- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

110V 50Hz

-

Power:

-

120w

-

Dimension(L*W*H):

-

1860*820*850mm

-

Weight:

-

200

-

Name:

-

Chemical reactor mixing tank

-

Function:

-

Mixing machine

-

Keywords:

-

Chemical industry reactor

-

Related machines:

-

Blender/chemical reactor/ mixing tank

-

Finally products:

-

Hot Melt Glue Sticks/ Pillow/Granules

-

Usage:

-

Paste/DIY

-

Advantage:

-

High Efficiency/ Easy Control/ Long Working Life

-

PACKING:

-

Wooden Case

-

After-sales Service Provided:

-

Engineers/Installation and commissioning

Quick Details

-

Capacity:

-

8000L, 10L-5000L

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

JCT

-

Voltage:

-

110V 50Hz

-

Power:

-

120w

-

Dimension(L*W*H):

-

1860*820*850mm

-

Weight:

-

200

-

Name:

-

Chemical reactor mixing tank

-

Function:

-

Mixing machine

-

Keywords:

-

Chemical industry reactor

-

Related machines:

-

Blender/chemical reactor/ mixing tank

-

Finally products:

-

Hot Melt Glue Sticks/ Pillow/Granules

-

Usage:

-

Paste/DIY

-

Advantage:

-

High Efficiency/ Easy Control/ Long Working Life

-

PACKING:

-

Wooden Case

-

After-sales Service Provided:

-

Engineers/Installation and commissioning

Stainless steel liquid mixing tank agitator chemical reactor

Reaction Vessel : The primary component of a chemical reactor is the reaction vessel, where the chemical reaction takes place.

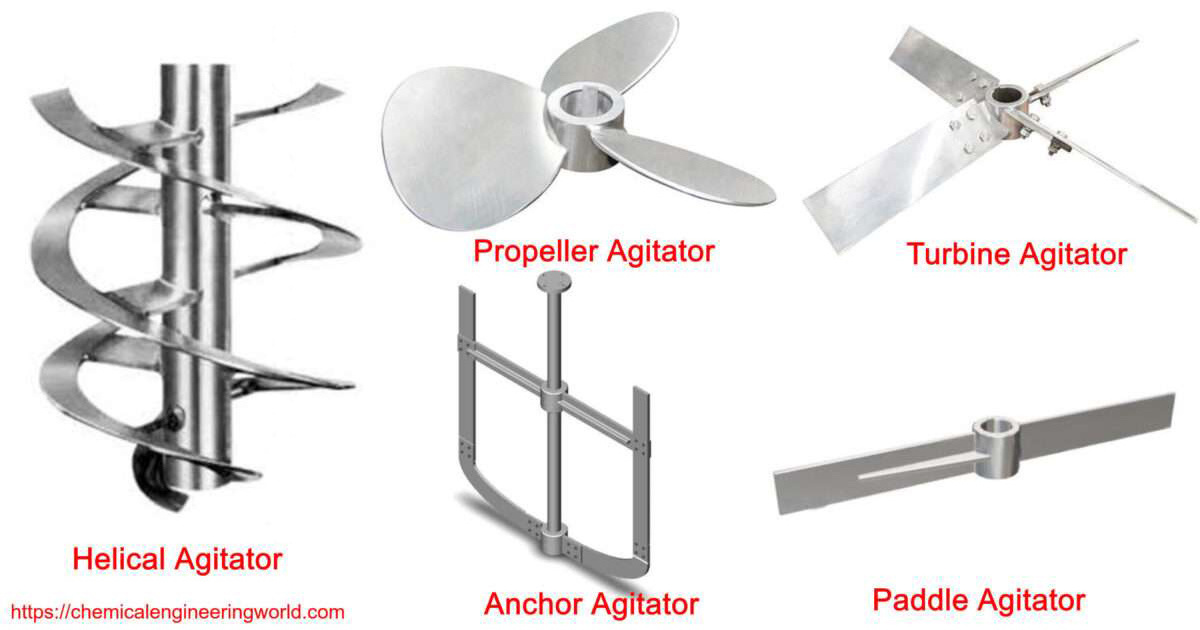

Stirring or Mixing System: Many chemical reactions require thorough mixing of reactants to ensure uniform contact and reaction rates. Agitators, impellers, or mechanical stirrers are often used to achieve this mixing.

A chemical reactor can produce a wide range of products depending on the specific chemical reaction and starting materials used. These products span various industries and applications:

Chemical Products: Including various compounds, polymers and fertilizers.

For example:hot melt adhesive,resin, silicone oil, PU glue and so on.

Petrochemical Products: Such as fuels, petrochemical feedstocks, and plastics.