- Product Details

- {{item.text}}

Quick Details

-

Bending Precision (Deg):

-

0.1

-

Place of Origin:

-

Anhui, China

-

Brand Name:

-

SXZG

-

Power (kW):

-

4

-

Weight (KG):

-

1500

-

Product name:

-

Mandrel Pipe Bender

-

Application:

-

Pipes Processing

-

Usage:

-

Pipe Tube Bending

-

Material:

-

Cr12Mov

-

After-sales Service Provided:

-

Free spare parts

Quick Details

-

Machine Type:

-

CNC

-

Bending Radius (mm):

-

10 - 180

-

Max. Bending Angle (Deg):

-

190

-

Bending Precision (Deg):

-

0.1

-

Place of Origin:

-

Anhui, China

-

Brand Name:

-

SXZG

-

Power (kW):

-

4

-

Weight (KG):

-

1500

-

Product name:

-

Mandrel Pipe Bender

-

Application:

-

Pipes Processing

-

Usage:

-

Pipe Tube Bending

-

Material:

-

Cr12Mov

-

After-sales Service Provided:

-

Free spare parts

Product Overview

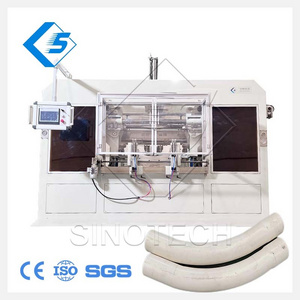

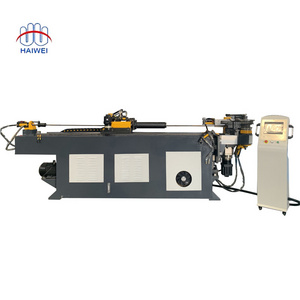

1. Fully automatic and CNC pipe bending machine.

2. Exhaust tube bending machine equipped with servo motor programmable axis,2axis 3 axis, 4 axis or 5 axis...

3. Feeding: servomotor drive; Rotation: servomotor drive

4. Bending: hydraulic and encoder control; Servomotor with reducer.

5. 2inch pipe bending machine use imported hydraulic system and PLC unit or IPC.

6. Automatic lubrication system for moving areas.

7. Self-diagnostic system, detecting the error immediately.

8. Multiple groups pipe-bending information storage.

9. Electric cabinet cooling fan and the hydraulic cooling system ensure the equipment long-time work stably under the

hightemperature.

10. Touch screen and human/machine interface control provide user friendly operations

2. Exhaust tube bending machine equipped with servo motor programmable axis,2axis 3 axis, 4 axis or 5 axis...

3. Feeding: servomotor drive; Rotation: servomotor drive

4. Bending: hydraulic and encoder control; Servomotor with reducer.

5. 2inch pipe bending machine use imported hydraulic system and PLC unit or IPC.

6. Automatic lubrication system for moving areas.

7. Self-diagnostic system, detecting the error immediately.

8. Multiple groups pipe-bending information storage.

9. Electric cabinet cooling fan and the hydraulic cooling system ensure the equipment long-time work stably under the

hightemperature.

10. Touch screen and human/machine interface control provide user friendly operations

FEATURES AT A GLANCE

PRODUCT SPECIFICATIONS

|

Model

|

Unit

|

DW38CNC-2A-1S

|

|

|

|

|

Max bending capability

|

Mm

|

38*2

|

|

|

|

|

Max bending radius

|

Mm

|

R180

|

|

|

|

|

Min bending radius

|

Mm

|

According to pipe diameter

|

|

|

|

|

Max bending angle

|

°

|

190

|

|

|

|

|

Max feeding length

|

Mm

|

2200

|

|

|

|

|

Bending speed

|

°/s

|

150

|

|

|

|

|

Rotary speed

|

°/s

|

200

|

|

|

|

|

Feeding speed

|

mm/s

|

1000

|

|

|

|

|

Motor power

|

kw

|

4

|

|

|

|

|

Max oil pressure

|

Mpa

|

12

|

|

|

|

PRODUCT CONFIGURATION

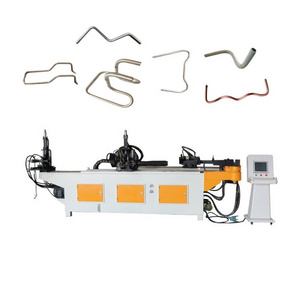

Workpiece Samples

Packaging and Delivery

FAQ

Q1: Are you trading company or manufacturer ?

A1: We are manufacturer of pipe tube processing.

Q2: How long is your delivery time?

A2: The standard model is 10-15 days, the customized model is 30-60 days.

Q3: How to choose the model of machines?

A3: -Max.outside diameter

-Wall thickness range

-Bending radius (CLR)

-Pipe material:

-Products workpiece drawings if you have.

Q4: What is your term of payment ?

A4: 30% T/T in advance, the balance before shipment.

Q5: How does your factory do regarding quality control?

A5: Our core components adopt international brands, Mitsubishi servo motors, Mitsubishi PLC, Schneider, Omron electrics. And there is a QR code to check the authenticity. Our processing equipment is very advanced and complete.

Q2: How long is your delivery time?

A2: The standard model is 10-15 days, the customized model is 30-60 days.

Q3: How to choose the model of machines?

A3: -Max.outside diameter

-Wall thickness range

-Bending radius (CLR)

-Pipe material:

-Products workpiece drawings if you have.

Q4: What is your term of payment ?

A4: 30% T/T in advance, the balance before shipment.

Q5: How does your factory do regarding quality control?

A5: Our core components adopt international brands, Mitsubishi servo motors, Mitsubishi PLC, Schneider, Omron electrics. And there is a QR code to check the authenticity. Our processing equipment is very advanced and complete.

Q6: How is the training and after sales service?

A6: Training: Training CD or Manuals are available. We have many after-sales engineers who can speak English and provide free online services for life, including free teaching and training. We can train 3-5 skilled operators for you, so you don’t have to worry about the machine not being used normally due to employee resignation. After sale service: this shall be done by the seller. Seller will provide all kinds of technical support to the buyer by telephone, fax or email free of charge. After one-year guarantee period, we assure you life-long maintenance.

A6: Training: Training CD or Manuals are available. We have many after-sales engineers who can speak English and provide free online services for life, including free teaching and training. We can train 3-5 skilled operators for you, so you don’t have to worry about the machine not being used normally due to employee resignation. After sale service: this shall be done by the seller. Seller will provide all kinds of technical support to the buyer by telephone, fax or email free of charge. After one-year guarantee period, we assure you life-long maintenance.

Recommend Products

Hot Searches