FEETECH STS3215M 7.4V 19KG.CM Plastic Case Metal Gear Magnetic Encoder Double shaft TTL Serial Bus Servo

specifically designed for applications that require a lot of strong and complex actuation, such as humanoid robots, hexapod robots, and robotic arms. these servos are capable of 360°continuous rotation while still offering position control over an effective range of 360°. RS485 4P interface that is used to configure and control the servo and get feedback about position, speed, and temperature. Multiple servos can be daisy-chained on the same serial bus.

- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

STS3215

-

Size:

-

50*34.5*28mm

-

Product name:

-

360 degree rotation servo

-

Certificate:

-

ROHS

-

Function:

-

Magnetic Encoder

-

Description:

-

Potentionmeter 360°

-

Feature:

-

TTL Level Multi Drop

-

Torque:

-

20 kg

-

voltage:

-

6V~12V

-

Application:

-

Robotics

-

Keyword:

-

RS485

-

Power:

-

Battery

Quick Details

-

Use:

-

Vehicles & Remote Control Toys

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

FEETECH

-

Model Number:

-

STS3215

-

Size:

-

50*34.5*28mm

-

Product name:

-

360 degree rotation servo

-

Certificate:

-

ROHS

-

Function:

-

Magnetic Encoder

-

Description:

-

Potentionmeter 360°

-

Feature:

-

TTL Level Multi Drop

-

Torque:

-

20 kg

-

voltage:

-

6V~12V

-

Application:

-

Robotics

-

Keyword:

-

RS485

-

Power:

-

Battery

Related Products

Product Description

Product Introduction

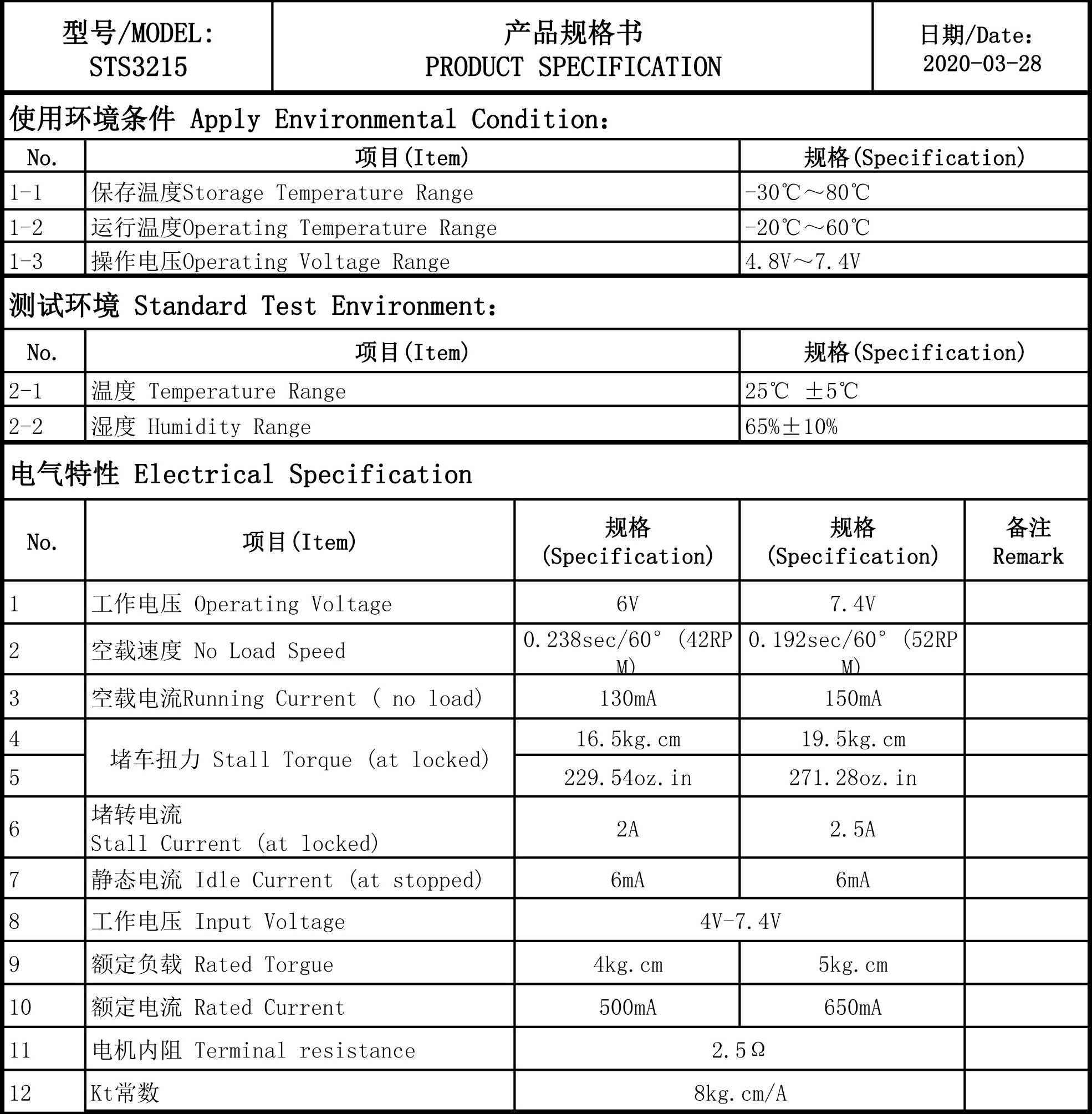

SKU:STS3215

Product Name:7.4V 19KG.CM Plastic Case Metal Gear Magnetic Encoder Double shaft TTL Serial Bus Servo

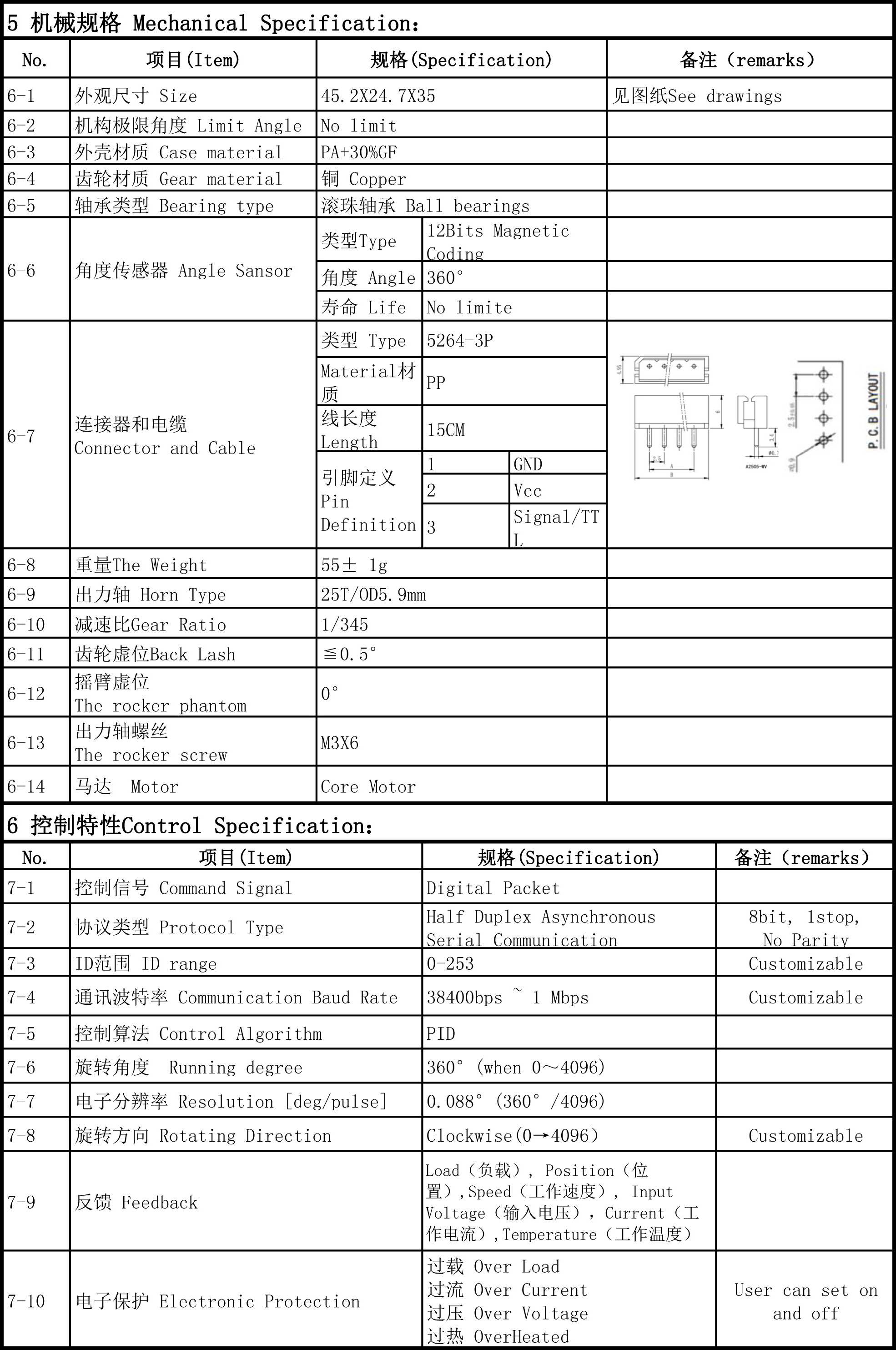

Appearance size:45.2X24.7X35mm(See the blueprint)

Stall Torque:19.5kg.cm@7.4V

Stall Speed:52RPM@7.4V

Feedback: load / position / speed / voltage / current / temperature

Electronic protection: overheat / overcurrent / overvoltage / overload protection

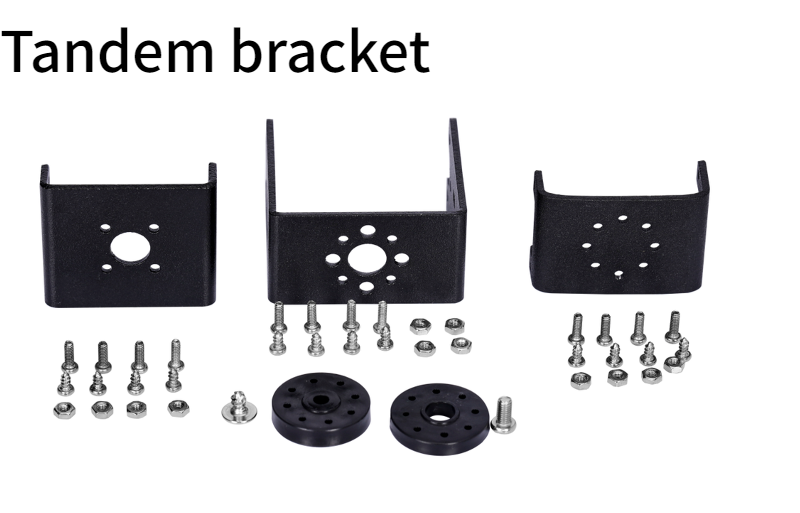

Structural Features:

The shell adopts engineering plastic shell with higher strength,Optimize the center distance,More compact overall structure, The servo gear adopts 1:345 copper Gear combination,higher torque;At the same Torque,compare with the standrd servo size,it looks lower profile(5mm),The body adopts double axis structure design,The structural characteristics of the circle lined solid,Wiring mode of double outgoing cables with metal Principal deputy servo horns,It is suitable for application in quadruped robot, snake robot, desktop robot, humanoid robot and mechanical arm.

Electronic control Function:

1.Acceleration start stop function: speed and acceleration value can be set, motion effect is more gentle.

2.High precision, 360 degree absolute position 4096 bit precision, the highest position resolution is 0.088 degrees, if the control is 90 degrees, input 4096 / 360 * 90 = 1024, if the control is 180 degrees, input 4096 / 360 * 180 = 2048, so as to calculate.

3.There are four working mode switching (mode 0 position servo, mode 1 speed closed-loop, mode 2 speed open-loop, mode 3 step servo).

1)、Mode 0:Location mode, the default mode. In this mode, 360 degree absolute angle control can be realized. Support acceleration movement.

2)、Mode 1:Speed closed-loop, in the programming interface, the operation mode is set to 1, switch to speed closed-loop mode, and enter the corresponding speed in the speed column to run.

3)、Mode 2:Speed open-loop, in the programming interface, the operation mode is set to 2, switch to speed open-loop mode, and enter the corresponding time in the time column to run.

4)、Mode3:Step mode: in the programming interface, the maximum / minimum angle limit is set to 0, and the operation mode is set to 3. Switch to step mode. Enter the position in the position bar to step towards the target position. Click the position again to continue to step in the same direction.

4、Multi turn mode, 360 degree absolute control and feedback, under the highest accuracy, the absolute position control can be plus or minus 7 turns, but the number of power cycles is not saved, only the absolute position feedback value is retained.

5、One key calibration, 360 degree angle installation at any position, (40 (decimal) address input 128 (decimal)) one key correction current position is the middle (2048 (decimal)).

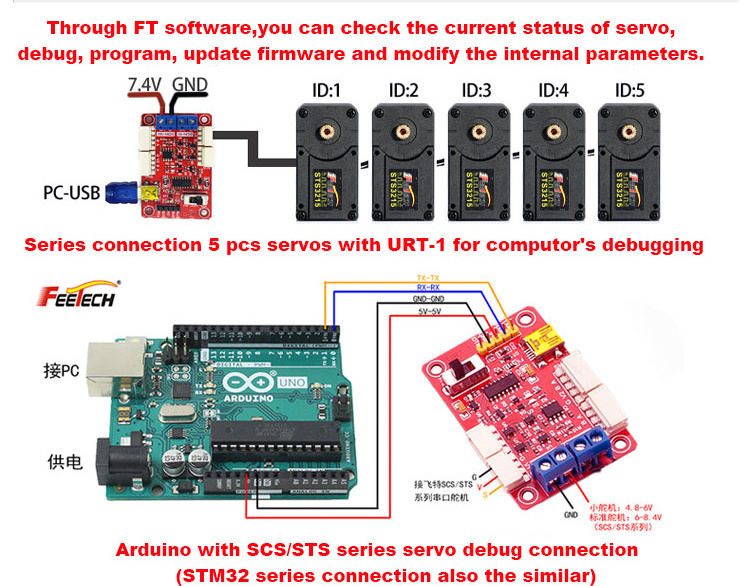

6、TTL communication level, half duplex asynchronous communication, bus protocol support to adjust read and write parameters, and add synchronous read function (send an instruction to receive the read back instruction from each servo on the bus in turn.)

7、Multiple protections, (overload, overcurrent, overvoltage, overheating, switch setting, condition parameter changing)

1)、Overload protection: through position detection, during the movement from the starting position to the target position, when the current position is detected to be not the target position after encountering the blocking of obstacles, the unloading force lasts for 2S (20% of the default blocking force). Until a new command is triggered, Release protection

2)、Overcurrent protection: through the set current value, check whether the current reaches the set current value. When it reaches the set current value, release the force (the default torque is 0). Until a new command is triggered, Release protection

3)、Over voltage protection: detect the current voltage value. If it exceeds the set voltage value, the alarm will display over-voltage.

4)、Overheat protection: detect the current motor temperature. If the temperature exceeds the set value, the alarm will display overheat.

8:Multiple feedback:

1)Load feedback: the current control output drives the voltage duty cycle of the motor, and the full scale is 1000 = 100% torque output.

2)Current feedback: The servo working current, 1 = 6.5mA

3)Voltage feedback: The servo working voltage,70=7V,0.1V

4)Temperature feedback: internal working temperature of current servo(measuring temperature)。

5)Speed feedback: feedback the speed of current motor rotation, and the number of steps in unit time (per second)

50steps/second=0.732RPM 1 step=0.088°

88 °/second=1000 steps/second=About 15RPM 1RPM=6°/second。

0.1Sec/60°=10/0.10RPM=100RPM

9、Open PID parameters.

-

Product performance description

Specification Overview:

FEETECH STS3215M 7.4V 19KG.CM Plastic Case Metal Gear Magnetic Encoder Double shaft TTL Serial Bus Servo.

|

Product Name

|

FEETECH STS3215M 7.4V 19KG.CM Plastic Case Metal Gear Magnetic Encoder Double shaft TTL Serial Bus Servo

|

|

|

Material

|

Magnetic coding&Core motor&Copper Gear.

|

|

|

Function

|

It is very suitable to replace traditional servo, as the joint, wheel and track drive of micro-robot, and can also be used for other simple positions or stepping control occasions.

|

|

|

Package

|

packed full accessory with metal horn*cable*screws and so on.

|

|

|

Advantages

|

1. Acceleration and termination

|

|

|

|

2.

It can be install at any angle

|

|

|

|

3. Multicircle and Large Angle

|

|

|

|

4. Data Feedback,Mutiple protection

|

|

|

|

5. Parameter Debuging of Open PID motor

|

|

|

FEETECH STS3215M Characteristic:

|

|

|

|

1.Sensor

|

Magnectic Coding 12 bit sensor measurement position

|

|

|

2.High resolution

|

Contactless 12 bit encoder(360 degree 0.088 degrees)

|

|

|

3.Serial Bus

|

Support serial bus Daisy chain,254 ID address optional

|

|

|

4.position control mode

|

Rotatable 0-360 and multi circle arbitrary angle

|

|

|

5.speed control mode

|

Can control the direction of continuous rotation

|

|

|

6.PWM control Mode

|

Output constant force,positive and negative direction control

|

|

Details Images

The shell adopts engineering plastic shell with higher strength,Optimize the center distance,More compact overall structure

Double outgoing (5264-3) connector, simplified wiring connection

Double shaft for both the top shaft and the bottom shaft with Metal horns,very easy and convenient to install on your machine to operatiing.

Product Usage

-

Market Positioning

Low price, high performance - cost effective

TTL simple bus

A、 Main educational robots, such as quadruped robots, humanoid robots, snake robots.

B. Service robots, such as desktop robots.

-

-

Product Application introduction

-

STS3215M can be used in logistics, urban security, medical, military, education, commercial robot ,smart home and so on,Feetech committed to providing customized servo and industry solutions for enterprise users.

Contact Us

Packing&Shipping

Packing:

-Servo×1PCS

-Servo horn with Screw setX1bag

-1pcs Servo Cable

-Servo×1PCS

-Servo horn with Screw setX1bag

-1pcs Servo Cable

Company Introduction

Shenzhen FEETECH RC Model Co., Ltd was established in 2011,

We are a research and development, customization, production and sale of high-quality servos for artificial intelligence products company,

Based on the realization of the servo transition curve constant acceleration technology and precision manufacturing technology,

take hold in intelligent modular products which are more suitable for position control,

The products are related to logistics, urban security, medical, military, education, AR industry, commercial robot and so on.

It is committed to providing customized servo and industry solutions for enterprise users, and has been highly recognized and widely adopted by the partners.

Since its development, Feetech has established a deep cooperative relationship with famous universities, Chinese Academy of Sciences, University of Hong Kong ,

and major emerging enterprises.Feetech make arduous efforts to promote the artificial intelligence industry development .

The brand of “FEETECH” is based on the concepts of Flying, Excellent, Efficient and Technology.

We look forward to working with you to build a better future together!

Our Services & Strength

Specialized in ODM and OEM and Custom Made

Shipping

We adopt EXW term. Generally, we choose, DHL, FedEx, EMS or UPS as our forwarder. Of course, you can choose your own most favorable forwarder, and we would provide the freight bill according to the quantity and weight of the total products, Freight Collect can also be acceptable.

Payment

We adopt T/T payment methods. After we receive your payment, we will arrange shipment. All banking charges and interest are charged to purchasers.

Warranty Procedure

As long as you choose to use FEETECH products, you can enjoy the warranty service that we provide. Please print our Repair Request Form (.PDF, .DOC) and fill it out in its entirety, being as comprehensive as possible, in order to receive the best possible service.

Warranty Period

All FEETECH products are warranted against defects for a period of one (1) years from the date of purchase. During this period we will repair or replace (at our discretion) any defective products. You should always retain your original receipt as proof of the date of purchase.

Shipping

We adopt EXW term. Generally, we choose, DHL, FedEx, EMS or UPS as our forwarder. Of course, you can choose your own most favorable forwarder, and we would provide the freight bill according to the quantity and weight of the total products, Freight Collect can also be acceptable.

Payment

We adopt T/T payment methods. After we receive your payment, we will arrange shipment. All banking charges and interest are charged to purchasers.

Warranty Procedure

As long as you choose to use FEETECH products, you can enjoy the warranty service that we provide. Please print our Repair Request Form (.PDF, .DOC) and fill it out in its entirety, being as comprehensive as possible, in order to receive the best possible service.

Warranty Period

All FEETECH products are warranted against defects for a period of one (1) years from the date of purchase. During this period we will repair or replace (at our discretion) any defective products. You should always retain your original receipt as proof of the date of purchase.

FAQ

Q:How about your quality?

A:Our quality will be good,and the goods have been checked and tested one by one before shipping.

Q:How long for the delivery once we place order?

A:The lead time is declded the item you ordered and the quantity.

For normal order,the lead time is about in 5-7 days,

If big quantity or OEM,the lead time will be some days more.

Q:The price you are offering is with shipping costs included?

A:The price does not include the shipping cost.We offer several

shipping solutions,make sure customers choose the most economical one.

Q:Do you have After-Sales Service?

A:Of course,We have special department to do it,and if you have any technology

problem,our eingeer will give your answer.

A:Our quality will be good,and the goods have been checked and tested one by one before shipping.

Q:How long for the delivery once we place order?

A:The lead time is declded the item you ordered and the quantity.

For normal order,the lead time is about in 5-7 days,

If big quantity or OEM,the lead time will be some days more.

Q:The price you are offering is with shipping costs included?

A:The price does not include the shipping cost.We offer several

shipping solutions,make sure customers choose the most economical one.

Q:Do you have After-Sales Service?

A:Of course,We have special department to do it,and if you have any technology

problem,our eingeer will give your answer.

Hot Searches