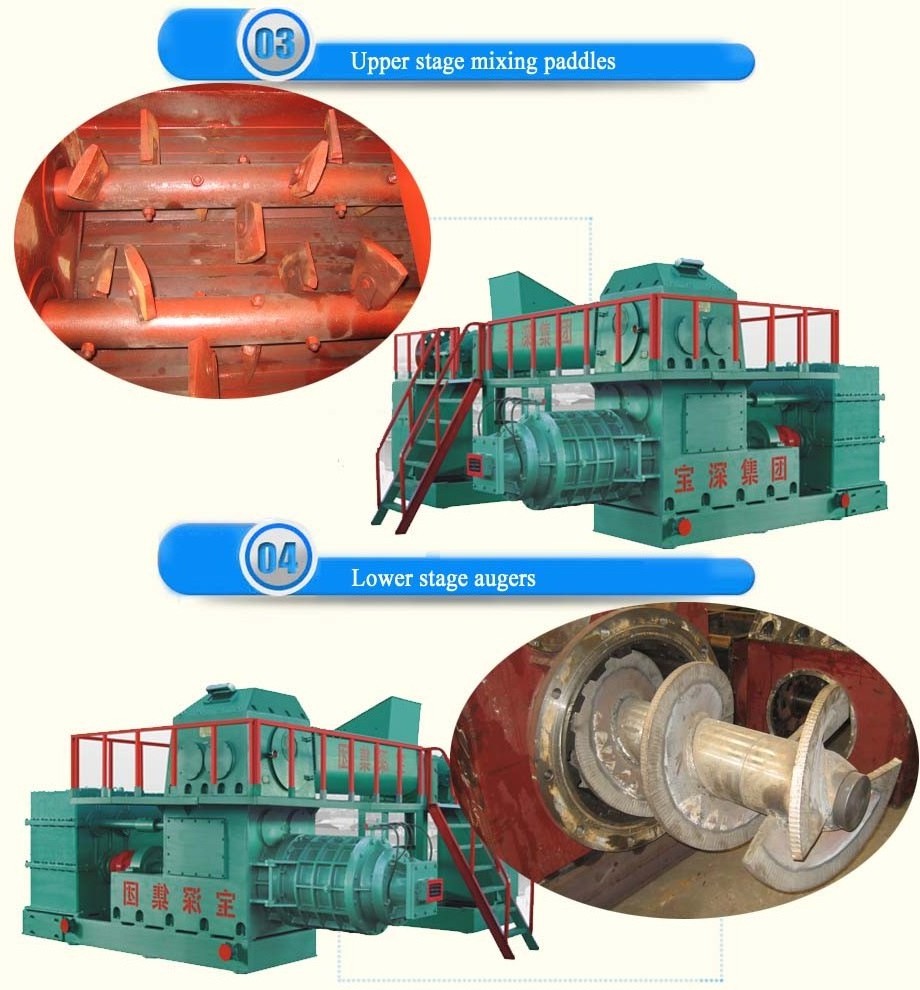

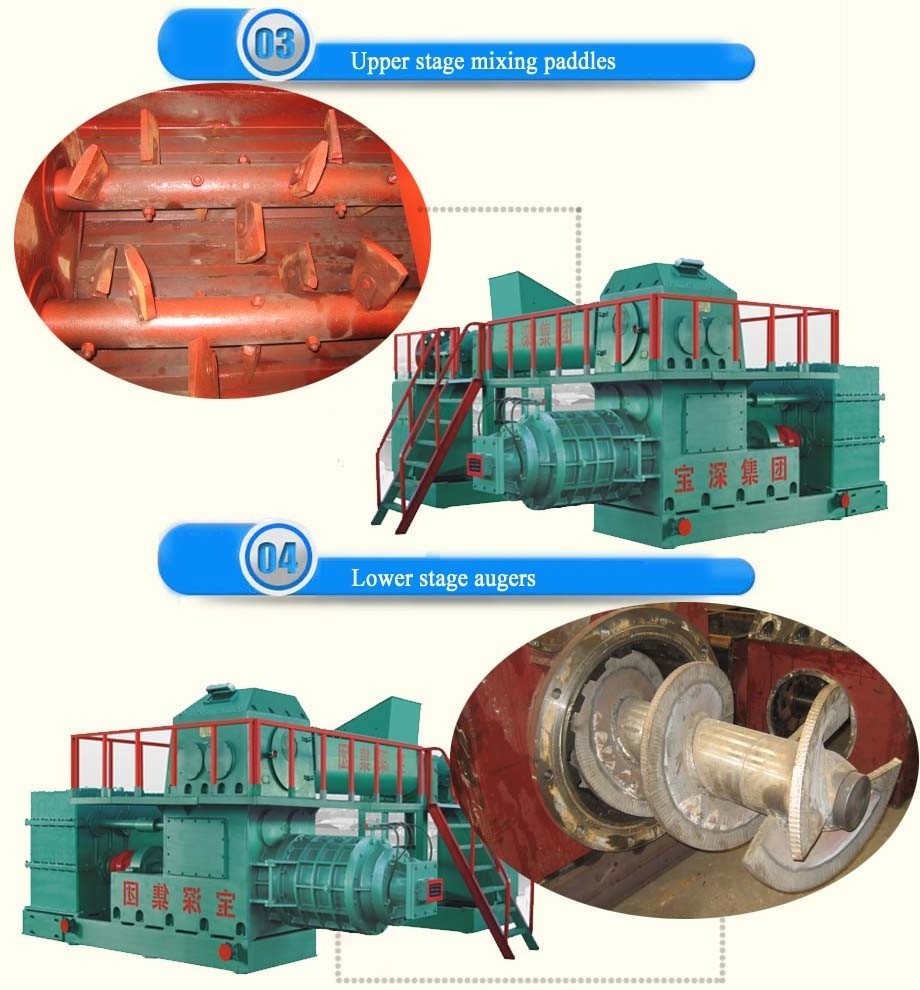

Build bes clay brick machine for clay brick making factory applies to clay, shale, coal gangue, fly ash, slag, mountain mud, silt, etc. to produce provisions cross-section of ordinary sol id bricks, hollow bricks, and other products.

Build best clay brick making factory with small tunnel dryer use the raw materials to make bricks.

1. Strong ability of machining

we have our own work shop that has the strong ability of machining means that we can produce all the spare parts of brick making machine independently, we will serve you the life long requirements of maintenance.

2. We take use of high technology during the production of the brick making machine so that increasing the working years of the machine, such as: frequency quenching of gear surface, spiral reamer sprays wear-resisting metal material , actual effect treatment of the complete case , axis heat tempering treatment

Best brick machine for clay brick factory

Advantage:

Best brick machine FOR clay brick factory main body is made from cast iron,main shaft and bearings one-time processing,good stability and long life service.

1)harden surface gear of Best service vacuum extruder clay brick machine was adopted in reducer, clutch are a component with own patent,without any shaking during working, even the extruder can working normal without foundation bolts.

2)t he steel material of shafts and gears in Best service vacuum extruder clay brick machine are adopt high quality carbon steel and alloy steel , the key parts are quenched and tempered treated so as to extend fly ash bricks making machine life.

3)The spiral cut reamer of Automatic Best service vacuum extruder clay brick machine adopt wear-resistance metal spray painting technology ; The upper stage mixing shaft, the cut reamer big shaft, the up-down body etc. are all passed the aging, quenching and tempering process .

Best clay brick production line

Baoshen brick machine for Build best clay brick making factory with small tunnel dryer ,clay brick production line

|

Technology Time |

Raw material procedure |

Forming procedure |

Drying procedure |

Burning procedure |

|

Annual working hour |

2400 |

2400 |

7200 |

7200 |

|

Annual working day |

300 |

300 |

300 |

300 |

|

Daily working hour |

8 |

8 |

24 |

24 |

clay brick making factory including fully automatic clay brick machine , brick dryer(small tunnel dryer & chamber dryer) for drying and brick kiln (hoffman kiln&tunnel kiln)for firing.

Baoshen Brick machine in one build and Build best clay brick making factory with small tunnel dryer including:

|

Brick making machinery |

|||||

|

No. |

Machinery |

Model |

Power (KW) |

Qty. |

Unit |

|

1 |

Box feeder |

XGD80×450 |

7.5* |

1 |

set |

|

2 |

Belt conveyor |

DS 60×10m |

4 |

1 |

set |

|

3 |

Primary roll crusher |

SGP70×50 |

15*×2 |

1 |

set |

|

4 |

Belt conveyor |

DS 60×10m |

4 |

1 |

set |

|

5 |

Double shaft mixer |

SJ360×36B |

55 |

1 |

set |

|

6 |

Belt conveyor |

DS 60×10m |

4 |

1 |

set |

|

7 |

High speed roll crusher |

GS80×60B |

22*×2 |

1 |

set |

|

8 |

Belt conveyor |

DS 60×16m |

5.5 |

1 |

set |

|

9 |

Double stage de-airing extruder |

JKB50/50C-32 |

55*+132* |

1 |

set |

|

10 |

Vacuum pump |

MH-2/150 |

7.5 |

1 |

set |

|

11 |

Air compressor |

VW-0.3/10 |

3 |

2 |

set |

|

12 |

Auto brick cutting system |

ZTP-E |

7.5 |

1 |

set |

|

13 |

Belt conveyor (waste brick return to mixer) |

DS 60×16m |

5.5 |

1 |

set |

|

14 |

Control panels |

1 |

set |

||

|

Total amount |

241.5 |

17 |

|||

Build best Clay brick making factory wtih small tunnel dryer area

The plant floor area is not less than 16,000m 2 .

The building area is not less than 1,300m 2 .

new clay brick making machinery kiln for firing ceramics vacuum extruder brick making machinery baoshen

video