- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V/380V/440V

-

Dimension(L*W*H):

-

790*785*790mm

-

Weight:

-

150 KG

-

Marketing Type:

-

Hot Product 2024

-

Name:

-

Mining Gold Centrifugal Concentrator

-

Processed materials:

-

Chrome Iron Ore

-

Keywords:

-

Centrifugal Gold Concentrtor,Centrifugal Concentrator

-

Feeding size:

-

0-3mm

-

Main products:

-

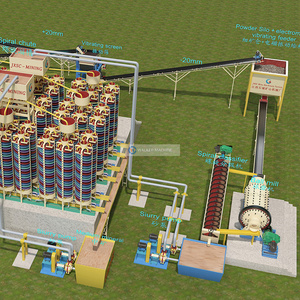

Mining feeder,Jaw Crusher,Ball Mill,Spiral chute,Shaking table etc

-

Recovery rate:

-

98%~99%

-

Price:

-

Competetive (Can Negotiate)

-

Machine type:

-

STL-20,STL-30,STL-60,STL-80,STL-100

-

certificate:

-

CE,ISO

-

factory visit:

-

warmly welcomed

Quick Details

-

Production Capacity:

-

0.2-120t/h

-

Place of Origin:

-

Jiangxi,China

-

Brand Name:

-

Hengchang Centrifugal Concentrator

-

Voltage:

-

220V/380V/440V

-

Dimension(L*W*H):

-

790*785*790mm

-

Weight:

-

150 KG

-

Marketing Type:

-

Hot Product 2024

-

Name:

-

Mining Gold Centrifugal Concentrator

-

Processed materials:

-

Chrome Iron Ore

-

Keywords:

-

Centrifugal Gold Concentrtor,Centrifugal Concentrator

-

Feeding size:

-

0-3mm

-

Main products:

-

Mining feeder,Jaw Crusher,Ball Mill,Spiral chute,Shaking table etc

-

Recovery rate:

-

98%~99%

-

Price:

-

Competetive (Can Negotiate)

-

Machine type:

-

STL-20,STL-30,STL-60,STL-80,STL-100

-

certificate:

-

CE,ISO

-

factory visit:

-

warmly welcomed

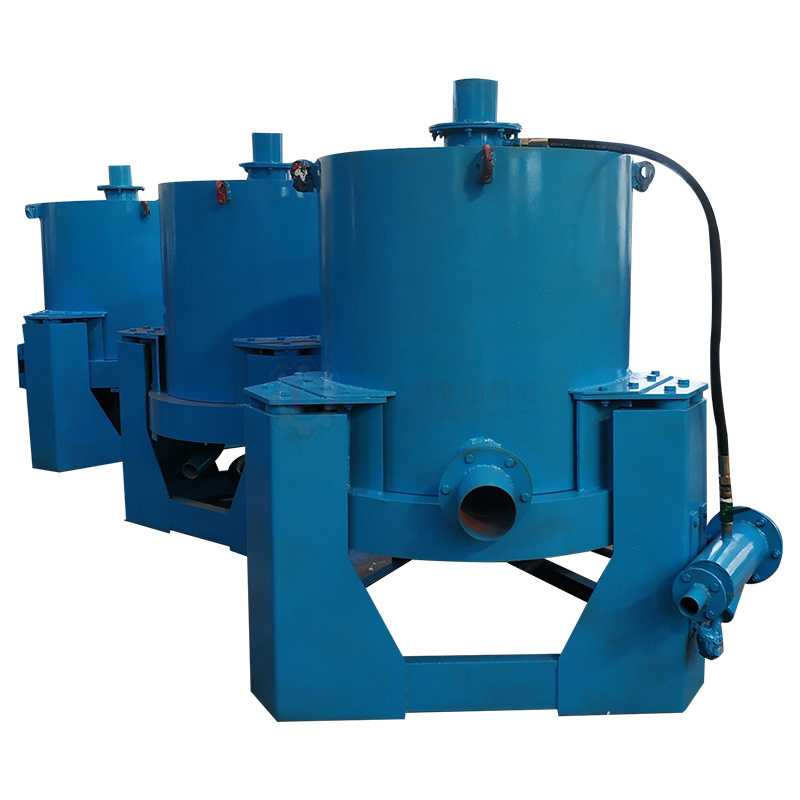

Small Scale Gold Mining Equipment Beneficiation Copper Chrome Ore Blue Centrifugal Concentrator Price

Hengchang Gold Mineral Concnetrator is a kind of gold gravity equipment. It can be used not only for placer gold mining, but also for hard rock mining to recover the natural gold, replacing amalgamation. It is also used to recover gold from the old tailings.If you want to buy mining equipment, choose Hengchang, we must ensure that you are satisfied.

Products Description

Gold centrifugal concentrator

also called knelson concentrator is a new type of gravity concentration equipment, used in the gold mining industry. It is used for the recovery of fine particles of free gold, meaning gold that does not require gold cyanidation for recovery.There are have Five models are available. Application shows that the recovery can be as high as 90%, especially for the case in recovering the natural gold in lode ore with 65% of the ore having a milling size of 0. 074mm, the recovery for the natural gold is expected up to 98%, For that natural gold of 0.004mm in particle size, the recovery is 97%. The cleaning up cycle is 1~4 hours,and the upgrade ratio is up to 1,000 times. The equipment is patented in China.

Processing Materials:

Gold, silver, platinum, tin, tungsten, lead, antimony, chrome, titanium etc.

Product Working Principle

The hollow shaft of

gold centrifugal concentrator

can be driven by electrical motor transmission part through belt driving, making the rotation inner sleeve rotate in a high speed to produce centrifugal force. The slurry will be fed into the rotation inner sleeve through feeding pipe, and the slurry particle will be separated under the action of centrifugal force field. The heavy mineral will be remained in the cell guide of rotation inner sleeve, and the light mineral will be discharged through the tailings launder. After one shift work and stop running, the concentrate will be discharged through the concentrate discharge outlet.

Product Features

1.High concentrating ratio and high recovery.

2.Steady recovery performance.

3.Center discharge design for fast, secure concentrate removal.

4.Environmentally friendly (requires no chemical additives or reagents).

5.Low water and electricity requirements.

6.Low production costs, durable wear parts, minimal maintenance requirements.

7.Compact design requiring less space, easy merged into the existing mining processing.

2.Steady recovery performance.

3.Center discharge design for fast, secure concentrate removal.

4.Environmentally friendly (requires no chemical additives or reagents).

5.Low water and electricity requirements.

6.Low production costs, durable wear parts, minimal maintenance requirements.

7.Compact design requiring less space, easy merged into the existing mining processing.

Product Paramenters

|

Model

|

STL-20

|

STL-30

|

STL-60

|

STL-80

|

STL-100

|

|

Capacity (t/h)

|

0.2-0.6

|

2-3

|

10-20

|

35-45

|

60-120

|

|

Feeding size (mm)

|

0-3

|

0-4

|

0-6

|

0-6

|

0-6

|

|

Feeding density (%)

|

0-50%

|

0-50%

|

0-50%

|

0-50%

|

0-50%

|

|

Backwash water (t/h)

|

1.5-2

|

4-6

|

10-15

|

17-25

|

40-60

|

|

Output(kg/time)

|

2-3

|

10-20

|

30-40

|

60-70

|

70-80

|

|

Motor power (kw)

|

0.75

|

1.5

|

5.5

|

11

|

18.5

|

|

Revolution(r/min)

|

800

|

600

|

460

|

400

|

360

|

|

Pressure water (Mpa)

|

0.04

|

0.12

|

0.25

|

0.35

|

0.4

|

|

Dimension (mm)

|

790x785x790

|

1180x1140x1250

|

1970x1670x1750

|

2300x1800x2200

|

2500x2000x2400

|

|

Weight (kg)

|

145

|

400

|

1300

|

2000

|

2500

|

Successful Case

Gold centrifugal concentrator in Malaysia

For placer gold mining.

Gold centrifugal concentrator in Zambia

For placer

tine ore.

Gold centrifugal concentrator in Dubai

For recover the natural gold.

Gold centrifugal concentrator in Australia

For placer

chrome ore.

Gold centrifugal concentrator in Tanzania

For placer

rock gold ore

Gold centrifugal concentrator in South Africa

For placer

platinum

ore.

Gold centrifugal concentrator in Mali

For recovery of fine particles of free gold

Gold centrifugal concentrator in China

For recover gold from the old tailings.

Packing & Delivery

Hot Searches