1.High quality surface appearance

2.High productivity efficiency

3.Low cost

4.Environmental friendly

5.Lower abrasive consumption

6.Safe, no sparking

7.Less contamination

8.Not necessary to stop nearby jobs.

9.Removes scale for a paint ready surface.

10. Requires only a parking space

11. Does not warp metal

12. Leaves a primer-ready surface

13. Easy to clean up

14. Prevents rust for 72 hours

- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

Models

-

Weight (KG):

-

300

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Antai

-

Power:

-

Compressed Air

-

Dimension(L*W*H):

-

Models

-

Weight (KG):

-

300

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

Products Description

Main Features

Product Application

1. Our dustless blasting machines are mainly designed and integrated with the wide range of nozzles, wet blast attachments, internal pipe cleaning devices, dust free blasting heads, abrasive control device.

2. The dustless blasting machine is used for every filed in the world, such as, Automative, Marine, Reginery, Fleet vehicles, Graffiti removal, stripe Removal, Heavy equipment, Surface cleaning, Powder coating, Offshore, Wood restoration, Asbestos Abaement.

3. Dustless blasting recognizes the needs of the industry and our machines offer all the features that the professional use requires. All machines can be fitted with a well designed and proven single piece remote control dead man switch and silencer which significantly reduce labour cost, improve efficiency of abrasive, performance and safety.

4. The machines are constructed for a maximum 150 PSI working pressure. The pneumatic abrasive remote control valve can achieve operators to stop or start .

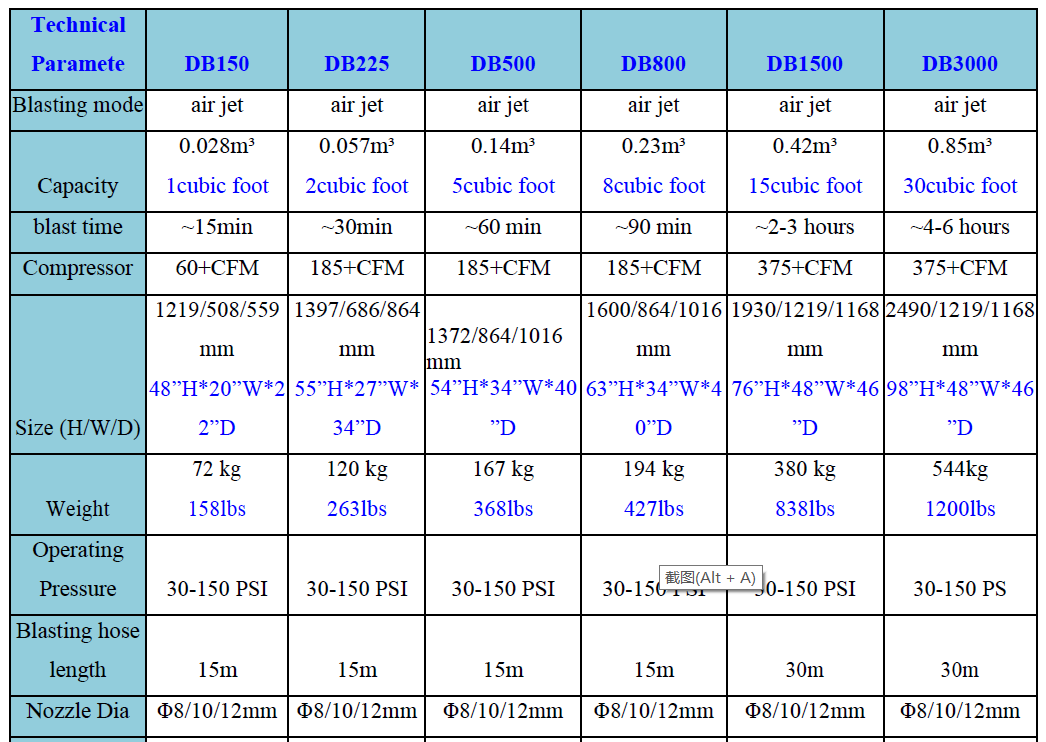

1. Technical Parameter

2. Requirement for air compressor

4-10 bar, 60-3755 CFM, 30-150 PSI, 0.2-1.0 Mpa

3. Includes

A. Blast hose(Inner diameter is ID25OD38mm or ID32OD48mm)

B. Deadman activator valve

C. Tungsten carbide nozzle(diameter is 8/10/12mm)

D. Fill funnel

E. Lifetime warranty on blast pot

B. Deadman activator valve

C. Tungsten carbide nozzle(diameter is 8/10/12mm)

D. Fill funnel

E. Lifetime warranty on blast pot

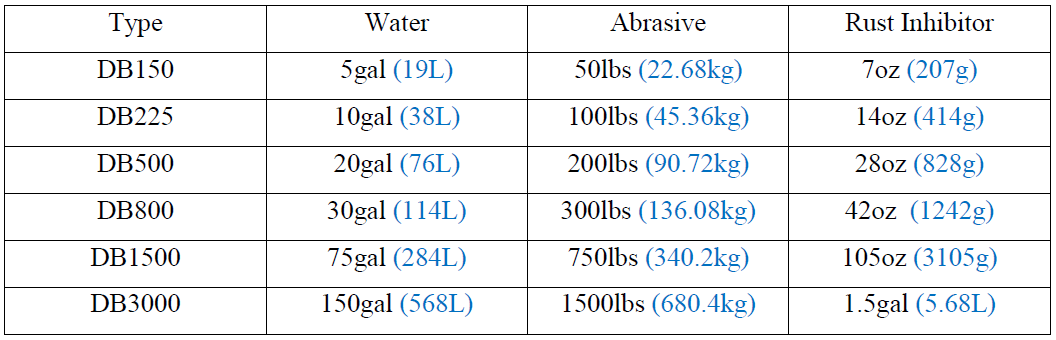

4. Consumables

Cleaning effect

Packing&Delivery

1.Equipment painting completed before shipment, With Stretch film to avoid rub off the surface paint, It can used wooden cases packaging according to users requirements.(Key parts such as electric cabinet with shockproof packaging material and then packed in wooden cases. )

2. We have 15 experienced engineers, With 108 skilled workers insure good quality of our machines and prompt delivery.

3.Meanwhile our company has a long-term cooperation with ACL, CSCL, CCNI, CNC, COSCO etc insure the goods to the port on time.

Machine details pictures

Certifications

Hot Searches