Drilling fluids shear pump mud shearing pump machine for shearing polyers and clays process

-

Transport Package:

-

Wooden Pakage

-

Specification:

-

JQB5×6-10

-

Trademark:

-

JINGZHENG

Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Origin:

-

China

-

Certification:

-

ISO 9001:2000 ISO 9001:2008 Other

-

Power Source:

-

Electric

-

Operation Pressure:

-

Atmospheric Pressure

-

Material:

-

Alloy

-

Type:

-

Sand Pump

-

Payment:

-

L/C T/T Other

-

Export Port:

-

Tianjin shanghai

-

Output:

-

50000 pics/year

-

Model NO:

-

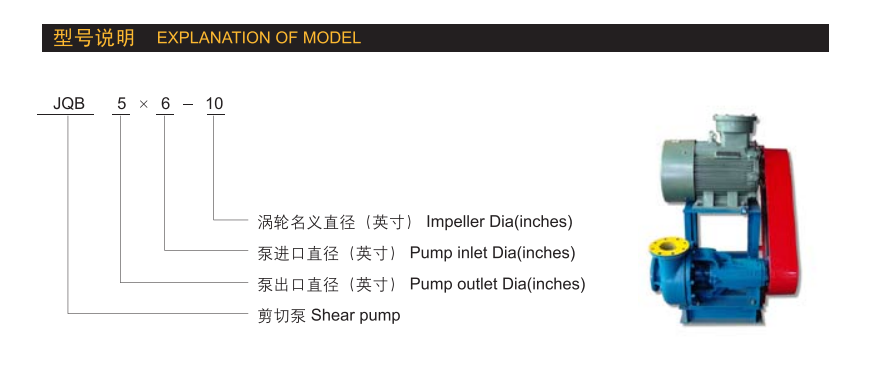

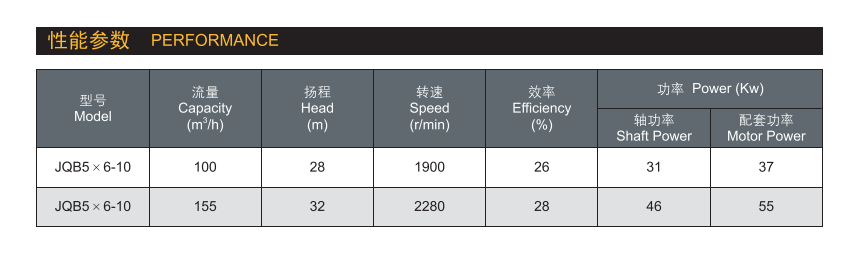

JQB5×6-10

Quick Details

PRODUCT INTRODUCTION

Shear Pumps are an essential piece of equipment and part of the mud cleaning process. It is a mechanical device that is used for the purpose of pumping liquid and semi-solids. The principle used for the device to work is the high shear force that is produced in between the working head. A Shear Pump simply uses a high-speed rotor powered by an electric motor. They work on the fluid, creating a flow and shear.

The shear pumps have a hydration system attached, which quickly cuts and dilutes hydrated polymers. A unique mechanical composite steel technology is used in the shear pump to ensure that there is no leakage. The high wear-resistant metallic materials are used for the impellers and the casing, which prolongs their service life. The Impeller is structured in a way that is according to the principle of fluid mechanics and results in increased liquidity. The low shear force results in the efficient working of this Shear Pump.

MAIN FEATURES OF SHEAR PUMP

- Impeller

- Hydration system

- High-speed rotor

- Electric motor

- A power device

The JQB5×6-10 Shear Pump generation is uniquely design pump for shearing polymers and clays. To improve the drill fluid properties, the polymers or clays should be highly sheared before adding to the drill fluid system, If not sheered, the polymers maybe jam the strainer and will result in losing amount of polymer and increasing drilling costs, and the large-size solids in the drill fluid will harden and difficult to clear away as well. The JOB5 × 6-10 shear pump has proven best for applying the high shear necessary to hydrate polymers and clays and to their best properties. Using the JOB5 ×6-10 Shear Pump reduces the bentonite clay needed by 33% or more and polymer needed by 15% or more. It also improves fluid loss and filter cake, builds gel strength, and low shear rate viscosity to better hold up solids

EXPLANATION OF SECTIONAL

The JQB5×6-10 shear pump adopts a set of compound seal for no leakage at stuffing box. Inside pump is a 300 series stainless steel turbine containing 44 nozzles, four scoops and shear plate. Fifty(50)% of the fluid is sheared twice each time thorugh the pump.This turbine shear pump is mounted on a special base with belts and sheaves to drive pump, OSHA type belt guard and a 75HP(55KW) explorsion U/L approved electric motor, 460 volt, 3 phase 60 cycle. Included is a special hopper(ZHP150) with nozzle sized for this application and one mud kit as a package in order to build a complete shear and hydration system. The pump is designed to give longer service life through the improved shaft seal.

WARNING

This pump can not be used on active mud system since it will shesr drill solids and barite,these solids will also damage pump very quickly.