- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

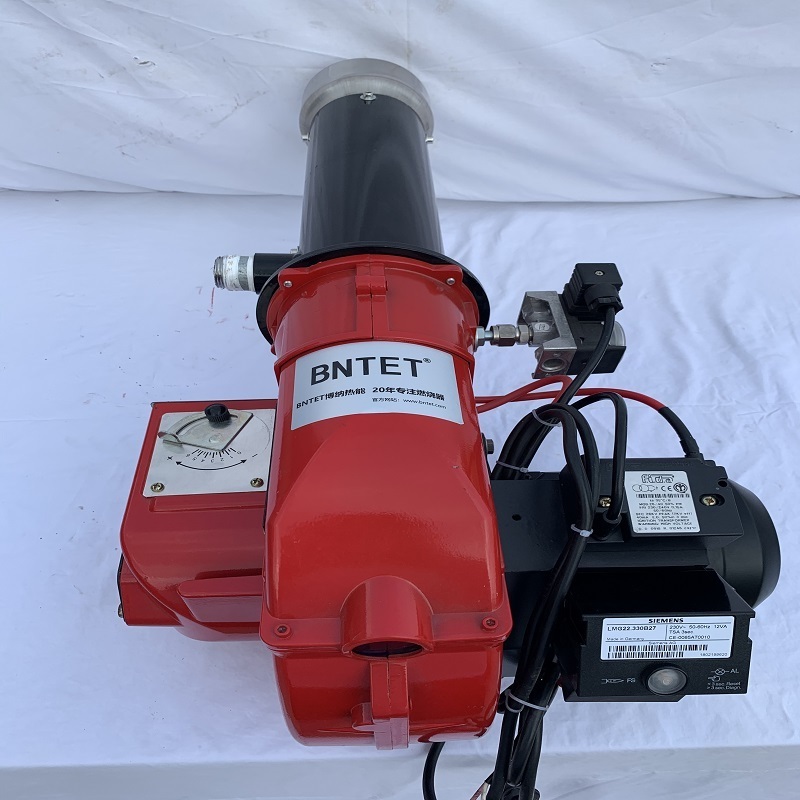

BNTET, BNTET

-

Power kW:

-

280 ~ 850

-

Model:

-

BNG 85 P

-

power supply:

-

3N AC 50Hz 380V

-

Motor power kW:

-

1.5

-

Package Dimensions L x W x H mm:

-

1250x900x800

-

weight kg:

-

95

-

Natural gas flow m³/h:

-

28 ~ 86

Quick Details

-

Type:

-

Oil Burner

-

Weight (KG):

-

95

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

BNTET, BNTET

-

Power kW:

-

280 ~ 850

-

Model:

-

BNG 85 P

-

power supply:

-

3N AC 50Hz 380V

-

Motor power kW:

-

1.5

-

Package Dimensions L x W x H mm:

-

1250x900x800

-

weight kg:

-

95

-

Natural gas flow m³/h:

-

28 ~ 86

Products Description

|

Product Name

|

Gas Burners

|

|

Fuel

|

Natural Gas, LPG, Coal Gas, Biogas, etc.

|

|

|

Boliers eqyuonebtm, hot blast stoves, drying applications, dryers, industrial kilns, furnaces, incinerators, calcining,equipment,ovens,spraying,ironing,power plants, metallurgy, steel, food processing and other industries that use thermal energy equipment.

|

|

Type

|

Burner Model

|

Gas/Oil Flow(m³/h)

|

Power

|

Power Supply

|

Motor Power

|

Modulation

|

||||||

|

Gas Burner

|

BNG 15

|

5--16

|

50-150

|

1N AC 50Hz 220V

|

0.18

|

One stage fire

|

||||||

|

|

BNG 35

|

9-36

|

90-360

|

1N AC 50Hz 220V

|

0.37

|

One stage fire

|

||||||

|

|

BNG 120 P

|

35-1202

|

350-1200

|

3N AC 50Hz 380V

|

1.5

|

Two stage fire

|

||||||

|

|

BNG 300 FC

|

65-300

|

660-2980

|

3N AC 50Hz 380V

|

7.5

|

Modulation

|

||||||

|

|

BNG 600 FC

|

80-545

|

800-5400

|

3N AC 50Hz 380V

|

15

|

Modulation

|

||||||

|

Contact us for more models and product details

|

|

|

|

|

|

|

||||||

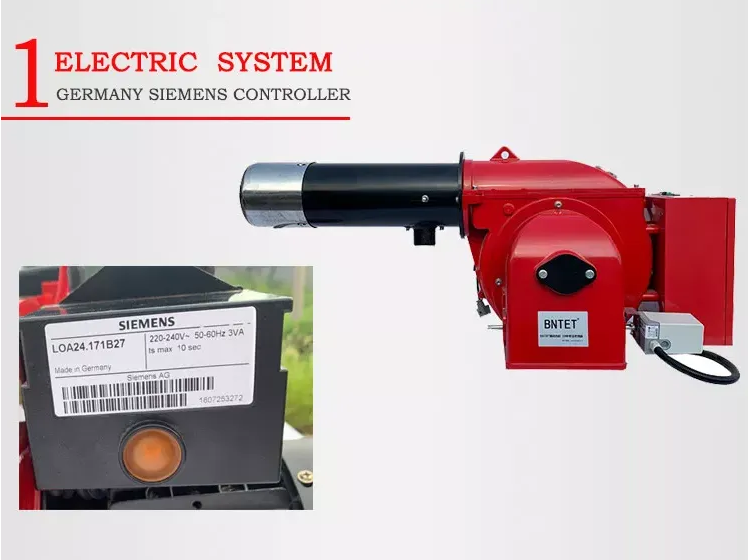

Gas burner definition:

I

t is a kind of equipment that converts substances into heat energy through the chemical reaction method of combustion—that is, air and fuel are mixed in an appropriate proportion through a premixing device to make them fully burnt. The burner is used to organize the gas combustion process and chemical The performance and quality of the device that can be converted into heat will directly affect the reliability and safety of the gas furnace (kiln) and other equipment!

Technological performance and structural descriptions:

·Ingle-stage operation (on/off)

·Air inlet with flow adjustment, sliding flange with dynamic closing damper and double flange pair, The position of the burner extending into the boiler can be adjusted

·Can adapt to any type of combustion chamber

·Air and gas are mixed in the burner

·By adjusting the combustion air and combustion head, the best combustion parameters can be obtained

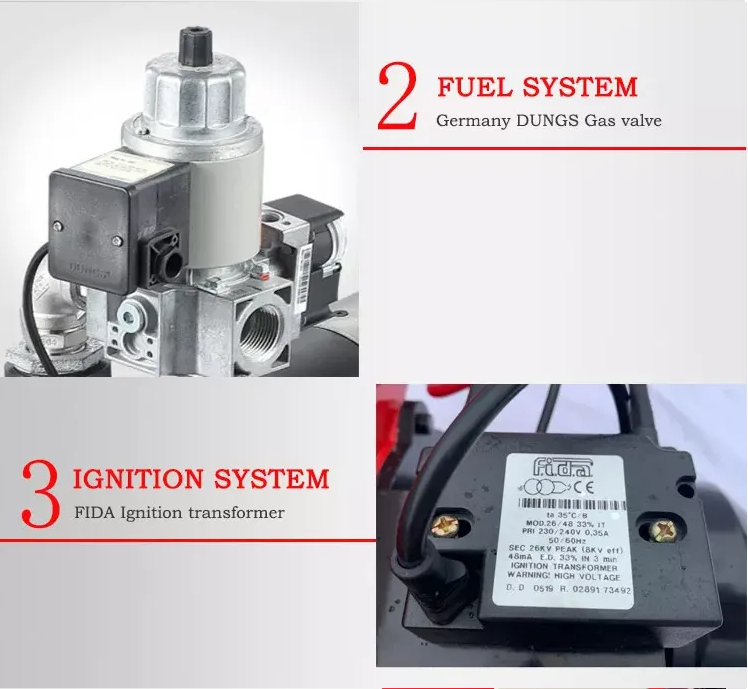

·Air pressure switch to ensure combustion air

·The gas valve group consists of operating valves, safety valves, minimum pressure switches, pressure regulators and gas filters (except for individual valve groups) to form a complete combination.

·Manually adjust the air flow

·Option of gas valve train with leak detection

·The ionization electrode detects fire

Product Advantages

Product Show

Other Type Burners

flexible system

Product packaging

Application

Hot Searches