- Product Details

- {{item.text}}

Quick Details

-

EINECS No.:

-

230-391-5

-

Place of Origin:

-

China

-

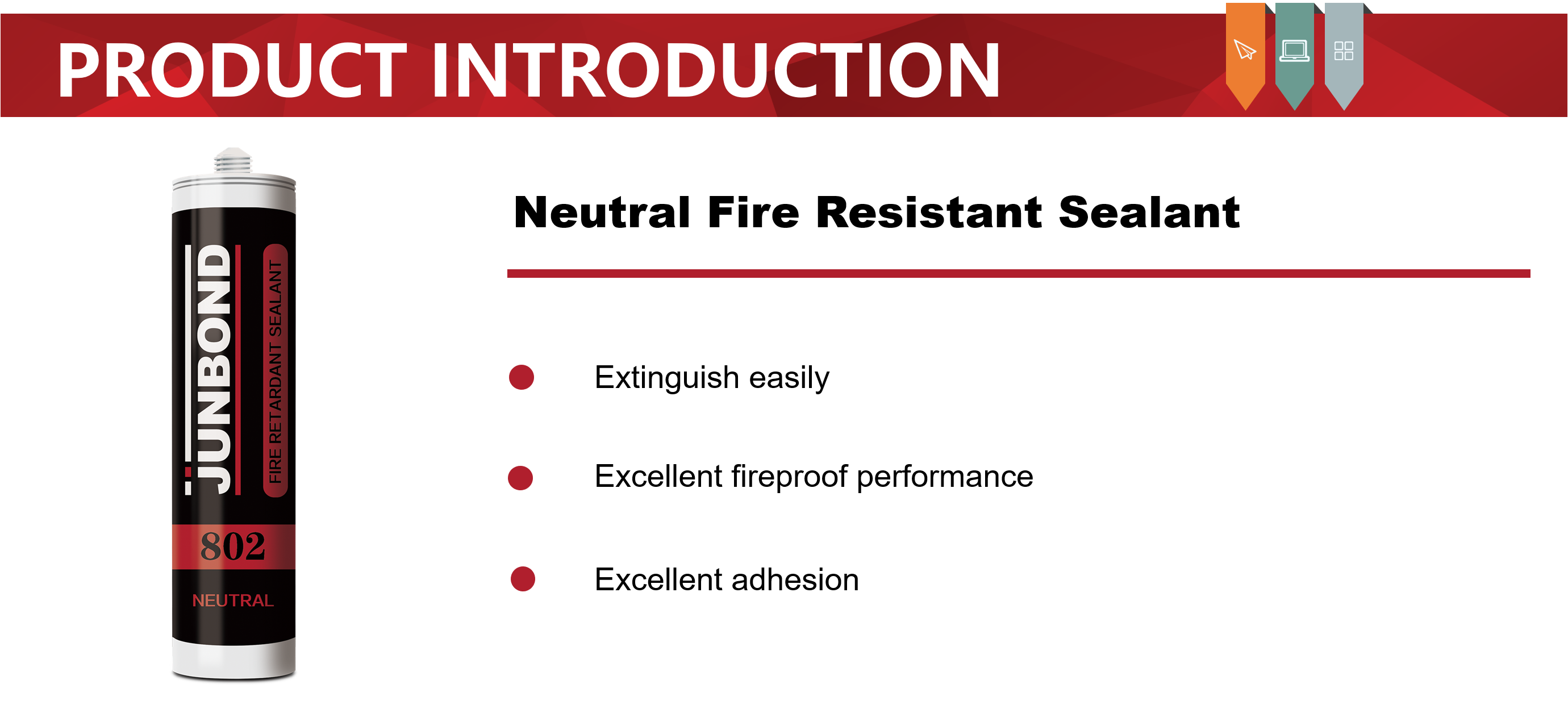

Brand Name:

-

Junbond

-

Model Number:

-

JB802

-

Type:

-

Fireproof Silicone Sealant

-

Color:

-

White

-

Application:

-

Fireproof Silicone Sealant

-

Product name:

-

Silicone Sealants Non Flammable

-

Appearance:

-

Sealant

-

Shelf life:

-

12 Months

-

Package:

-

Tube

-

Keywords:

-

Free Samples And Low Price Fireproof

-

Viscosity:

-

Strong

-

Volume:

-

300ml

-

Quality:

-

Guarantee

Quick Details

-

CAS No.:

-

7085-85-0

-

Other Names:

-

Silicone Sealant

-

MF:

-

Mixture

-

EINECS No.:

-

230-391-5

-

Place of Origin:

-

China

-

Brand Name:

-

Junbond

-

Model Number:

-

JB802

-

Type:

-

Fireproof Silicone Sealant

-

Color:

-

White

-

Application:

-

Fireproof Silicone Sealant

-

Product name:

-

Silicone Sealants Non Flammable

-

Appearance:

-

Sealant

-

Shelf life:

-

12 Months

-

Package:

-

Tube

-

Keywords:

-

Free Samples And Low Price Fireproof

-

Viscosity:

-

Strong

-

Volume:

-

300ml

-

Quality:

-

Guarantee

China top 10 silicone sealant manufacturer 789 heat resistant roof leaking silicone sealant fireproof weatherproof sealant

Product Feature:

This product is mainly made of polymer materials, after curing at room temperature, the sealant has a certain elasticity and good adhesion, and has excellent resistance to vibration, cracking, high temperature, aging and fire resistance, easy to use and install.

Main Application :

1. Mainly used in housing, hotels, shopping malls, fire doors, ventilation ducts, duct inlets, pipe threads, pipe flanges,

electronic instruments, electrical appliances, machinery, petrochemicals, light industry, construction and other industries

2. Suitable for bonding and sealing of galvanized steel plates, aluminum alloys, stainless steel, corner flanges, ceramics,

engineering plastics, wood, cement products.

3. Other uses tested and applicable

How to use:

1. Before construction, a test of the adhesion of the sealant to the substrate should be carried out to confirm the suitability of the product.

2. The substrate should be thoroughly cleaned with solvent or suitable cleaning agent, kept dry and glued within 30 minutes after cleaning.

3. When gluing, ensure that the gap is completely filled, so that the gluing layer is dense and in close contact with the

surface of the substrate, and the gluing gap should be repaired within 5 minutes after gluing.

4. Suitable application temperature range 5°C to 40°C.

Warnings:

1. Use in a well-ventilated environment.

2. Use solvents in accordance with the appropriate safety regulations.

3. Keep the product out of the reach of children.

4. If uncured sealant melts your eyes, wash them immediately with water or seek medical attention.

Executive Standard: JC/T885- -2016

This product is mainly made of polymer materials, after curing at room temperature, the sealant has a certain elasticity and good adhesion, and has excellent resistance to vibration, cracking, high temperature, aging and fire resistance, easy to use and install.

Main Application :

1. Mainly used in housing, hotels, shopping malls, fire doors, ventilation ducts, duct inlets, pipe threads, pipe flanges,

electronic instruments, electrical appliances, machinery, petrochemicals, light industry, construction and other industries

2. Suitable for bonding and sealing of galvanized steel plates, aluminum alloys, stainless steel, corner flanges, ceramics,

engineering plastics, wood, cement products.

3. Other uses tested and applicable

How to use:

1. Before construction, a test of the adhesion of the sealant to the substrate should be carried out to confirm the suitability of the product.

2. The substrate should be thoroughly cleaned with solvent or suitable cleaning agent, kept dry and glued within 30 minutes after cleaning.

3. When gluing, ensure that the gap is completely filled, so that the gluing layer is dense and in close contact with the

surface of the substrate, and the gluing gap should be repaired within 5 minutes after gluing.

4. Suitable application temperature range 5°C to 40°C.

Warnings:

1. Use in a well-ventilated environment.

2. Use solvents in accordance with the appropriate safety regulations.

3. Keep the product out of the reach of children.

4. If uncured sealant melts your eyes, wash them immediately with water or seek medical attention.

Executive Standard: JC/T885- -2016

|

Test Method

|

Property

|

Unit

|

Standard

|

Result

|

|

GB/T 13477 (ISO 7390)

|

Slump

|

mm

|

≤3

|

0

|

|

GB/T 13477 (ISO 8394)

|

Extrusion rate

|

ml/min

|

≥80

|

482

|

|

GB/T 13477 (ASTM D 2377)

|

Tack free time

|

h

|

≤3

|

0.7

|

|

GB/T 13477 (ISO 7389)

|

Exension recovery

|

%

|

≥40

|

87

|

|

GB/T 13477 (ISO 11600)

|

Movement capability

|

%

|

±12.5

|

±12.5

|

|

GB/T 13477 (ISO 9046)

|

Adhesion after extension and compression cycle at fixed temp

|

|

No failure

|

No failure

|

|

GB/T 13477 (ISO 8339)

|

Elongation at break after immersion

|

%

|

≥40

|

60

|

|

GB/T 13477 (ISO 10563)

|

Weight loss

|

%

|

≤25

|

5.4

|

|

GB/T 2408

|

Fire retardant rate

|

|

FV-0

|

FV-0

|

|

GB 23864

|

Fire resistance

|

|

A3

|

A3

|

Hot Searches