Function: support rolled plate and strip tension for erw pipe mill production line, by the frame, main shaft, increases of drum, brake.

There are 3 types: pneumatic, hydraulic and manual.

- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Sinopower

-

Voltage:

-

Customized

-

Power:

-

25 Kw ~ 600 Kw

-

Dimension(L*W*H):

-

Base on customer's land size

-

Weight:

-

60 kg, 45 tons ~ 90 tons

-

Production name:

-

ERW pipe mill production line

-

Pipe diameter:

-

25 mm ~ 80 mm

-

Thickness:

-

1.2mm - 4.0mm

-

High welding power:

-

300kw

-

Pipe shape:

-

Square Round Rectangle LTZ Profile

-

Cutting system:

-

Saw blade cutting / HSS blade cutting

-

High frequency system:

-

Sanyi brand / Thermatool brand/ZSHC Brand

-

Auxiliary equipment:

-

Diagnostic device ; Inkjet printer ; Zinc spraying device

Quick Details

-

Pipe Material:

-

Carbon steel

-

Production Capacity:

-

0-90 m/min

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Sinopower

-

Voltage:

-

Customized

-

Power:

-

25 Kw ~ 600 Kw

-

Dimension(L*W*H):

-

Base on customer's land size

-

Weight:

-

60 kg, 45 tons ~ 90 tons

-

Production name:

-

ERW pipe mill production line

-

Pipe diameter:

-

25 mm ~ 80 mm

-

Thickness:

-

1.2mm - 4.0mm

-

High welding power:

-

300kw

-

Pipe shape:

-

Square Round Rectangle LTZ Profile

-

Cutting system:

-

Saw blade cutting / HSS blade cutting

-

High frequency system:

-

Sanyi brand / Thermatool brand/ZSHC Brand

-

Auxiliary equipment:

-

Diagnostic device ; Inkjet printer ; Zinc spraying device

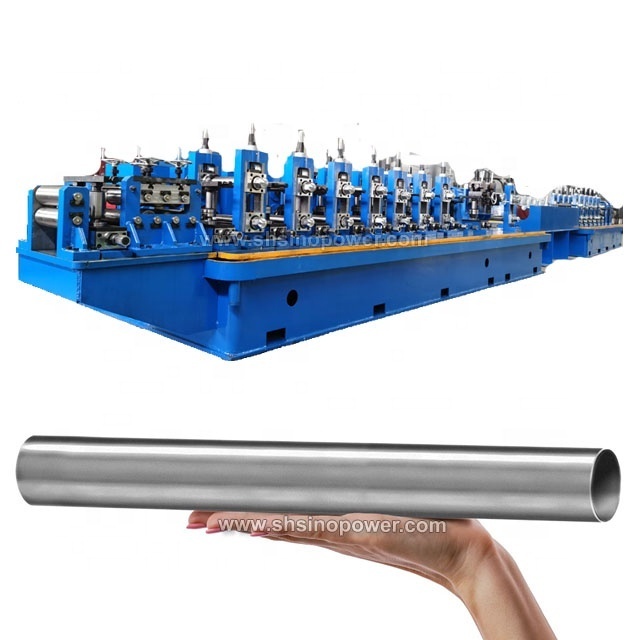

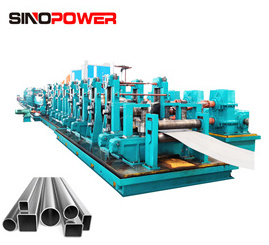

Steel pipe making machine.

ERW welded pipe / tube making.

Used for building, scaffolding, furniture, cars, water, gas...etc

Coil slitting machine.

Slit metal coil to certain width strip.

Apply to HR, CR, GI, PPGI, ST37, ST52, SS...etc

Why Choose us?

1.30 years in metal processing equipment development

2.15 years export experience, serves hundreds clients in 40 countries

3.Top engineer team, advanced production process, maximize returns for client.

4.24 hours online service, excellent service system

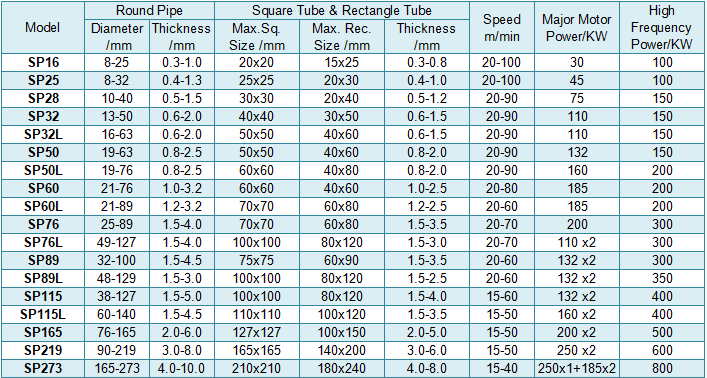

High frequency welded pipe making machine is the main equipment for the welded steel tube production line with decoiler, strip feeding, roller forming and sizing, high frequency solid welding, cutting and stock. Below are detailed specification of our pipe mill line. GI Carbon Steel Iron Pipe Making Machine Production Line 8-219 mm welding steel ERW Pipe Mill.

1: Which kind of pipe can be produced by our ERW pipe mill ?

1. Oil & Gas Pipes 7. Wire and Cable Protection Pipe

2. Heating Pipe 8. Structural Support Steel Pipe

3. Low-pressure Process Pipeline 9. Industrial Steel Pipes

4. Low Pressure Fire Fighting Pipeline 10. Decoration Pipe

5. Sewage Pipes 11. Water Pipe

6. Steel Scaffolding Pipe 12. Building pipe

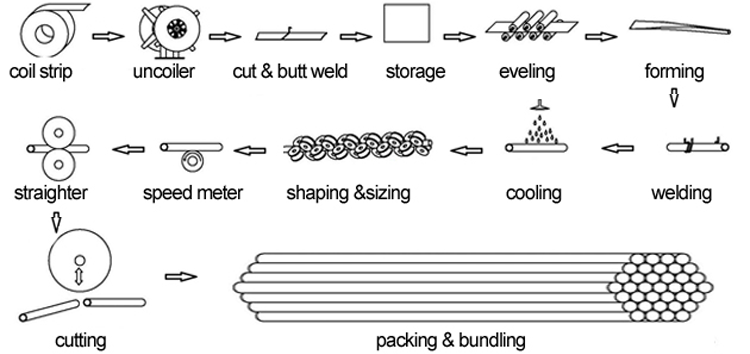

2. Flow chart of our MS Iron pipe making machine production line

Standard flow chart of ISO/CE MS Iron Pipe Making Machine Production Line 8-219 mm ERW Pipe Mill:

Step 1: Uncoiler

Step 2: Shearing butt welding

2 Types: Automatic & Manual

Function: Shear the end of each strip coil, then welding them together, so that pipe making production line can be continue production.

Step 3: Strip Accumulator

Function: storage strip to keep continue production.

2 Types: Horizontal / Vertical

Advantage: Horizontal type can be larger storage. Vertical type is much cheap and small space occupied.

Step 4: Forming Section.

Function: forming the tube from strip

Advantage:

>Advanced forming technical

>One-stage molding platform

>Reliable quality gear box

>Siemens Beide motor

Step 5: High Frequency Welding

Function: Welding the pipe , different thickness & diameter, the power of the HF welding machine welder

Our advantage: We choose the China best welder: Sanyi brand.

Step 6: Sizing Section

Function: sizing the tube to precise size

Advantage:

>Advanced sizing technical

>One-stage molding platform

>Reliable quality gear box and Siemens Beide motor

>High precision, low error of the pipe size

Step 7: Flying saw / Cold Saw

Function: cutting the ERW pipe mill line tube to right length.

Fly saw: easy to operation, low investment.

Cold saw: no noise, no burr cutting precision and cross section.

3. MS Iron Pipe Making Machine Production Line Details Pictures

Relying on superior products quality, Sino Power Group have successfully supplied world-class products and service to over 40 countries and areas around the world, such as: Poland, Spain, Russia, Yugoslavia, Ukraine, Turkey, Egypt, Saudi Arabia, India, Vietnam, Malaysia, Thailand, the Philippines, Pakistan, kazakhstan, Ethiopia, etc.

Below is our standard series of our tube making machine, we also accept customized .

Pls click here send us Inquire

Back to Homepage

Mob/WhatsApp: +86 15821640176

Wechat: +86 15821640176

Email:tessie(at)shsinopower.com