- Product Details

- {{item.text}}

Quick Details

-

Power:

-

1.75kw

-

Weight:

-

280 KG

-

Dimension(L*W*H):

-

1680*1200*1700mm

-

Function:

-

Extrusion

-

Control system:

-

PLC

-

Material:

-

Stainless Steel 304

-

Usage:

-

Food Industry Equipment

-

Sizzle of nozzle:

-

10-70mm(customized)

-

Type:

-

Fully Automatic

-

MOQ:

-

1 Set

-

Instock:

-

Yes

-

Advantage:

-

Easy Installation

-

Packing:

-

Wodoen Case

Quick Details

-

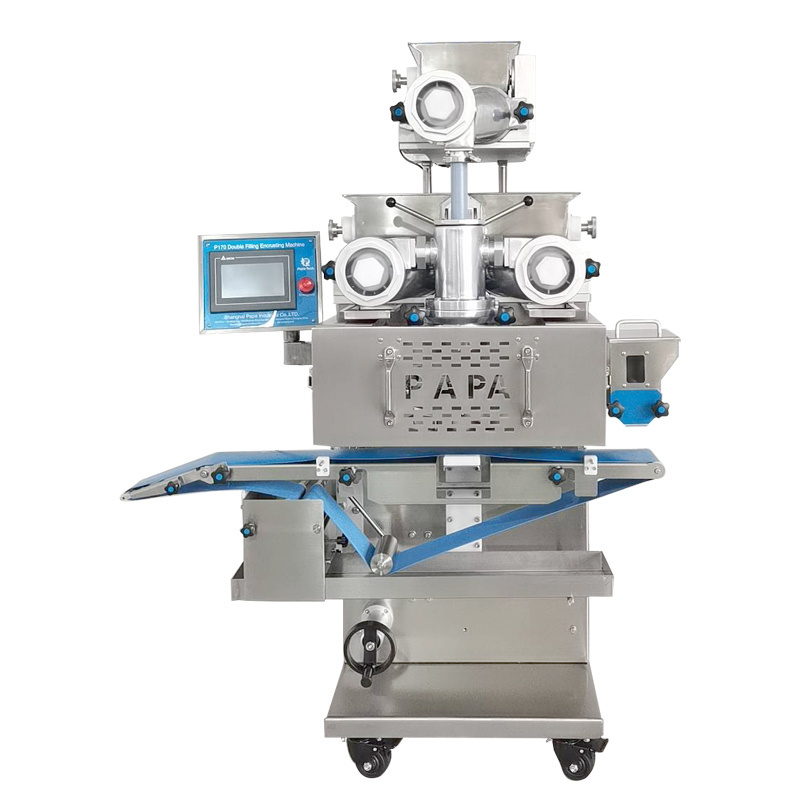

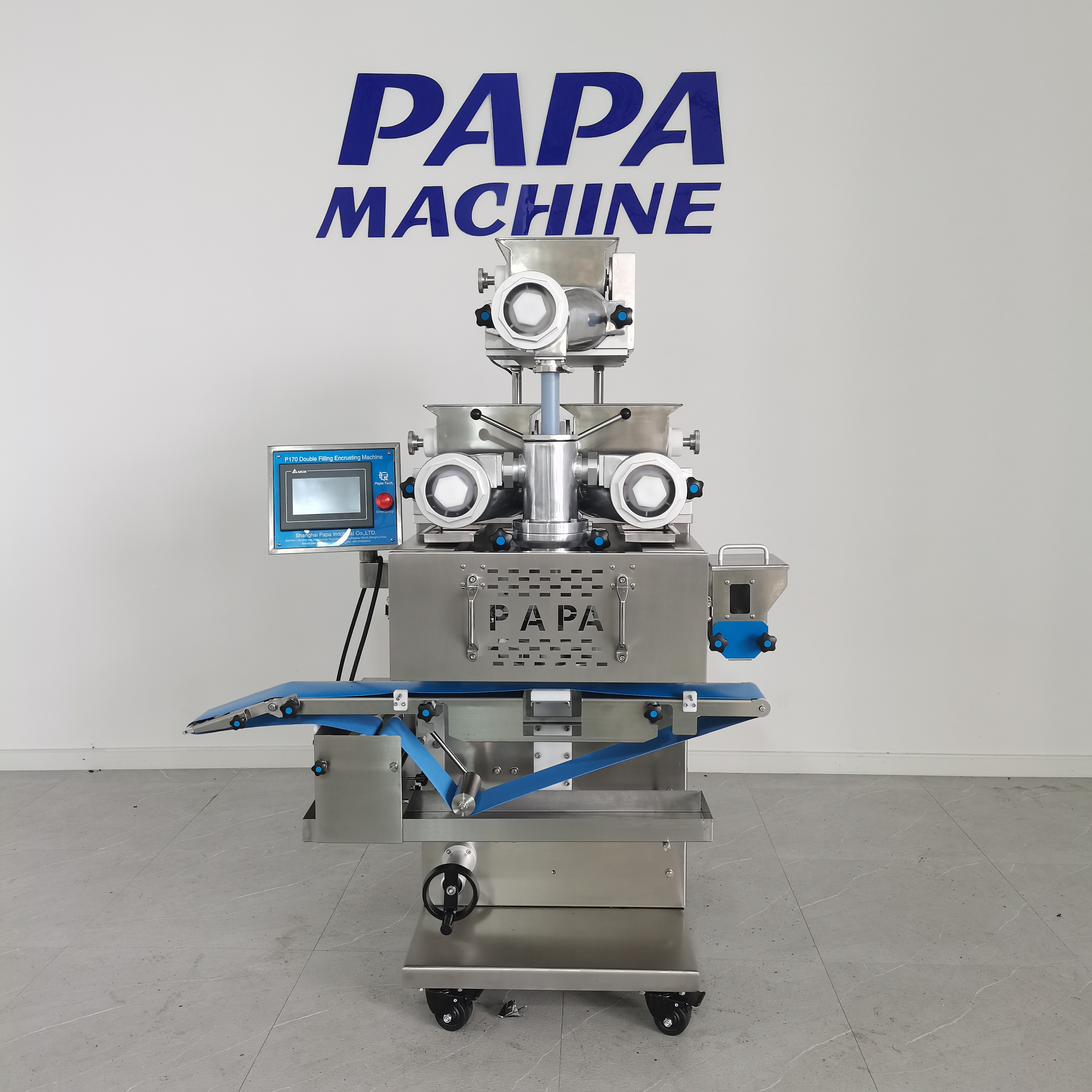

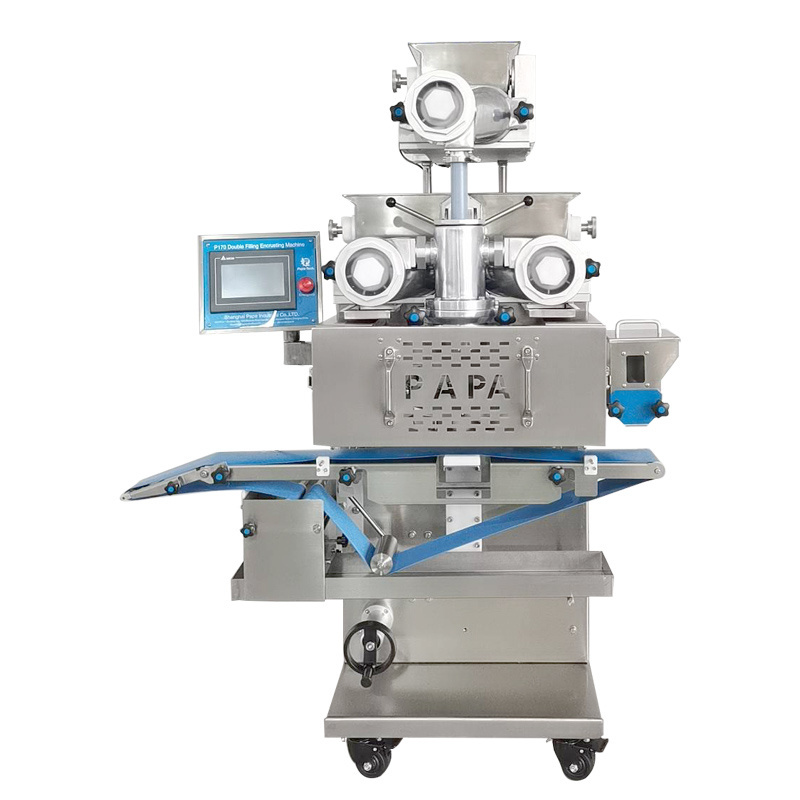

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

PAPA

-

Voltage:

-

220V

-

Power:

-

1.75kw

-

Weight:

-

280 KG

-

Dimension(L*W*H):

-

1680*1200*1700mm

-

Function:

-

Extrusion

-

Control system:

-

PLC

-

Material:

-

Stainless Steel 304

-

Usage:

-

Food Industry Equipment

-

Sizzle of nozzle:

-

10-70mm(customized)

-

Type:

-

Fully Automatic

-

MOQ:

-

1 Set

-

Instock:

-

Yes

-

Advantage:

-

Easy Installation

-

Packing:

-

Wodoen Case

Machine description:

P188 Automatic encrusting machine can produce bakery products: Cantonese-style moon cakes, pineapple cakes, soft cookies with soft core, mixed egg yolk cakes, wedding eggs, open small pizza, peach cakes, small volcano-shaped cookies, mung bean cakes, coconut silk balls, handmade cookies, panda cookies , e-shaped cakes, mosaic biscuits, pumpkin cakes, Cantonese-style wife cakes, jujube cakes (two-color burst cookies, heart-flowing moon cakes, horseshoe cakes, yin and yang sandwich cakes, brushed pineapple cakes, gradient moon cakes, covered moon cakes, whole egg yolk mooncake)

Cooking products: snowy cakes, crystal cakes, green balls, mochi, long strips of mochi, glutinous rice cakes, Tiaotou cakes, donkey rolls, big glutinous rice balls, Dafu (marshmallow mochi, two-color mochi, stuffed green group)

Breakfast products: pocket cake forming, glutinous rice cake forming, beef cake,

Fish ball products: fish balls, meat balls, crystal buns, shrimp cakes, cheese rice cakes, crispy bananas, pumpkin cakes, brown sugar glutinous rice cakes (two-color fish balls, two-color crystal bags, yin-yang fish balls)

| Machine model | P188 |

| Capacity | 20-120/min |

| Product weight | 20-250 grams |

| Voltage/power | 3kw |

| Dimensions | 1680*1200*1700mm |

| Machine weight | 400KG |

| Material: | SUS304 |

P188 VS . P160 Upgrade Points

1. The inner hole of the connecting pipe and the connecting seat at the connection between the rectifier and the main body is enlarged to reduce the damage of raw materials and discharge the materials faster and more smoothly.

2. The main body is enlarged, the accessories are reduced, there is no dead angle, and it is easy to clean. And there is enough internal space when the quadruple filling is added later, the output is smoother, and the production capacity is higher than that of P160.

3. The inner stuffing tube adopts Rheon's technology, and the material is discharged smoothly, and the material will not be eccentric, and the center ring is not needed. The P160 relies on the center ring to fix the eccentricity problem. It will damage the raw material. The material is cast aluminum as a whole and is not easy to damage.

4. The inner filling tube is fixed by pulling up, and the inner filling tube can be removed without dismantling the four fixed die head bolts, thus saving cleaning and disassembly time.

5. The upper machine board of the triple stuffing machine has reserved holes for egg yolk beating, and the egg yolk beating device can be directly installed later to achieve egg yolk beating, and the egg yolk beating position is fixed on the upper machine board, which is more stable than P160.

6. The cutter adopts the vertical up and down movement cutting method, the incision is parallel to the conveyor belt, the filling effect is more uniform, and the stability of the weight is better guaranteed (the motor is imported from Japan with brakes, which is the same brand as Rheon). The motor Brand Nissei. P160 is a swing structure.

7. The cutting knife, the lifting of the cutter head and the upper top are all made of sheet metal processing structure, the transmission is stable and the noise is small, and the machine will not shake when the machine is turned on at 100 pieces/minute. The power of the 160 cutter head adopts a sheet metal structure. 160, drive a little faster and the machine shakes, because the internal cutter head transmission is a swing structure.

8. The noise of the upper cam is small, and the adjustment of the upper cam is simple and convenient.

9. The German igus corner bearing is used at the knife edge of the conveyor belt, which has a smaller friction force than the 160 sheet metal crushing edge, thus greatly improving the life of the belt.

10. Stirring teeth and copper lining are processed with new materials, which are more wear-resistant, and do not produce black oil or leak materials.

11. The fixed die head of the outer mold is not easy to damage the wire teeth when cleaning the inner teeth, and the disassembly wrench is equipped with a hexagonal hole type, which is easier to disassemble.

12. The touch screen is placed on the left, so that the left hand can control the touch screen and the right hand can pick up the product during debugging.