- Product Details

- {{item.text}}

Quick Details

-

Design Printing:

-

No printing

-

Material:

-

PE

-

Feature:

-

Heat-Resistant

-

Use:

-

Warning

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

dasheng

-

Model Number:

-

1.0

-

Thickness:

-

tba

-

Type:

-

Waterproof Membrane

-

Application:

-

Anti-corrosion for oil, gas, waste water pipelines

-

Installation:

-

By hand or with a wrapping machine

-

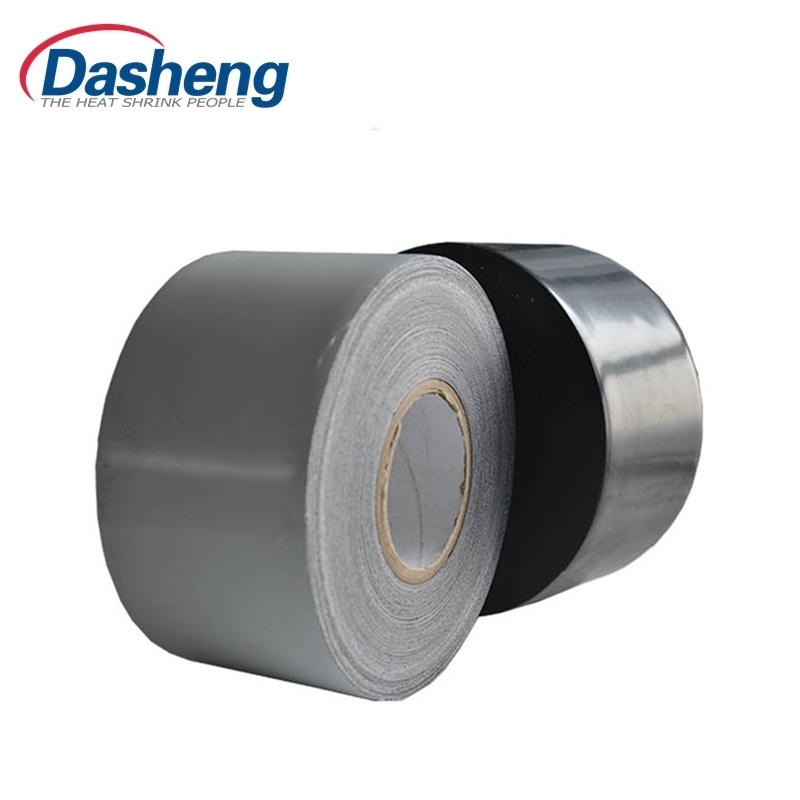

Color:

-

Black

Quick Details

-

Adhesive:

-

Rubber

-

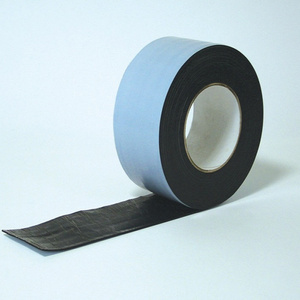

Adhesive Side:

-

Double Sided

-

Adhesive Type:

-

Pressure Sensitive, Water Activated, Hot Melt

-

Design Printing:

-

No printing

-

Material:

-

PE

-

Feature:

-

Heat-Resistant

-

Use:

-

Warning

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

dasheng

-

Model Number:

-

1.0

-

Thickness:

-

tba

-

Type:

-

Waterproof Membrane

-

Application:

-

Anti-corrosion for oil, gas, waste water pipelines

-

Installation:

-

By hand or with a wrapping machine

-

Color:

-

Black

T400 Cold-applied 3ply Tape

For corrosion protection of oil, gas, petrochemical, and waste water underground or overhead pipelines.

Construction: four-layer system

Internal Adhesive layer: Butyl rubber

External Adhesive layer: Butyl rubber

Film backing: Special blend of stabilized polyolefines

Interleaf: Anti-adhesive film treated with silicone

•Excellent bonding between adhesive and carrier film via co-extruded intermediate layer.

•Mechanically highly resistant tape system.

•Practically impermeable to water vapour and oxygen.

•Resistant to soil bacterial and soil electrolyte.

•Compatible with coating from PE, PP, FBE, PU, CTE and Bitumen and ext… .

•

A Total Coating System with

:

High adhesion and shear resistance

Resistance to corrosion disbondment

High electrical resistance

High dielectric strength

High corrosion protection for steel substrates

|

3ply tape |

T480, T4100 |

||

|

Physical Properties |

Test Method |

T480 Typical Value |

|

|

English |

Metric |

||

|

Color film backing

|

-- |

black(grey/green)

|

|

|

Thickness Carrie film

|

ASTM D 1000 |

12.0 mil

|

0.30mm

|

|

Total thickness |

32.0 mil |

0.80 mm |

|

|

Tensile strength |

ASTMD1000 |

70 lbs/in |

120 N/cm |

|

Elongation at break |

ASTMD1000 |

650% |

|

|

Peel strength to primed steel at 23 ℃ at 50 ℃ |

EN 12068

|

274.5 lbs/in

|

30 N/cm

|

|

Peel strength tape to tape at 23

℃

|

EN 12068

|

228 lbs/in

|

25 N/cm

|

|

Dielectric strength |

ASTMD149 |

35 Kv |

|

|

Insulation??? Resistance |

EN 12068 |

108 ohm·m 2 |

|

|

Water Vapor Transmission Rate ( 24h ) |

ASTM E 96 |

0.01g/100sq in/24h |

0.1g/100sq mm/24h |

|

Brittleness temperature |

DIN53372 |

-51±39 |

-46±4 ℃ |

|

Water Absorption |

ASTM D 570 |

0.08 % |

|

|

Impact resistance at 23'' |

EN 12068 |

15 J |

|

|

Cathodic disbandment at 23°c

|

EN 12068 |

15 mm

|

|

|

Lap shear strength at 50 ℃ |

EN 12068 |

0.05 N/mm2 |

|

* All information contained in this technical data sheet is to be used as a guide and is subject to change without notice. Products can be produced according to given specification. Please contact us for further information and confirmation.