- Product Details

- {{item.text}}

Quick Details

-

Production Capacity:

-

99%

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

TZY

-

Voltage:

-

220v/380v

-

Dimension(L*W*H):

-

1400*760*1270mm

-

Weight:

-

95kg

-

Model:

-

SL-AB1

-

Power:

-

Motor , gasoline engine

-

Capacity:

-

1-1.5t/h

-

Net Weight:

-

95kg

-

Overall Size:

-

1400*760*1270mm

-

Function:

-

peeler and thresher

-

Feature:

-

High Clean Rate

-

Shelling rate:

-

95~99%

-

Raw material:

-

Carbond Steel

-

Suit for:

-

Farm and Sellers

-

After Warranty Service:

-

Video technical support, Online support, Spare parts, Field maintenance and repair service

-

Local Service Location:

-

None

-

After-sales Service Provided:

-

Free spare parts, Field installation, commissioning and training, Field maintenance and repair service, Video technical support, Online support

-

Certification:

-

CE ISO

Quick Details

-

Marketing Type:

-

New Product 2021

-

Type:

-

thresher,sheller

-

Use:

-

corn,maize

-

Production Capacity:

-

99%

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

TZY

-

Voltage:

-

220v/380v

-

Dimension(L*W*H):

-

1400*760*1270mm

-

Weight:

-

95kg

-

Model:

-

SL-AB1

-

Power:

-

Motor , gasoline engine

-

Capacity:

-

1-1.5t/h

-

Net Weight:

-

95kg

-

Overall Size:

-

1400*760*1270mm

-

Function:

-

peeler and thresher

-

Feature:

-

High Clean Rate

-

Shelling rate:

-

95~99%

-

Raw material:

-

Carbond Steel

-

Suit for:

-

Farm and Sellers

-

After Warranty Service:

-

Video technical support, Online support, Spare parts, Field maintenance and repair service

-

Local Service Location:

-

None

-

After-sales Service Provided:

-

Free spare parts, Field installation, commissioning and training, Field maintenance and repair service, Video technical support, Online support

-

Certification:

-

CE ISO

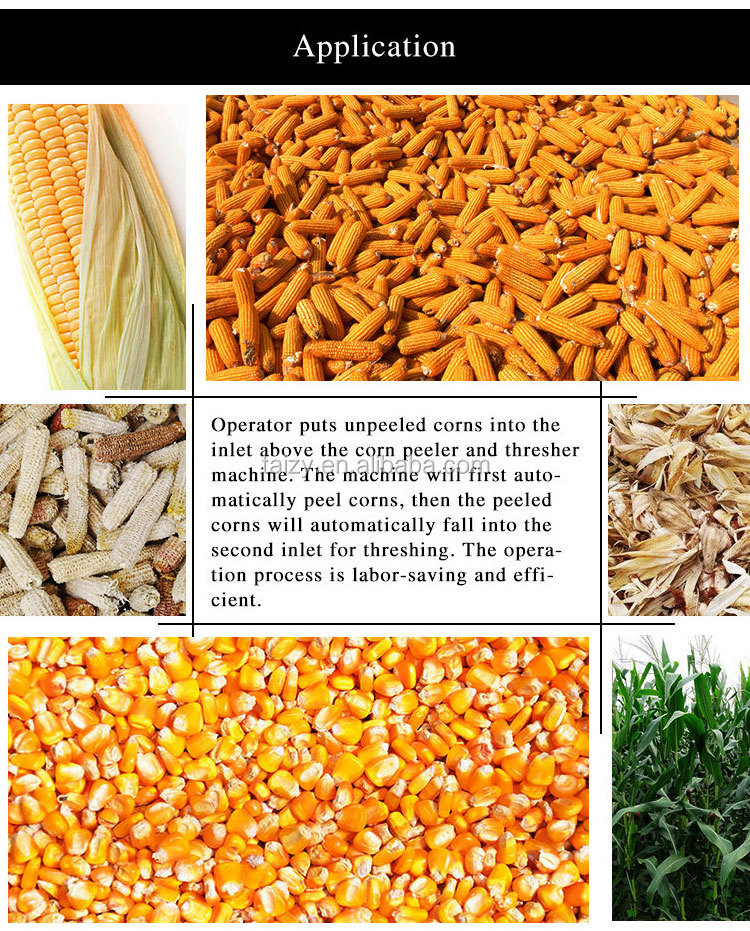

Best Selling Products Corn Peeler And Thresher Machine

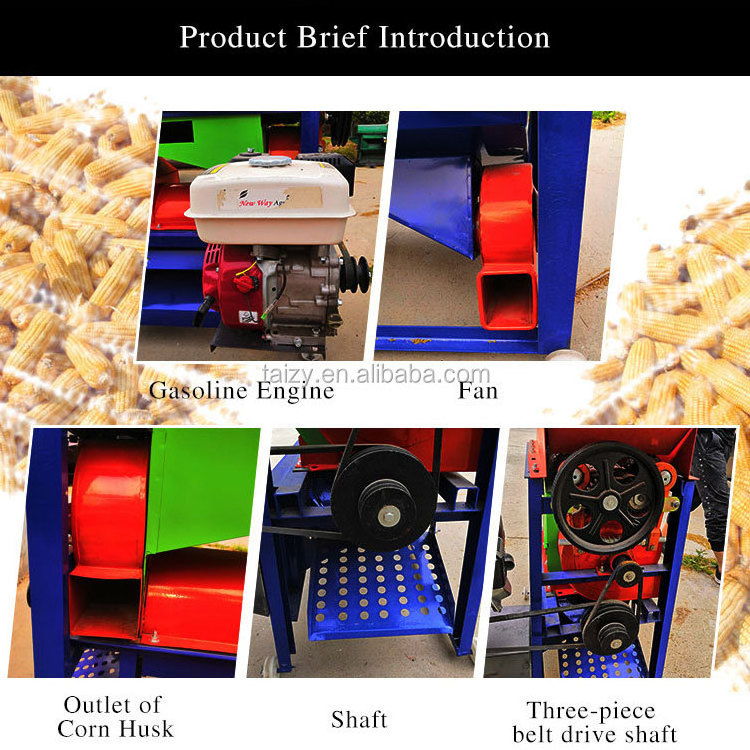

Brief of corn sheller machine

This is the n ewest corn peeling and threshing machine. It is mainly used for threshing maize husks and corn seeds . The corn granules are separated from the corn kernels by running the peeler and the thresher. The maize peeler and sheller make your working have more f aster operation, high efficiency, and low breakage rate ,so that tired work easier and simpler.

|

Model |

SL-AB1 |

|

Power |

2.2kw Motor , 170F gasoline engine , 6-8HP diesel engine (you can choose one) |

|

Capacity |

1-1.5t/h |

|

Net Weight |

95kg |

|

Overall Size |

1400*760*1270mm |

Advantages of corn thresher machine

1. This corn peeling and thresher is small in size, light in weight, and easy to move and use.

2.special peeling shaft,so maize husk does not wrap around the shaft.

3.Special peeling shaft, so the corn husk does not wrap around the shaft, and p arts are not easily damaged .

4.This machine can perform 1-1.5 tons of corn peeling and threshing work per hour, and can efficiently remove impurities and preserve the integrity of the corn kernels.

5.Farmers or manufacturers can choose three different power machines according to their needs, 2.2kw motor, gasoline engine or diesel engine.

6.The machine is green and environmentally friendly, with high speed, low noise, high safety and stable operation.

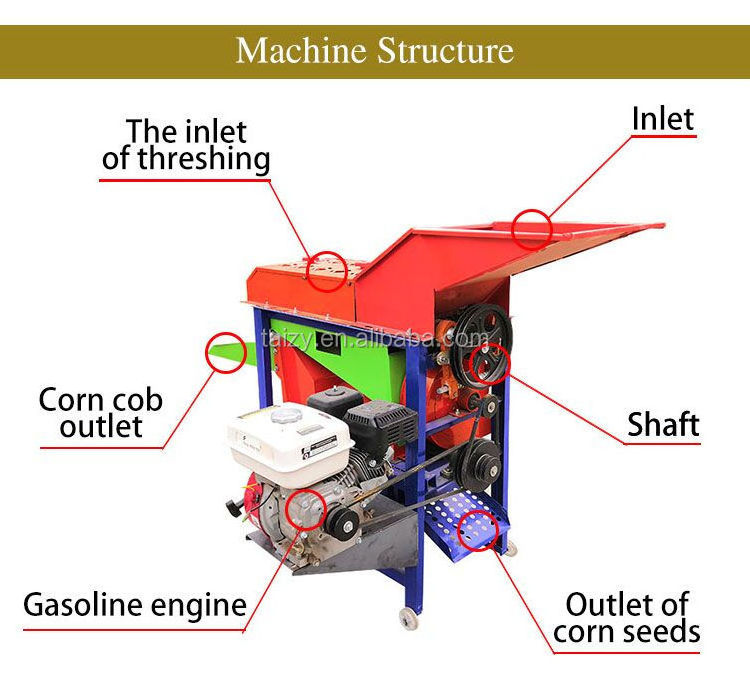

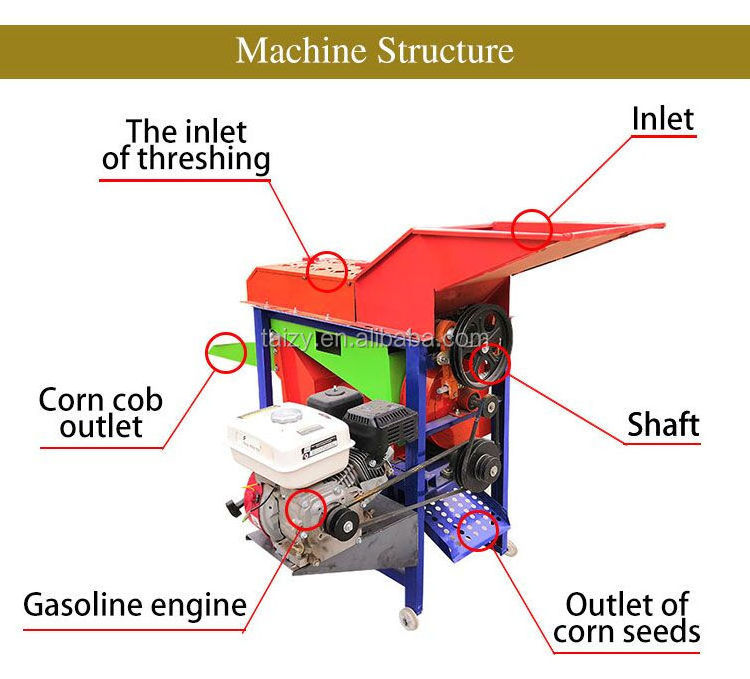

Working principle of corn peeling machine

1. First put the corn into the machine inlet, reach the peeler part for peeling, and the corn skin peels off by rotating, rubbing, squeezing and pushing the drum body.

2. Second the maize enters threshing machine section and is impacted in the rotor and drum rotating at high speed, and the grain is separated by the sieve hole to complete the threshing.

3. After the threshing is completed, through vibration of the screen and blow of the fan, the corn seeds and the corn cob are discharged from two different outlets at the tail of the machine, and the corn husk is blown by fan.

4. There is a baffle in the lower part of the feeding inlet to prevent the corn particles from falling off and hurting people.

Other similar machines

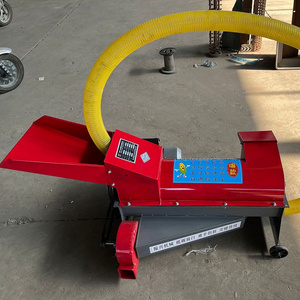

Real scenes